Emhlabeni ohlale uvela wezinto zikagesi, ukwenziwa kwamabhodi esekethe aphrintiwe (PCBs) kuyinqubo ebalulekile edinga ukunemba nokwethembeka. Izingxenye zomshini we-Granite zingezinye zamaqhawe angaqashiwe ale nqubo yokukhiqiza eyinkimbinkimbi. Lezi zingxenye zidlala indima ebalulekile ekuqinisekiseni ukunemba nekhwalithi yama-PCB, adingekayo ukuze izinto zikagesi zisebenze kahle.

Yaziwa ngokuzinza nokuqina kwayo okukhethekile, igwadule liyinto efanelekile yezingxenye zemishini ezisetshenziswa ekwenziweni kwe-PCB. Izakhiwo zemvelo ze-Granite, njenge-coefficient ephansi yokwanda okushisayo kanye nokumelana nokuguqulwa, ziyenza ibe ukukhetha okuphezulu kubakaki, okokulungisa, namathuluzi. Uma ukunemba kubalulekile, i-granite inganikeza inkundla ezinzile, inciphise ukudlidliza kanye nokuguquguquka kokushisa okungaba nomthelela omubi kuzinqubo ezibucayi ezihilelekile ekukhiqizeni i-PCB.

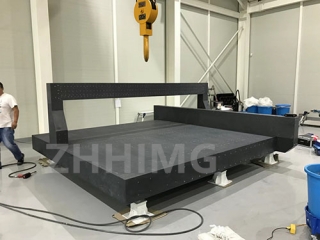

Ngesikhathi senqubo yokukhiqiza ye-PCB, ukunemba okuphezulu kuyadingeka kuzo zonke izigaba ezifana nokubhoboza, ukugaya nokunamathisela. Izingxenye zomshini we-granite ezifana namathebula omsebenzi we-granite nezinsimbi zokulinganisa ziqinisekisa ukuthi umshini usebenza ngaphakathi kokubekezelelana okuqinile. Lokhu kunemba kubalulekile ukuze kugcinwe ubuqotho bephethini yesifunda nokuqinisekisa ukuthi izingxenye zibekwe ngokunembile ebhodini.

Ukwengeza, ukuqina kwe-granite kusiza ukunweba impilo yemishini yokukhiqiza. Ngokungafani nezinye izinto ezingase ziguge noma ziwohloke ngokuhamba kwesikhathi, i-granite igcina ubuqotho bayo besakhiwo, inciphisa isidingo sokushintshwa nokugcinwa njalo. Lokhu akugcini nje ukwandisa ukukhiqiza, kodwa futhi kunciphisa izindleko zokusebenza kubakhiqizi.

Kafushane, izingxenye zemishini ye-granite zibalulekile emkhakheni wokukhiqiza i-PCB. Izakhiwo zayo eziyingqayizivele zinikeza ukuzinza nokunemba okudingekayo ekukhiqizeni i-electronics yekhwalithi ephezulu. Njengoba isidingo samadivayisi kagesi ayinkimbinkimbi futhi ahlangene siqhubeka nokwanda, indima ye-granite ekuqinisekiseni ukwethembeka nokusebenza kwe-PCB izobaluleka kakhulu.

Isikhathi sokuthumela: Jan-14-2025