Njengoba ubuchwepheshe bokusika nge-laser bungena emkhakheni wama-laser e-femtosecond kanye ne-picosecond, izidingo zokuzinza kwemishini seziye zaba zimbi kakhulu. Ithebula lokusebenza, noma isisekelo somshini, akuseyona nje isakhiwo sokusekela; liyisici esichazayo sokunemba kohlelo. I-ZHONGHUI Group (ZHHIMG®) ihlaziya izizathu eziyisisekelo zokuthi kungani i-granite enobukhulu obuphezulu isibe ukukhetha okuphezulu, okungaxoxiswana ngakho ngaphezu kwezinto zensimbi zendabuko zamatafula okusebenza okusika nge-laser asebenza kahle kakhulu.

1. Ukuzinza Kokushisa: Ukunqoba Inselele Yokushisa

Ukusikwa nge-laser, ngokwemvelo yako, kukhiqiza ukushisa. Amatafula okusebenza ensimbi—ngokuvamile insimbi noma insimbi ephonswe ngensimbi—ahlushwa yi-coefficient ephezulu yokwanda kokushisa (i-CTE). Njengoba izinga lokushisa lishintshashintsha, insimbi iyakhula futhi inciphe kakhulu, okuholela ekushintsheni kobukhulu bezinga le-micron kulo lonke ubuso betafula. Lokhu kukhukhuleka kokushisa kuhumusha ngokuqondile ezindleleni zokusika ezinganembile, ikakhulukazi ngezikhathi ezinde noma emishinini emikhulu.

Ngokuphambene nalokho, i-Black Granite ye-ZHHIMG® ine-CTE ephansi kakhulu. Le nto iyakwazi ukumelana nokushintsha kwezinga lokushisa, okuqinisekisa ukuthi ubukhulu bejometri obubalulekile betafula lokusebenza buhlala buzinzile ngisho nangesikhathi sokusebenza okukhulu, isikhathi eside. Lokhu kungapheli kokushisa kubalulekile ekugcineni ukunemba kwezinga le-nanometer okudingeka yi-laser optics yesimanje.

2. Ukudambisa Ukudlidliza: Ukufinyelela Ukulawulwa Okuphelele Kwemisebe

Ukusika nge-laser, ikakhulukazi izinhlelo ze-laser ezisheshayo noma eziqhutshwa yi-pulsed, kudala amandla ashukumisayo kanye nokudlidliza. Insimbi iyazwakala, ikhulisa lokhu kudlidliza futhi ibangele ukujikijela okuncane ohlelweni, okungafiphaza indawo ye-laser futhi kwehlise ikhwalithi yokusikwa.

Isakhiwo se-granite ephezulu ye-ZHHIMG® (efika ku-≈3100 kg/m3) sifanelekile ngokwemvelo ekucindezelweni kokudlidliza okuphezulu. I-granite imunca amandla omshini ngokwemvelo futhi iwachithe ngokushesha. Lesi sisekelo esithule nesizinzile siqinisekisa ukuthi ama-optics agxile ku-laser athambile kanye nama-motor aqondile asheshayo asebenza endaweni engenazo izidlidliza, egcina ukunemba kokubekwa kwe-beam kanye nobuqotho bomphetho osikiwe.

3. Ubuqotho Bezinto Ezibonakalayo: Aziboli Futhi Azinamagnetic

Ngokungafani nensimbi, i-granite ayiboli. Ayinazo izinto ezipholisa umoya, uketshezi olusikiwe, kanye nomswakama womoya ovamile ezindaweni zokukhiqiza, okuqinisekisa ukuthi isikhathi eside setafula lokusebenza kanye nobuqotho bejometri kuhlala kuphelele ngaphandle kwengozi yokugqwala noma ukuwohloka kwezinto.

Ngaphezu kwalokho, ngemishini ehlanganisa ubuchwepheshe be-magnetic sensing obuzwela kakhulu noma ubuchwepheshe be-linear motor, i-granite ayisebenzi ku-magnetic. Lokhu kususa ingozi yokuphazamiseka kwe-electromagnetic (EMI) okungalethwa yizisekelo zensimbi, okuvumela izinhlelo zokubeka eziyinkimbinkimbi ukuthi zisebenze kahle.

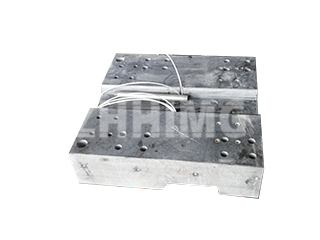

4. Amandla Okucubungula: Ukwakha Okukhulu Nokuqondile

Amandla okukhiqiza angenakuqhathaniswa e-ZHHIMG® asusa imikhawulo yosayizi evame ukuhlupha amatafula asekelwe ensimbi. Singochwepheshe ekukhiqizeni amatafula e-granite e-monolithic eyodwa afinyelela kumamitha angu-20 ubude kanye namathani ayi-100 ngesisindo, acwebezelisiwe abe yi-nanometer flat yizingcweti zethu ezingochwepheshe. Lokhu kuvumela abakhi bemishini ye-laser ukuthi bakhe izicucu zefomethi ezinkulu kakhulu ezigcina ubuqotho be-single piece kanye nokunemba okukhulu kuyo yonke imvilophu yabo yokusebenza—into engenakwenzeka ngezinsimbi ezihlanganisiwe noma eziboshwe ngebholidi.

Kubakhiqizi bezinhlelo zokusika i-laser ezisezingeni lomhlaba, ukukhetha kusobala: ukuzinza kokushisa okungenakuqhathaniswa, ukudambisa ukudlidliza, kanye nokunemba kwe-monolithic kwe-ZHHIMG® Granite Worktable kunikeza isisekelo esiphezulu sejubane nokunemba, okuguqula izinselele zezinga le-micron zibe imiphumela ejwayelekile.

Isikhathi sokuthunyelwe: Okthoba-09-2025