Ukuthungwa kwamaminerali, okwaziwa nangokuthi ukuthungwa kwe-granite, sekuthole ukuthandwa embonini yokukhiqiza ngenxa yokusebenza kwayo okuphezulu kokumuncwa kokushaqeka uma kuqhathaniswa nensimbi esetshenziswayo. Le nzuzo idlala indima ebalulekile ekuthuthukiseni ukunemba komshini kanye nekhwalithi yobuso bamathuluzi omshini.

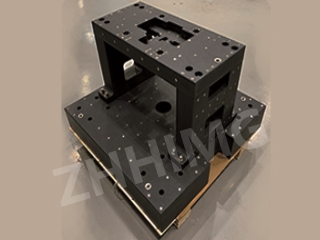

I-Granite, uhlobo lokuphonswa kwamaminerali, inikeza izakhiwo ezimangalisayo zokumunca ukushaqeka. Uma kuqhathaniswa nensimbi ephonswayo yendabuko, i-granite inamandla aphezulu okudambisa, okusho ukuthi ingamunca ngempumelelo ukudlidliza kanye nokushaqeka okubangelwa yinqubo yomshini. Lokhu kuwusizo kakhulu ekusebenzeni kwe-lathes, lapho ukunemba nokuzinza kubaluleke kakhulu.

Ukusebenza okuphezulu kokumuncwa kokushaqeka kwe-lathe yokugaya amaminerali kunciphisa kakhulu ukudluliselwa kokudlidliza esakhiweni somshini. Ngenxa yalokho, i-lathe ihlangabezana nokuphambuka okuncane kanye nokuguquguquka ngesikhathi sokusebenza, okuholela ekuqineni kokunemba komshini. Ukuqina okunikezwa yi-granite casting kuqinisekisa ukuthi amathuluzi okusika agcina ukuxhumana okuhambisanayo ne-workpiece, okuholela ekususweni kwezinto eziqondile nezifanayo.

Ngaphezu kwalokho, ukudlidliza okuncishisiwe kanye nokuzinza okuthuthukisiwe okunikezwa ukuphonswa kwamaminerali kunegalelo ekhwalithini ephezulu yobuso bezingxenye ezifakwe umshini. Ngokudlidliza okuncane okubangelwa umshini, amathuba okungahambi kahle kobuso, njengezimpawu zokukhuluma kanye nezimpawu zamathuluzi, ancishiswa kakhulu. Lokhu kuphumela ekuqedweni kobuso okubushelelezi kanye nemininingwane emihle kakhulu ku-workpiece, okuhlangabezana nezidingo zekhwalithi eqinile yezinqubo zokukhiqiza zanamuhla.

Ngaphezu kwamakhono ayo okumunca ukushaqeka, ukuthungwa kwamaminerali nakho kukhombisa ukuzinza okuhle kakhulu kokushisa kanye nokumelana nezimo zemvelo, okuqhubeka nokufaka isandla ekuqondeni nasekuthembekeni kwamathuluzi omshini.

Ekuphetheni, izinzuzo ze-lathe yokugaya amaminerali, ikakhulukazi ukusebenza kwayo okuphezulu kokumuncwa kokushaqeka, zidlala indima ebalulekile ekuthuthukiseni ukunemba komshini kanye nekhwalithi yobuso. Ngokunciphisa ukudlidliza nokuqinisekisa ukuzinza, ukugaya i-granite kuvumela abakhiqizi ukuthi bafinyelele ukunemba okuphezulu, ukuqedwa kobuso okuthuthukisiwe, futhi ekugcineni, imikhiqizo yekhwalithi ephezulu. Njengoba isidingo somshini wokugaya okunemba okuphezulu siqhubeka nokukhula, ukwamukelwa kobuchwepheshe bokugaya amaminerali kulungele ukwenza umthelela omkhulu ekusaseni lokukhiqizwa kwamathuluzi omshini.

Isikhathi sokuthunyelwe: Septhemba-06-2024