Ubuqotho banoma yikuphi ukukhiqizwa okunembile noma inqubo ye-metrology buqala ngesisekelo sayo. Kwa-ZHHIMG®, yize idumela lethu lakhiwe ngezixazululo ze-Ultra-Precision Granite, siyaqaphela indima ebalulekile edlalwa yi-Cast Iron Surface Plates kanye ne-Marking Plates kuzo zonke izimboni zomhlaba. Ukuqonda ukuthi ungawafaka kanjani, uwalondoloze, futhi uwaqinisekise kanjani ukunemba kwala mathuluzi okubhekisela akuyona nje indlela engcono kakhulu—umehluko phakathi kokuqinisekiswa kwekhwalithi kanye nokungcola okubizayo.

Imfuneko Ephelele: Ukufakwa Okufanelekile kanye Nesakhiwo Esingenazinkinga

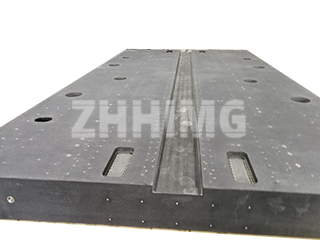

Ngaphambi kokuba ipuleti lokumaka lensimbi elenziwe ngensimbi likwazi ukuletha ukunemba kwalo kokubhekisela, kumele lifakwe futhi lilungiswe kahle. Lesi sigaba esibalulekile sokusetha asigcini nje ngenqubo; sithinta ngqo ubuqotho besakhiwo sepuleti kanye nokuba yisicaba. Ukufakwa okungalungile—njengokusatshalaliswa komthwalo okungalingani noma ukuleveli okungalungile—kungephula imithetho yemboni futhi kuphazamise unomphela ipuleti, okwenza lingasetshenziswa. Ngakho-ke, abasebenzi abagunyaziwe nabaqeqeshiwe kuphela okufanele benze lo msebenzi. Ukwephula lezi zinqubo akugcini nje ngokungalandeli imithetho kodwa futhi kungalimaza isakhiwo sethuluzi lokunemba.

Amapuleti Okumaka Ekuhambeni Komsebenzi: Idatha Yokubhekisela

Kunoma iyiphi indawo yokusebenzela, amathuluzi ahlukaniswa ngezindima ezithile: ireferensi, ukulinganisa, ukudweba okuqondile, kanye nokubopha. Ipuleti lokumaka liyithuluzi eliyisisekelo lereferensi lenqubo yokubhala. Ukubhala ngokwako kuwumsebenzi obalulekile wokuhumusha imininingwane yokudweba ibe yinto yokusebenza engenalutho noma engaqediwe ngokuphelele, kusungulwe imingcele ecacile yokucubungula, amaphuzu okubhekisela, kanye nemigqa yokulungisa ebalulekile. Lokhu kunemba kokuqala kokubhala, okuvame ukudingeka kube phakathi kuka-0.25 mm kuya ku-0.5mm, kunomthelela oqondile nojulile kwikhwalithi yomkhiqizo wokugcina.

Ukuze kulondolozwe lobu buqotho, ipuleti kumele lilinganiswe futhi libekwe ngokuphephile, umthwalo usatshalaliswe ngokulinganayo kuzo zonke izindawo zokusekela ukuze kuvinjelwe ukucindezeleka kwesakhiwo. Abasebenzisi kumele baqinisekise ukuthi isisindo somsebenzi asidluli umthwalo olinganiselwe wepuleti ukuze kuvinjelwe umonakalo wesakhiwo, ukuguquguquka, kanye nokwehla kwekhwalithi yokusebenza. Ngaphezu kwalokho, indawo yokusebenza kufanele isetshenziswe ngokufanayo ukuvimbela ukuguguleka nokuqhekeka kwendawo, ukuqinisekisa ukuthi ihlala isikhathi eside.

Ukuhlola Ukuthamba: Isayensi Yokuqinisekisa

Indlela yokulinganisa yangempela yepuleti lokubhala ukuthi indawo yalo yokusebenza ithambile kangakanani. Indlela eyinhloko yokuqinisekisa i-Spot Method. Le ndlela inquma ubuningi obudingekayo bezindawo zokuxhumana ngaphakathi kwendawo yesikwele engu-25mm:

- Amapuleti ebanga 0 kanye nele-1: Okungenani izindawo ezingu-25.

- Amapuleti ebanga lesi-2: Okungenani izindawo ezingama-20.

- Amapuleti ebanga lesi-3: Okungenani izindawo eziyi-12.

Nakuba inqubo yendabuko "yokuklwebha amapuleti amabili komunye nomunye" ingaqinisekisa ukulingana okuqinile kanye nokusondelana komphezulu, ayiqinisekisi ukuba yisicaba. Le ndlela ingaholela ezindaweni ezimbili ezihlangana kahle empeleni, ezigobile ngendlela eyindilinga. Ukuqonda kwangempela kanye nokuba yisicaba kumele kuqinisekiswe kusetshenziswa izindlela eziqinile. Ukuphambuka kokuqonda kungalinganiswa ngokuhambisa inkomba yokudayela kanye nokuma kwayo eceleni kwereferensi eqondile eyaziwayo, njengombusi we-engeli eqondile, ngaphesheya kobuso bepuleti. Kumapuleti okulinganisa adinga kakhulu, i-Optical Plane Method esebenzisa i-optical interferometry isetshenziswa ukuqinisekisa ukunemba ezingeni le-sub-micron.

Ukuphathwa Kwamaphutha Ngokuphelele: Ukuqinisekisa Ukuphila Isikhathi Eside Nokuthobela Imithetho

Ikhwalithi yepuleti lokumaka ilawulwa yizinhlaka zomthetho eziqinile, njengendinganiso ye-JB/T 7974—2000 embonini yemishini. Ngesikhathi senqubo yokuphonsa, kungenzeka kube neziphazamiso ezifana nokubhoboka, imigodi yesihlabathi, kanye nemigodi yokuncibilika. Ukuphathwa kahle kwalezi ziphazamiso zokuphonsa ezingokwemvelo kubalulekile empilweni yesevisi yepuleti. Kumapuleti anezinga lokunemba elingaphansi kuka-“00,” ukulungiswa okuthile kuvunyelwe:

- Amaphutha amancane (izinhlayiya zesihlabathi ezinobubanzi obungaphansi kuka-15mm) zingaxhunywa ngento efanayo, uma nje ubulukhuni bepulagi buphansi kunensimbi ezungezile.

- Indawo yokusebenza akufanele ibe nezindawo zokuxhuma ezingaphezu kwezine, ezihlukaniswe yibanga okungenani elingu-$80\text{mm}$.

Ngaphandle kokwenza amaphutha, indawo yokusebenza kumele ingabi nokugqwala, imihuzuko, noma ukufiphala okungathinti ukusetshenziswa.

Ukugcinwa Kokunemba Okuhlala Njalo

Kungakhathaliseki ukuthi ithuluzi lokubhekisela liyi-Cast Iron Marking Plate noma i-ZHHIMG® Granite Surface Plate, ukulungiswa kulula kodwa kubalulekile. Indawo engaphezulu kumele igcinwe ihlanzekile; uma ingasetshenziswa, kufanele ihlanzwe kahle futhi imbozwe ngamafutha okuvikela ukuvimbela ukugqwala futhi imbozwe ngesembozo esivikelayo. Ukusetshenziswa kufanele kwenziwe njalo endaweni elawulwayo, okungcono kakhulu ekushiseni okumaphakathi okungu-(20±5)℃, futhi ukudlidliza kumele kugwenywe ngokuqinile. Ngokunamathela kulezi ziqondiso eziqinile zokufakwa, ukusetshenziswa, kanye nokugcinwa, abakhiqizi bangaqinisekisa ukuthi izinkomba zabo zihlala zinembile, zivikela ikhwalithi kanye nobuqotho bemikhiqizo yabo yokugcina.

Isikhathi sokuthunyelwe: Okthoba-31-2025