Amathuluzi okulinganisa ukunemba kwe-Granite (ababusi besikwele, ama-straightedges, ama-Angle rule, njll.) adlala indima ebalulekile emikhakheni eminingi ephezulu ngenxa yokunemba kwawo okuphezulu, ukuzinza okuphezulu nokumelana nokugqwala okuqinile.

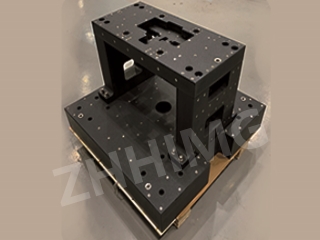

Ekucutshungulweni kwemishini okunembayo, isetshenziselwa ukulinganisa ukuqondisa kwamareyili angumhlahlandlela kanye nokucaba kwamathebula okusebenza kumathuluzi omshini we-CNC, izikhungo zomshini nezinye izinto zokusebenza. Nge-coefficient yokunweba okushisayo ephansi njengo-(4-8) ×10⁻⁶/℃, ingamelana nomthelela wokukhuphuka kwezinga lokushisa ngesikhathi sokusebenza kwamathuluzi omshini. Uma uhlola izingxenye ezinembayo, indawo yayo enoburhalarhume obuphansi ngeke iklwebhe umsebenzi futhi imelana nokugqwala kukawoyela.

Izimboni ze-aerospace nezokuvikela zinezidingo eziqinile zokunemba. Amathuluzi okulinganisa e-granite asetshenziselwa ukulinganisa ukulungiswa kwe-tenon yama-blade enjini yendiza kanye nokuhlola izindawo zokukhwelana zamakhebhi ezicitshwayo, njll. Isici sayo sokumanzisa okuphezulu singamunca ukudlidliza endaweni yokusebenzela. Inokuqina okuqinile kwamakhemikhali futhi ingakwazi ukuzivumelanisa nemvelo yenqubo ekhethekile ye-workshop ye-aerospace, iqinisekisa ukunemba kokukhiqiza kwezingxenye ezibalulekile.

Emkhakheni wokukhiqiza ama-electronics kanye ne-semiconductor, amathuluzi okulinganisa ama-granite asetshenziselwa ukulinganisa ama-rail angumhlahlandlela ezintweni zokusebenza ezifana nemishini ye-photolithography nemishini yokudayela eyi-wafer, kanye nokuhlolwa kwezinto zokupakisha ze-chip. Isici sayo sokungabi bikho kwe-ion yensimbi igwema ukungcolisa indawo yokusebenzela ehlanzekile ye-semiconductor, iqinisekisa ukunemba kwe-nano-scale lithography kanye nekhwalithi ye-SMT patch soldering.

Ukuhlola i-Metrology nezikhungo zocwaningo zisebenzisa amathuluzi okulinganisa egwadle njengezilinganiso zokulinganisa amanye amathuluzi okulinganisa ensimbi. Zinokugcinwa kokunemba okuhle kakhulu kwesikhathi eside, futhi ukuguquka kwesicaba ngemva kweminyaka eyi-10 yokusetshenziswa kungu-≤±0.5μm/m. Iphinde isetshenziswe njengereferensi yokulinganisa enembayo kusayensi yezinto zokwakha kanye nokuhlolwa kobunjiniyela bokubona.

Ngaphezu kwalokho, amathuluzi okulinganisa egwadle asetshenziswa futhi ekukhiqizeni amathuluzi ezokwelapha namathuluzi okubona, njengokulinganisa amalunga amarobhothi okuhlinzwa kanye nezisekelo zamabakaki wetheleskopu yezinkanyezi, ukuze kuqinisekiswe ukuthi okokusebenza kufeza ukunemba kokuma kwe-sub-millimeter kanye nemiphumela yokubona engaguquki. Ngokusebenza okuvelele, amathuluzi okulinganisa ukunemba kwe-granite abe "itshe legumbi elinembile" lokukhiqiza okuphezulu.

Isikhathi sokuthumela: May-22-2025