Emkhakheni wokukhiqiza ngokunemba, umbono ovamile oyiphutha ukuthi "ubuningi obuphezulu = ukuqina okuqinile = ukunemba okuphezulu". Isisekelo se-granite, esinobukhulu obungu-2.6-2.8g/cm³ (7.86g/cm³ sensimbi ephonswe), sifinyelele ukunemba okudlula okwe-micrometer noma ngisho nama-nanometer. Ngemuva kwalesi simo "esiphikisanayo" kukhona ukusebenzisana okujulile kwe-mineralogy, mechanics kanye namasu okucubungula. Okulandelayo kuhlaziya izimiso zayo zesayensi ezivela ezicini ezine ezinkulu.

1. Ubuningi ≠ Ukuqina: Indima ebalulekile yesakhiwo sezinto ezibonakalayo

Isakhiwo sekristalu "sezinyosi zemvelo" segranite

I-granite yakhiwe ngamakristalu amaminerali afana ne-quartz (SiO₂) kanye ne-feldspar (KAlSi₃O₈), ahlanganiswe eduze yizibopho ze-ionic/covalent, akha isakhiwo esifana ne-honeycomb esixhumene. Lesi sakhiwo siyinika izimfanelo ezihlukile:

Amandla okucindezela afana nalawo ensimbi ephothiwe: afinyelela ku-100-200 mpa (100-250 mpa yensimbi ephothiwe empunga), kodwa i-modulus enwebekayo iphansi (70-100 gpa vs 160-200 gpa yensimbi ephothiwe), okusho ukuthi mancane amathuba okuthi iguqulwe ngepulasitiki ngaphansi kwamandla.

Ukukhishwa kwemvelo kokucindezeleka kwangaphakathi: I-Granite iye yaguga eminyakeni engamakhulu ezigidi zezinqubo ze-geological, futhi ukucindezeleka okusele kwangaphakathi kufinyelela ku-zero. Lapho insimbi epholisiwe ipholiswa (ngesilinganiso sokupholisa > 50℃/s), ukucindezeleka kwangaphakathi okuphezulu njengo-50-100 mpa kukhiqizwa, okudingeka kususwe ngokunamathisela okwenziwe. Uma ukwelashwa kungaphelele, kuthambekele ekuguqukeni ngesikhathi sokusetshenziswa isikhathi eside.

2. Isakhiwo sensimbi "esineziphambeko eziningi" sensimbi ephonswe

Insimbi ephothiwe iyi-iron-carbon alloy, futhi inezinkinga ezifana ne-flake graphite, ama-pores kanye ne-shrinkage porosity ngaphakathi.

I-matrix yokuqhekeka kwe-Graphite: I-Graphite ye-Flake ilingana "ne-microcracks" yangaphakathi, okuholela ekunciphiseni okungu-30%-50% endaweni yangempela yensimbi ephonswe umthwalo. Nakuba amandla okucindezela ephezulu, amandla okuguquguquka aphansi (yi-1/5-1/10 kuphela yamandla okucindezela), futhi ithambekele ekuqhekekeni ngenxa yokuhlushwa kokucindezeleka kwendawo.

Ukusabalala kobuningi obuphezulu kodwa okungalingani: Insimbi ehlanganisiwe iqukethe ikhabhoni engu-2% kuya ku-4%. Ngesikhathi sokusatshalaliswa, ukuhlukaniswa kwezakhi zekhabhoni kungabangela ukuguquguquka kobuningi okungu-±3%, kuyilapho i-granite inokufana kokusatshalaliswa kwamaminerali okungaphezu kuka-95%, okuqinisekisa ukuzinza kwesakhiwo.

Okwesibili, inzuzo yokunemba kobuningi obuphansi: ukucindezelwa okubili kokushisa nokudlidliza

"Inzuzo engokwemvelo" yokulawula ukuguqulwa kokushisa

I-coefficient yokwanda kokushisa iyahlukahluka kakhulu: i-granite ingu-0.6-5×10⁻⁶/℃, kanti insimbi ecijile ingu-10-12×10⁻⁶/℃. Thatha isisekelo samamitha ayi-10 njengesibonelo. Uma izinga lokushisa lishintsha ngo-10℃:

Ukwandiswa kanye nokufinyela kwe-granite: 0.06-0.5mm

Ukwandiswa kanye nokufinyela kwensimbi ephonswe ngensimbi: 1-1.2mm

Lo mehluko wenza i-granite icishe ibe "zero deformation" endaweni elawulwa kahle izinga lokushisa (njenge-±0.5℃ endaweni yokusebenzela ye-semiconductor), kuyilapho insimbi ephonswe ngensimbi idinga uhlelo olwengeziwe lokunciphisa ukushisa.

Umehluko wokuqhuba ukushisa: Ukuqhuba ukushisa kwe-granite kungu-2-3W/(m · K), okuyi-1/20-1/30 kuphela yaleyo yensimbi ephonswe (50-80W/(m · K)). Ezimweni zokushisa kwemishini (njengalapho izinga lokushisa lemoto lifinyelela ku-60℃), i-gradient yokushisa ebusweni be-granite ingaphansi kuka-0.5℃/m, kuyilapho eyensimbi ephonswe ingafinyelela ku-5-8℃/m, okuholela ekukhuleni okungalingani kwendawo futhi kuthinte ukuqondeka kwesitimela sokuqondisa.

2. Umphumela "wokunciphisa imvelo" wokucindezela ukudlidliza

Indlela yokuhlakazeka kwamandla omngcele wokusanhlamvu kwangaphakathi: Ukuqhekeka okuncane kanye nokushelela komngcele wokusanhlamvu phakathi kwamakristalu e-granite kungahlakaza amandla okudlidliza ngokushesha, ngesilinganiso sokudambisa esingu-0.3-0.5 (kanti ngensimbi ephonswe kungu-0.05-0.1 kuphela). Ukuhlolwa kukhombisa ukuthi ekudlidlizeni okungu-100Hz:

Kuthatha imizuzwana engu-0.1 ukuthi ubukhulu be-granite bubole bufike ku-10%

Insimbi ephothiwe ithatha imizuzwana engu-0.8

Lo mehluko wenza i-granite ikwazi ukuzinza ngokushesha emishinini ehamba ngesivinini esikhulu (njengokuskena kwekhanda lokumboza elingu-2m/s), kugwema iphutha "lamamaki okudlidliza".

Umphumela ophambene wesisindo se-inertial: Ubuningi obuphansi busho ukuthi isisindo sincane ngevolumu efanayo, futhi amandla e-inertial (F=ma) kanye nomfutho (p=mv) wengxenye ehambayo aphansi. Isibonelo, lapho uhlaka lwe-granite gantry olungamamitha ayi-10 (olunesisindo samathani ayi-12) lusheshiswa lube yi-1.5G uma kuqhathaniswa nohlaka lwensimbi olubunjiwe (amathani angama-20), isidingo samandla okushayela sincishiswa ngo-40%, umthelela wokuqalisa uyehla, futhi ukunemba kokubeka kuthuthukiswa kakhulu.

Iii. Intuthuko ekuqondeni "okungaxhomekeki kubantu abaningi" kobuchwepheshe bokucubungula

1. Ukuzivumelanisa nezimo ekucubungulweni okunembile kakhulu

Ukulawulwa kokugaya nokupholisha "kwezinga lekristalu": Nakuba ubulukhuni begranite (6-7 esikalini se-Mohs) buphakeme kunobensimbi ephostiwe (4-5 esikalini se-Mohs), isakhiwo sayo samaminerali sifana futhi singasuswa nge-athomu ngokusebenzisa i-diamond abrasive + magnetorheological polishing (ubukhulu bokupholisha okukodwa < 10nm), kanye nobulukhuni bomphezulu i-Ra ingafinyelela ku-0.02μm (izinga lesibuko). Kodwa-ke, ngenxa yokuba khona kwezinhlayiya ezithambile ze-graphite ensimbini ephostiwe, "umphumela we-furplough" uvame ukwenzeka ngesikhathi sokugaya, futhi ubulukhuni bomphezulu kunzima ukuba buphansi kune-Ra 0.8μm.

Inzuzo "yokucindezeleka okuphansi" yomshini wokugaya we-CNC: Lapho kucutshungulwa i-granite, amandla okusika ayi-1/3 kuphela yalawo ensimbi ephonswe (ngenxa yobuningi bayo obuphansi kanye ne-modulus encane enwebekayo), okuvumela isivinini esiphezulu sokujikeleza (ukujikeleza okungu-100,000 ngomzuzu) kanye namazinga okuphakelayo (5000mm/min), kunciphisa ukuguguleka kwamathuluzi nokuthuthukisa ukusebenza kahle kokucubungula. Icala elithile lomshini we-five-axis libonisa ukuthi isikhathi sokucubungula se-granite guide rail grooves sifushane ngo-25% kunesensimbi ephonswe, kuyilapho ukunemba kuthuthukiswa kube yi-±2μm.

2. Umehluko "ekuphumeleleni okuhlanganisiwe" kwamaphutha okuhlangana

Ukusabela kweketanga kwesisindo sengxenye esincishisiwe: Izingxenye ezifana nama-motor kanye ne-guide rails ezihambisana nezisekelo eziphansi zingakhanyiswa ngasikhathi sinye. Isibonelo, lapho amandla e-linear motor encishisiwe ngo-30%, ukukhiqizwa kwayo kokushisa kanye nokudlidliza nakho kwehla ngokufanele, kwakha umjikelezo omuhle "wokunemba okuthuthukisiwe - ukusetshenziswa kwamandla okuncishisiwe".

Ukugcinwa kokunemba kwesikhathi eside: Ukumelana nokugqwala kwe-granite kuphindwe ka-15 kunokwensimbi ephonswe nge-alkali (i-quartz imelana nokuguguleka kwe-asidi ne-alkali). Endaweni ye-semiconductor acid inkungu, ushintsho lobukhali bomphezulu ngemva kweminyaka eyi-10 yokusetshenziswa lungaphansi kuka-0.02μm, kuyilapho insimbi ephonswe nge-alkali idinga ukugaywa nokulungiswa njalo ngonyaka, ngephutha elihlanganisiwe elingu-±20μm.

Iv. Ubufakazi Bezimboni: Isibonelo Esihle Kakhulu Sobuningi Obuphansi ≠ Ukusebenza Okuphansi

Imishini yokuhlola i-semiconductor

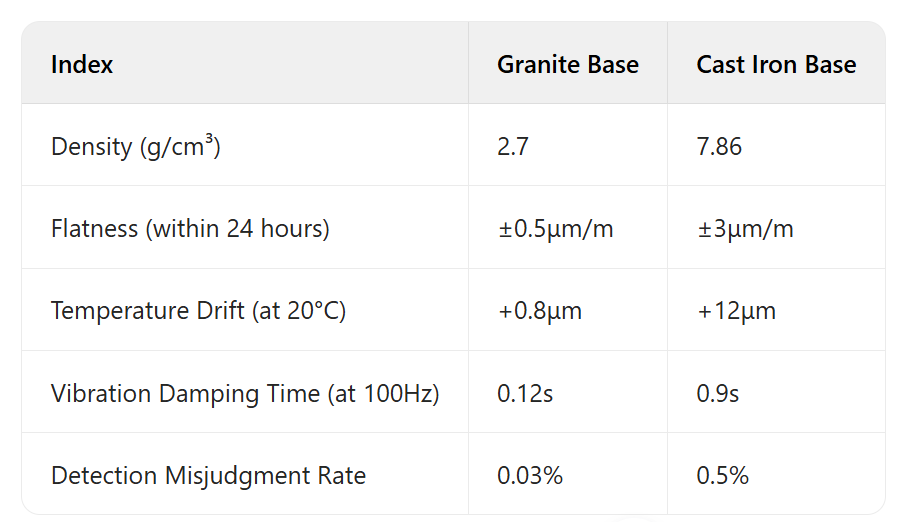

Idatha yokuqhathanisa yesikhulumi esithile sokuhlola i-wafer:

2. Izinsimbi zokukhanya eziqondile

I-bracket ye-infrared detector ye-NASA's James Webb Telescope yenziwe nge-granite. Kungokusebenzisa kahle ukuminyana kwayo okuphansi (ukunciphisa umthwalo wesathelayithi) kanye nokwanda okuphansi kokushisa (okuzinzile emazingeni okushisa aphansi kakhulu angu--270℃) lapho ukunemba kokuqondana kwe-nano-level kuqinisekiswa, kuyilapho ingozi yokuthi insimbi ephonswe ibe buthakathaka emazingeni okushisa aphansi isuswa.

Isiphetho: Ukusungula izinto ezintsha "okuphambene nomqondo ovamile" kwisayensi yezinto ezibonakalayo

Inzuzo yokunemba kwezisekelo ze-granite empeleni itholakala ekunqobeni kwe-logic yezinto ezibonakalayo "kokufana kwesakhiwo > ubuningi, ukuzinza kokushaqeka kokushisa > ukuqina okulula". Akukhona nje ukuthi ubuningi bayo obuphansi abuzange bube yiphuzu elibuthakathaka, kodwa futhi bufinyelele igxathu ekuqondeni ngezinyathelo ezifana nokunciphisa i-inertia, ukwenza ngcono ukulawula ukushisa, kanye nokuzivumelanisa nokucubungula okunembile kakhulu. Lesi simo sembula umthetho oyinhloko wokukhiqiza okunembile: izakhiwo zezinto ezibonakalayo ziyibhalansi ephelele yamapharamitha anobukhulu obuningi kunokuba kube ukuqongelela okulula kwezinkomba ezizodwa. Ngokuthuthuka kwe-nanotechnology kanye nokukhiqizwa okuluhlaza, izinto ze-granite ezinobukhulu obuphansi kanye nokusebenza okuphezulu zichaza kabusha umbono wezimboni "wobunzima" kanye "nokukhanya", "obuqinile" kanye "nokuguquguquka", zivula izindlela ezintsha zokukhiqiza okuphezulu.

Isikhathi sokuthunyelwe: Meyi-19-2025