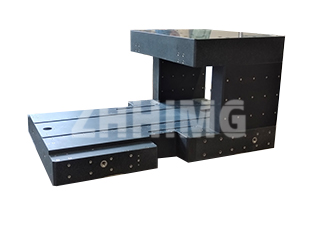

Ipulatifomu yokuhlola i-granite enembile iyisisekelo sokulinganisa okuphindaphindwayo nokunembile. Ngaphambi kokuba noma yiliphi ithuluzi le-granite—kusukela epuletini elilula lobuso kuya esikweleni esiyinkimbinkimbi—libhekwe njengelifanele ukusetshenziswa, ukunemba kwalo kumele kuqinisekiswe ngokuqinile. Abakhiqizi abanjengoZHONGHUI Group (ZHHIMG) banamathela ezindinganisweni zokulawula ikhwalithi eziqinile, beqinisekisa amapulatifomu kuwo wonke amamaki afana no-000, 00, 0, no-1. Lesi sitifiketi sincike ezindleleni zobuchwepheshe ezisunguliwe ezichaza ubucaba bangempela bobuso.

Ukunquma Ukuthamba: Izindlela Eziyinhloko

Inhloso eyinhloko yokuqinisekisa ipulatifomu ye-granite ukunquma iphutha layo lokuba yisicaba (FE). Leli phutha lichazwa ngokuyisisekelo njengebanga elincane phakathi kwezindiza ezimbili ezihambisanayo eziqukethe wonke amaphuzu endawo yokusebenza yangempela. Izazi ze-Metro zisebenzisa izindlela ezine eziqashelwayo ukunquma leli nani:

Izindlela Ezinezingqimba Ezintathu Nezinezingqimba: Lezi zindlela zinikeza ukuhlolwa okusebenzayo nokuyisisekelo kwesimo sobuso. Indlela Enezingqimba Ezintathu isungula indiza yokubhekisela yokuhlola ngokukhetha amaphuzu amathathu ahlukene kakhulu ebusweni, ichaza i-FE ngebanga eliphakathi kwezindiza ezimbili ezihambisanayo ezivalekile. Indlela Enezingqimba, evame ukusetshenziswa njengendinganiso yemboni, ngokuvamile isebenzisa amathuluzi ayinkimbinkimbi njengezinga le-elekthronikhi kanye nepuleti lebhuloho. Lapha, indiza yokubhekisela isethwe eceleni kwe-diagonal, inikeza indlela ephumelelayo yokubamba ukusatshalaliswa kwamaphutha okuphelele kulo lonke ubuso.

Indlela Encane Kakhulu Yokuphindaphinda Okubili (Izikwele Ezincane): Lena yindlela eqinile kakhulu ngokwezibalo. Ichaza i-reference plane njengeyona enciphisa isamba sezikwele zamabanga ukusuka kuzo zonke izindawo ezilinganisiwe kuya endizeni uqobo. Le ndlela yezibalo inikeza ukuhlolwa okuqondile kakhulu kobuthabala kodwa idinga ukucutshungulwa kwekhompyutha okuthuthukisiwe ngenxa yobunzima bezibalo ezihilelekile.

Indlela Yendawo Encane: Le ndlela ivumelana ngqo nencazelo yejiyometri yokuba flat, lapho inani lephutha linqunywa ububanzi bendawo encane kunazo zonke edingekayo ukuze kuhlanganiswe wonke amaphuzu obuso alinganisiwe.

Ukuqonda Ukufana: Iphrothokholi Yesikhombisi Sokudayela

Ngaphandle kokuba yisicaba okuyisisekelo, amathuluzi akhethekile njengezikwele ze-granite adinga ukuqinisekiswa kokufana phakathi kobuso bazo bokusebenza. Indlela yesikhombisi sokudayela ifaneleka kakhulu kulo msebenzi, kodwa ukuthembeka kwayo kuncike ngokuphelele ekusebenzeni ngokucophelela.

Ukuhlolwa kumele kwenziwe njalo epuletini lobuso elibhekiselwe ngokunemba okuphezulu, kusetshenziswa ubuso obunye bokulinganisa besikwele segranite njengereferensi yokuqala, eqondiswe ngokucophelela epulatifomu. Isinyathelo esibalulekile ukusungula amaphuzu okulinganisa ebusweni obuhlolwayo—lawa awahleliwe. Ukuqinisekisa ukuhlolwa okuphelele, indawo yokuhlola iyadingeka cishe ngama-5mm ukusuka emaphethelweni obuso, ihambisana nephethini yegridi ehlukaniswe ngokulinganayo phakathi nendawo, amaphuzu avame ukuhlukaniswa ngama-20mm kuya kuma-50mm. Le gridi eqinile iqinisekisa ukuthi yonke i-contour ihlelwe ngendlela ehlelekile yinkomba.

Okubaluleke kakhulu, lapho kuhlolwa ubuso obuphambene obuhambisanayo, isikwele segranite kumele sijikeleziswe ngama-degrees angu-180. Lokhu kuguquka kudinga ukucophelela okukhulu. Ithuluzi akumelwe neze lifakwe epuletini lokubhekisela; kumele liphakanyiswe ngokucophelela futhi libekwe kabusha. Le nqubo yokuphatha ebalulekile ivimbela ukuthintana okunamandla phakathi kwezindawo ezimbili ezihambisana kahle, okuvikela ukunemba okuzuzwe kanzima kwesikwele kanye nepulatifomu yokubhekisela isikhathi eside.

Ukufinyelela ukubekezelelana okuqinile kwamathuluzi asezingeni eliphezulu—njengezikwele ze-ZHHIMG ze-Grade 00 eziqondile—kuyisibonakaliso sezakhiwo zomzimba eziphakeme zomthombo we-granite kanye nokusetshenziswa kwalezi zinqubo ze-metrology eziqinile nezisunguliwe.

Isikhathi sokuthunyelwe: Novemba-03-2025