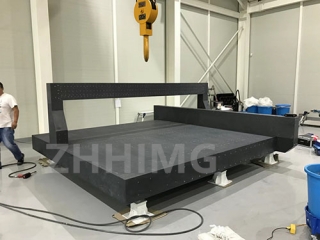

Ekukhiqizweni kwe-Coordinate Measuring Machines (CMM), i-granite ivame ukusetshenziswa ngenxa yokuqina kwayo, ukuqina kwayo, kanye nokunemba kwayo. Uma kukhulunywa ngokukhiqiza izingxenye ze-granite ze-CMM, izindlela ezimbili zingathathwa: ukwenza ngokwezifiso kanye nokulinganisa. Zombili izindlela zinezinzuzo kanye nokungalungi kwazo okumele kucatshangelwe ukuze kukhiqizwe kahle.

Ukwenza ngokwezifiso kubhekisela ekudalweni kwezingcezu ezihlukile ngokusekelwe ezidingweni ezithile. Kungase kuhilele ukusika, ukupholisha, kanye nokwakheka kwezingxenye zegranite ukuze zivumelane nomklamo othile we-CMM. Enye yezinzuzo ezibalulekile zokwenza ngokwezifiso izingxenye zegranite ukuthi ivumela imiklamo ye-CMM eguquguqukayo futhi elungiselelwe kahle engahlangabezana nezidingo ezithile. Ukwenza ngokwezifiso kungaba futhi ukukhetha okuhle kakhulu lapho kukhiqizwa i-prototype CMM ukuqinisekisa ukwakheka komkhiqizo kanye nokusebenza kwawo.

Enye inzuzo yokwenza ngokwezifiso ukuthi ingahambisana nezintandokazi zamakhasimende ezithile, njengombala, ukuthungwa, nosayizi. Ubuhle obuphezulu bungatholakala ngokuhlanganiswa kobuciko kwemibala ehlukene yamatshe namaphethini ukuthuthukisa ukubukeka kanye nokukhanga kwe-CMM iyonke.

Kodwa-ke, kukhona futhi nokungalungi okuthile ekwenzeni ngokwezifiso izingxenye ze-granite. Okokuqala nokubaluleke kakhulu isikhathi sokukhiqiza. Njengoba ukwenza ngokwezifiso kudinga ukulinganisa okunembile, ukusika, kanye nokubumba, kuthatha isikhathi eside ukuqedela kunezingxenye ze-granite ezijwayelekile. Ukwenza ngokwezifiso kudinga nezinga eliphezulu lobuchwepheshe, okungase kunciphise ukutholakala kwayo. Ngaphezu kwalokho, ukwenza ngokwezifiso kungabiza kakhulu kunokumisa ngokwejwayelekile ngenxa yomklamo wayo oyingqayizivele kanye nezindleko ezengeziwe zomsebenzi.

Ngakolunye uhlangothi, ukulinganisa kubhekisela ekukhiqizweni kwezingxenye ze-granite ngobukhulu obujwayelekile kanye nezimo ezingasetshenziswa kunoma iyiphi imodeli ye-CMM. Kuhilela ukusetshenziswa kwemishini ye-CNC enembile kanye nezindlela zokukhiqiza ukukhiqiza izingxenye ze-granite ezisezingeni eliphezulu ngezindleko eziphansi. Njengoba ukulinganisa kungadingi imiklamo noma ukwenza ngokwezifiso okuhlukile, kungaqedwa ngokushesha okukhulu, futhi izindleko zokukhiqiza ziphansi. Le ndlela isiza ukunciphisa isikhathi sokukhiqiza sonke futhi ingathinta nezikhathi zokuthumela nezokuphatha.

Ukumiswa kwesakhiwo kungaphinde kuholele ekuqineni nasekuqineni kwezingxenye okungcono. Njengoba izingxenye zegranite ezimisiwe zikhiqizwa emthonjeni owodwa, zingakopishwa ngokunemba okuthembekile. Ukumiswa kwesakhiwo kuvumela nokugcinwa nokulungiswa okulula njengoba izingxenye zingashintshaniswa kalula.

Kodwa-ke, ukwenziwa kwe-standardization kunezinkinga zako. Kunganciphisa ukuguquguquka komklamo, futhi kungase kungahlangabezani nezidingo ezithile zomklamo njalo. Kungase futhi kubangele ukukhanga okulinganiselwe kobuhle, njengokufana kombala wamatshe kanye nokuthungwa kwawo. Ngaphezu kwalokho, inqubo yokwenziwa kwe-standardization ingabangela ukulahlekelwa okuthile kokunemba uma kuqhathaniswa nezingxenye ezenziwe ngokwezifiso ezikhiqizwe amasu obuciko anemininingwane eminingi.

Ekuphetheni, kokubili ukwenza ngokwezifiso kanye nokulinganisa izingxenye ze-granite kunezinzuzo kanye nokungalungi kwazo uma kukhulunywa ngokukhiqizwa kwe-CMM. Ukwenza ngokwezifiso kunikeza imiklamo efanelekile, ukuguquguquka, kanye nobuhle obuphezulu kodwa kuza nezindleko eziphakeme kanye nezikhathi zokukhiqiza ezinde. Ukwenza ngokwezifiso kunikeza ikhwalithi ehambisanayo, isivinini, kanye nezindleko zokukhiqiza eziphansi kodwa kunciphisa ukuguquguquka komklamo kanye nokuhlukahluka kobuhle. Ekugcineni, kuxhomeke kumkhiqizi we-CMM kanye nomsebenzisi wokugcina ukuthi banqume ukuthi iyiphi indlela efanelana kahle nezidingo zabo zokukhiqiza kanye nemininingwane ehlukile.

Isikhathi sokuthunyelwe: Ephreli-11-2024