Emkhakheni wokukhiqiza ama-semiconductor, ukunemba kwemishini yokuhlola ama-wafer kunquma ngqo ikhwalithi kanye nokukhiqiza kwama-chips. Njengesisekelo esisekela izingxenye zokutholwa okuyinhloko, ukuzinza kobukhulu bezinto eziyisisekelo zemishini kudlala indima ebalulekile ekusebenzeni kwesikhathi eside kwemishini. I-Granite kanye ne-cast iron kuyizinto ezimbili eziyisisekelo ezisetshenziswa kakhulu zemishini yokuhlola ama-wafer. Ucwaningo lokuqhathanisa lweminyaka eyi-10 luveze umehluko omkhulu phakathi kwazo maqondana nokuzinza kobukhulu, lunikeza izinkomba ezibalulekile zokukhetha imishini.

Isizinda Sokuhlola Nokuklama

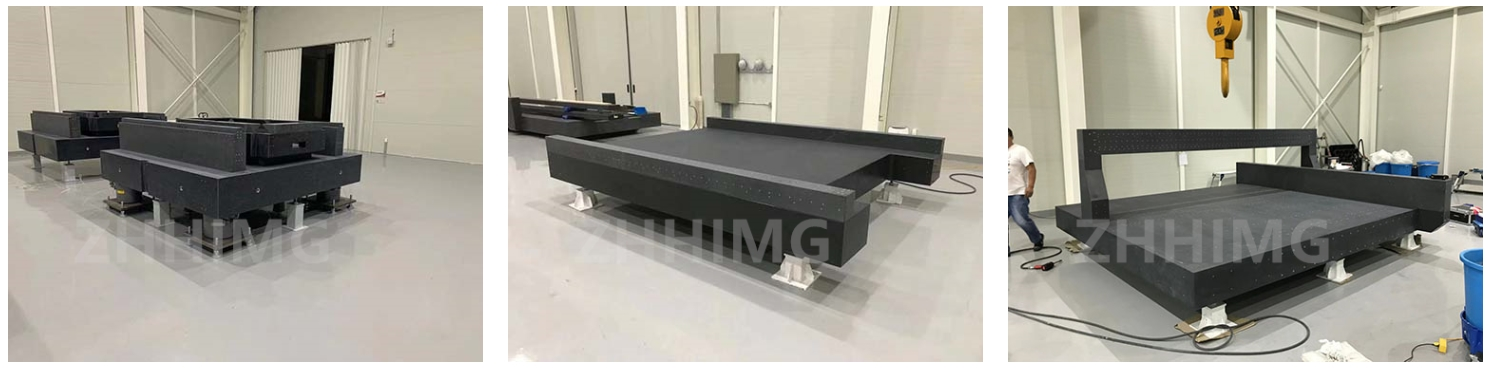

Inqubo yokukhiqiza ama-wafer e-semiconductor inezidingo eziphakeme kakhulu zokunemba kokutholwa. Ngisho nokuphambuka kobukhulu bezinga le-micrometer kungaholela ekwehleni kokusebenza kwe-chip noma ngisho nokuklwebheka. Ukuze kuhlolwe ukuzinza kobukhulu be-granite ne-cast iron ngesikhathi sokusetshenziswa kwesikhathi eside, ithimba locwaningo laklama izivivinyo ezilingisa izindawo zokusebenza zangempela. Amasampula e-granite ne-cast iron anencazelo efanayo akhethiwe futhi abekwa ekamelweni lezemvelo lapho izinga lokushisa lalishintshashintsha khona kusukela ku-15℃ kuya ku-35℃ kanti umswakama wawushintshashintsha kusukela ku-30% kuya ku-70% RH. Ukudlidliza komshini ngesikhathi sokusebenza kwemishini kwakulingiswa ngetafula lokudlidliza. Ubukhulu obubalulekile bamasampula babulinganiswa njalo ngekota kusetshenziswa i-interferometer ye-laser enembayo ephezulu, futhi idatha yaqoshwa ngokuqhubekayo iminyaka eyi-10.

Umphumela wokuhlola: Inzuzo ephelele ye-granite

Iminyaka eyishumi yedatha yokuhlola ikhombisa ukuthi i-substrate ye-granite ibonisa ukuzinza okumangalisayo. I-coefficient yayo yokwanda kokushisa iphansi kakhulu, isilinganiso sayo singu-4.6 × 10⁻⁶/℃ kuphela. Ngaphansi kwezinguquko ezinkulu zokushisa, ukuphambuka kobukhulu kuhlala kulawulwa ngaphakathi kuka-±0.001mm. Uma ubhekene nezinguquko zomswakama, isakhiwo esiminyene se-granite senza ukuthi ingathinteki, futhi akukho zinguquko zobukhulu ezilinganiswayo ezenzekayo. Endaweni yokudlidliza komshini, izici ezinhle kakhulu zokudambisa ze-granite zimunca ngempumelelo amandla okudlidliza, futhi ukuguquguquka kobukhulu kuncane kakhulu.

Ngokuphambene nalokho, kwi-substrate yensimbi ephonswe ngensimbi, isilinganiso sayo esimaphakathi sokwanda kokushisa sifinyelela ku-11×10⁻⁶/℃ - 13×10⁻⁶/℃, kanti ukuphambuka okuphezulu okubangelwa ukushintsha kwezinga lokushisa kungakapheli iminyaka eyi-10 kungu-±0.05mm. Endaweni enomswakama, insimbi ephonswe ngensimbi ithambekele ekugqwaleni nasekugqwaleni. Amanye amasampula abonisa ukuphambuka kwendawo, futhi ukuphambuka kobukhulu kuyanda kakhulu. Ngaphansi kwesenzo sokudlidliza komshini, insimbi ephonswe ngensimbi inokusebenza okungekuhle kokudlidliza futhi usayizi wayo uyashintshashintsha njalo, okwenza kube nzima ukuhlangabezana nezidingo zokunemba okuphezulu zokuhlolwa kwe-wafer.

Isizathu esibalulekile somehluko ekuzinzeni

I-granite yakhiwa eminyakeni engamakhulu ezigidi ngezinqubo ze-geological. Isakhiwo sayo sangaphakathi siminyene futhi sifana, futhi amakristalu amaminerali ahlelwe kahle, asusa ukucindezeleka kwangaphakathi ngokwemvelo. Lokhu kwenza ukuthi ingazweli kakhulu ezinguqukweni zezinto zangaphandle njengokushisa, umswakama kanye nokudlidliza. Insimbi ephothiwe yenziwa ngenqubo yokukhipha futhi ineziphambeko ezincane njengemibhobho kanye nemigodi yesihlabathi ngaphakathi. Okwamanje, ukucindezeleka okusele okudalwe ngesikhathi senqubo yokukhipha kungabangela izinguquko zobukhulu ngaphansi kokukhuthazwa kwendawo yangaphandle. Izakhiwo zensimbi zensimbi ephothiwe zenza kube lula ukugqwala ngenxa yomswakama, kusheshiswe umonakalo wesakhiwo futhi kuncishiswe ukuzinza kobukhulu.

Umthelela emishinini yokuhlola i-wafer

Imishini yokuhlola i-wafer esekelwe ku-granite substrate, ngokusebenza kwayo okuzinzile kobukhulu, ingaqinisekisa ukuthi uhlelo lokuhlola lugcina ukunemba okuphezulu isikhathi eside, lunciphise ukwahlulela okungalungile kanye nokungatholakali okubangelwa ukuzulazula kokunemba kwemishini, futhi luthuthukise kakhulu isivuno somkhiqizo. Okwamanje, izidingo zokulungisa eziphansi zinciphisa izindleko zomjikelezo wokuphila kwemishini. Imishini esebenzisa i-cast iron substrates, ngenxa yokuzinza kobukhulu obubi, idinga ukulinganiswa nokugcinwa njalo. Lokhu akugcini nje ngokwandisa izindleko zokusebenza kodwa futhi kungathinta ikhwalithi yokukhiqizwa kwe-semiconductor ngenxa yokunemba okunganele, okubangela ukulahlekelwa kwezomnotho okungenzeka.

Ngaphansi komkhuba wokufuna kwemboni ye-semiconductor ukunemba okuphezulu kanye nekhwalithi engcono, ukukhetha i-granite njengesisekelo semishini yokuhlola i-wafer ngokungangabazeki kuyisinyathelo esihlakaniphile sokuqinisekisa ukusebenza kwemishini nokuthuthukisa ukuncintisana kwamabhizinisi.

Isikhathi sokuthunyelwe: Meyi-14-2025