Emkhakheni wezindiza, ukunemba kokucubungula izingxenye kuhlobene ngqo nokusebenza, ukuphepha kanye nokuthembeka kwezindiza. Kusukela ezingxenyeni eziyinhloko zezinjini zezindiza kuya kumathuluzi okunemba kwamasathelayithi, yonke ingxenye idinga ukuhlangabezana nezindinganiso zokukhiqiza eziphakeme kakhulu. Kulo mncintiswano wokunemba okuphelele, amathuluzi okulinganisa i-granite, anezakhiwo zawo eziyingqayizivele zomzimba kanye nezinzuzo zobuchwepheshe, abe "izikhali eziyimfihlo" ezibalulekile embonini yokukhiqiza izindiza, enikeza isiqinisekiso esiqinile sokucutshungulwa kwezingxenye ngokunemba okukhulu.

Ukusebenza okuvelele kwamathuluzi okulinganisa i-granite: abaqaphi bemvelo bokunemba

I-Granite iyitshe lemvelo elakhiwe ngezinqubo ze-geological eminyakeni engamakhulu ezigidi. Isakhiwo sayo sangaphakathi siminyene futhi sifana, futhi inezici eziningi ezifanele ukucutshungulwa ngokunemba okukhulu. Okokuqala, i-coefficient yokwanda kokushisa kwe-granite iphansi kakhulu, ngokuvamile isukela ku-5 kuya ku-7×10⁻⁶/℃. Lesi sici siyenza ikwazi ukugcina izinga eliphezulu lokuzinza kobukhulu endaweni yokucubungula enezinguquko ezinkulu zokushisa. Ekucutshungulweni kwezingxenye zezindiza, ukushisa okukhiqizwa ukusebenza kwemishini kanye nokuguquguquka kokushisa kwemvelo akunakugwenywa. Amathuluzi okulinganisa enziwe ngezinto ezivamile angabangela amaphutha okulinganisa ngenxa yokwanda kokushisa kanye nokufinyela, kuyilapho amathuluzi okulinganisa i-granite cishe engathinteki yizinguquko zokushisa futhi angahlala enikeza idatha yokulinganisa enembile nethembekile, eqinisekisa ukuthi ukunemba kokucubungula akuphazanyiswa yizici zokushisa.

Okwesibili, i-granite inokumelana okuhle kakhulu nokuguguleka kanye nobunzima obuphezulu, kanye nobunzima be-Mohs obufika ku-6 kuya ku-7. Ngesikhathi sezinqubo zokulinganisa ezivamile, amathuluzi okulinganisa i-granite awagugi futhi angagcina ukunemba kwawo isikhathi eside. Ukucutshungulwa kwezingxenye zezindiza kuvame ukudinga inani elikhulu lemisebenzi yokulinganisa. Ukumelana nokuguguleka kwamathuluzi okulinganisa i-granite kuwenza akwazi ukugcina ubukhulu kanye nezimo eziqondile ngisho nangemva kokusetshenziswa isikhathi eside, okunciphisa kakhulu imvamisa yokushintsha amathuluzi kanye nezindleko zokulungisa.

Ngaphezu kwalokho, i-granite nayo inokusebenza okuhle kakhulu kokuvimbezela kokudlidliza. Ema-workshop okukhiqiza izindiza, ukusebenza kwemishini ehlukahlukene yokucubungula kudala ukudlidliza ngamazinga ahlukahlukene, okungathinta ukunemba kokulinganisa. Amathuluzi okulinganisa i-granite angamunca futhi anciphise ukudlidliza kwangaphandle ngempumelelo, ahlinzeke ngendawo ezinzile yenqubo yokulinganisa futhi aqinisekise ukunemba nokuthembeka kwemiphumela yokulinganisa.

Ukusetshenziswa okubalulekile kwamathuluzi okulinganisa i-granite ekucutshungulweni kwezingxenye zezindiza

Ukucutshungulwa kwezingxenye eziyinhloko zezinjini ze-aero

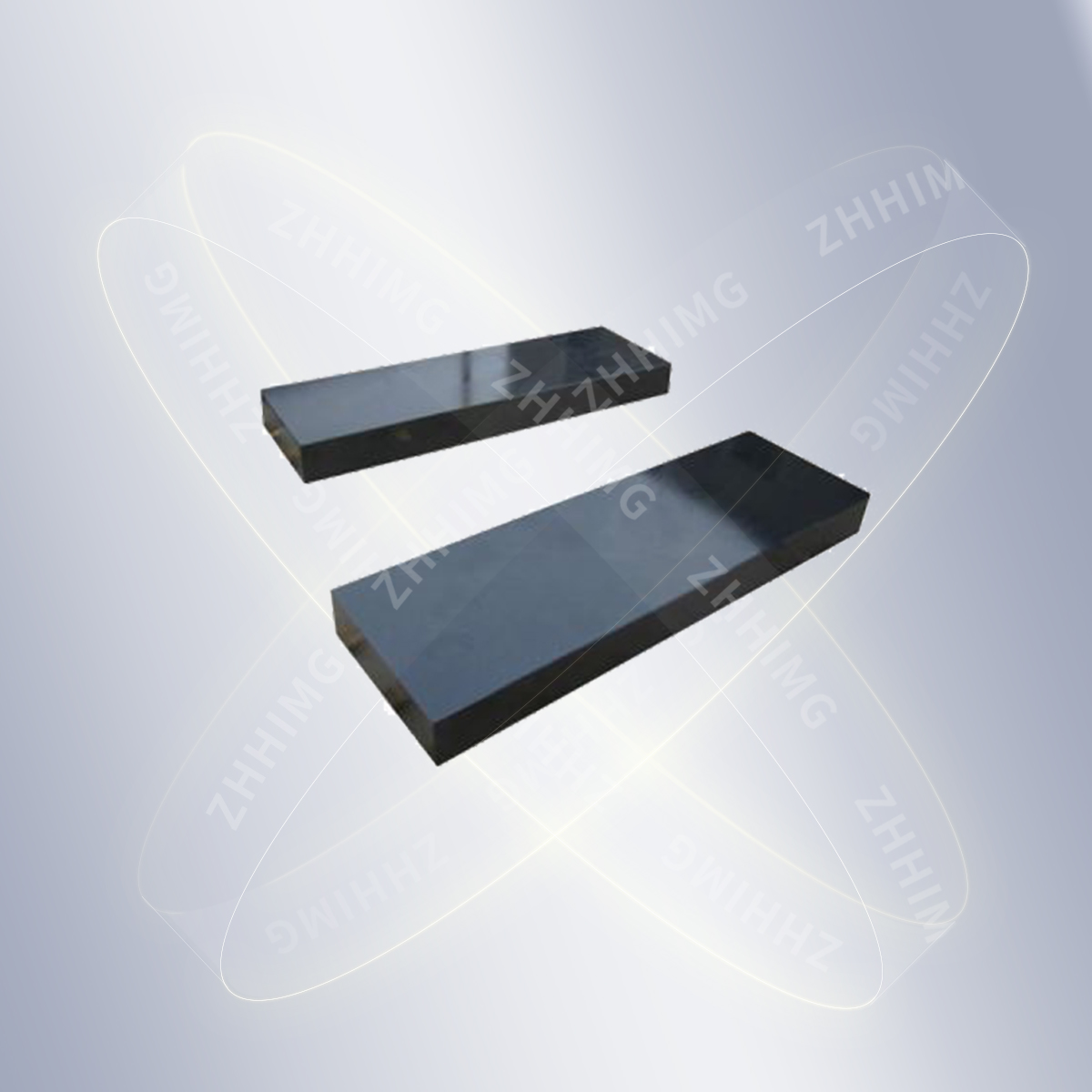

Njenge "inhliziyo" yendiza, injini yezindiza inezidingo eziphakeme kakhulu zokunemba kokucubungula izingxenye zayo. Isibonelo, ukuma nokunemba kobukhulu bama-blade enjini kuthinta ngqo ukusebenza kahle kanye nokujikijela kwenjini. Ngesikhathi sokucubungula ama-blade, amathuluzi okulinganisa i-granite asetshenziswa kabanzi ekulinganisweni nasekuhlolweni kobukhulu obubalulekile. Ipulatifomu ye-granite isebenza njengendawo yokulinganisa ebhekisela kuyo. Ukuthamba kwayo okuphezulu kakhulu (kufika ku-±0.005mm/m) kunganikeza inkomba enembile yokulinganisa iphrofayili ye-blade, kuqinisekiswe ukunemba kwemiphumela yokulinganisa. Ngokusebenzisa amathuluzi okulinganisa njengezisekelo ze-granite dial indicator kanye namabhulokhi e-granite gauge, abasebenzi bokucubungula bangalinganisa ngokunembile ubukhulu bama-blade, kufaka phakathi ubukhulu, ukugoba, kanye ne-torsion Angle, ngamaphutha alawulwa ezingeni le-micrometer noma ngisho ne-nanometer, ngaleyo ndlela kuqinisekiswe ukuthi ukusebenza kwe-aerodynamic kwama-blade kuhlangabezana nezidingo zomklamo.

Ukukhiqizwa kwezingxenye zesakhiwo sezindiza

Izingxenye zesakhiwo sezindiza ezifana nohlaka lwe-fuselage kanye nemishayo yamaphiko kudingeka zibe nezici zamandla aphezulu kanye nokukhanya, futhi ngesikhathi esifanayo, kunezidingo eziqinile zokunemba kobukhulu. Ngesikhathi sokucubungula lezi zingxenye zesakhiwo, amathuluzi okulinganisa i-granite asetshenziselwa ukuthola ukubekezelela ukuma kanye nesikhundla njengokuthamba, ukunemba kanye nokuma kwezingxenye. Ama-granite straightedges namabhokisi esikwele e-granite kanye namanye amathuluzi okulinganisa, anekhwalithi ephezulu yobuso kanye nesakhiwo esizinzile, angabona ngokunembile amaphutha amancane ezingxenye zesakhiwo, esiza abasebenzi bokucubungula ukulungisa ubuchwepheshe bokucubungula ngesikhathi esifanele futhi baqinisekise ukunemba kokuhlanganiswa kanye nokusebenza okuphelele kwezingxenye zesakhiwo. Isibonelo, ngesikhathi senqubo yokuhlanganisa uhlaka lwe-fuselage, ukusebenzisa amathuluzi okulinganisa i-granite ukuze kulinganiswe ngokunembile kungaqinisekisa ukunemba kokuxhumana phakathi kwengxenye ngayinye futhi kuthuthukise amandla aphelele kanye nokuzinza kwe-fuselage.

Ukukhiqizwa kwezinsimbi zokunemba kwesathelayithi

Amasathelayithi asebenza esikhaleni futhi kufanele abhekane nokushintsha okukhulu kwezinga lokushisa, imisebe nezinye izici zemvelo. Ngakho-ke, ukunemba kokukhiqiza kwezinsimbi zokunemba ezingaphakathi kwawo kubaluleke kakhulu. Amathuluzi okulinganisa i-granite adlala indima ebalulekile enqubweni yokukhiqiza izinsimbi zesathelayithi, asetshenziselwa ukukala nokulinganisa ukunemba kobukhulu kanye nendawo yezingxenye zezinsimbi. Ngenxa yokuqina kokushisa kanye nokunemba okuphezulu kwamathuluzi okulinganisa i-granite, ingaqinisekisa ukuthi izinsimbi zesathelayithi zigcina ukusebenza okunembile ngaphansi kwezimo ezahlukene zemvelo, inikeze iziqinisekiso ezithembekile zokuzulazula okunembile, ukuxhumana kanye nokuhlola kwesayensi kwamasathelayithi.

Amathuluzi okulinganisa i-granite asiza imboni yokukhiqiza izindiza ukuthi ifinyelele amazinga amasha

Ngokuthuthuka okuqhubekayo kobuchwepheshe bezindiza, izidingo zokunemba kokucubungula izingxenye ziya ngokuya ziphakama. Amathuluzi okulinganisa i-granite, ngezinzuzo zawo zokusebenza ezihlukile, ahlinzeka ngosekelo lobuchwepheshe oluthembekile lokucubungula izingxenye zezindiza ngokunemba okukhulu. Ngokusebenzisa amathuluzi okulinganisa i-granite, abakhiqizi bangathuthukisa ikhwalithi yomkhiqizo, banciphise izinga lokulahla, banciphise umjikelezo wokukhiqiza, ngaleyo ndlela bathuthukise ukuncintisana kwebhizinisi.

Esikhathini esizayo, ngentuthuko eqhubekayo yobuchwepheshe bokucubungula kanye nesidingo esikhulayo sokunemba, amathuluzi okulinganisa i-granite azodlala indima ebaluleke kakhulu emkhakheni wezindiza. Uma ehlanganiswa nobuchwepheshe bokulinganisa obuthuthukisiwe kanye nezinhlelo zokukhiqiza ezihlakaniphile, kuzothuthukisa kakhulu intuthuko yomkhakha wokukhiqiza izindiza ukuze kube nokunemba nokusebenza kahle okuphezulu, futhi kusize isintu ukuthi siqhubeke sihlola futhi siphumelele emkhakheni wezindiza.

Isikhathi sokuthunyelwe: Meyi-07-2025