Izingxenye ze-granite eqondile ziyithuluzi elibalulekile embonini yokukhiqiza, yokuhlola, kanye ne-metrology. Zihlinzeka ngobuso obuyisicaba, obuzinzile, nobunembile lapho kungalinganiswa khona. I-granite iyinto efanelekile yezingxenye eziqondile ngenxa yokuqina kwayo, ukuminyana, kanye ne-coefficient ephansi yokwanda kokushisa.

Kunezinhlobo ezahlukene zezingxenye ze-precision granite ezisetshenziswa ezinhlotsheni ezahlukene zokusebenza, kuye ngokuthi zicacisiwe yini kanye nezidingo zazo. Ezinye zezinhlobo ezivame kakhulu zezingxenye ze-precision granite yilezi:

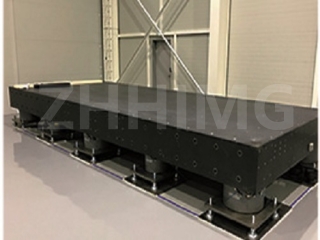

1. Amapuleti Omphezulu – Amapuleti omphezulu makhulu, ayisicaba enziwe nge-granite. Ngokuvamile afika ngobukhulu obusukela kumasentimitha ambalwa kuya kwamamitha amaningana ubude nobubanzi. Asetshenziswa njengendawo yokubhekisela yokuhlola, ukuhlola, kanye nokulinganisa amathuluzi nezingxenye ezahlukahlukene. Amapuleti omphezulu angaba namazinga ahlukene okunemba, kusukela ku-Grade A, okuyiwona aphezulu kakhulu, kuya ku-Grade C, okuyiwona aphansi kakhulu.

2. Izikwele Zegranite – Izikwele Zegranite zingamathuluzi okugaya nokuhlola ngokunemba asetshenziselwa ukuhlola ubungako bezingxenye, kanye nokusetha imishini yokugaya kanye nama-grinder angaphezulu. Ziza ngobukhulu obuhlukahlukene, kusukela kusikwele esincane esingu-2x2-intshi kuya kusikwele esikhulu esingu-6x6-intshi.

3. Ukufana Kwegranite – Ukufana Kwegranite kuyizitini eziqondile ezisetshenziselwa ukuvumelanisa izinto zokusebenza emishinini yokugaya, imishini yokugaya, kanye nemishini yokugaya. Zitholakala ngobude nobubanzi obuhlukahlukene, kanti ukuphakama kuyafana kuzo zonke izitini ezisesethini.

4. Amabhulokhi e-V e-Granite – Amabhulokhi e-V e-Granite asetshenziselwa ukubamba izinto zokusebenza ezimise okwesilinda zokubhoboza noma ukugaya. Umsele onobunjwa obufana no-V emabhulokhi usiza ekugxiliseni ingxenye yokusebenza ukuze kwenziwe imishini enembile.

5. Amapuleti E-engeli E-Granite – Amapuleti e-engeli e-granite angamathuluzi okunemba asetshenziselwa ukuhlelwa, ukuhlolwa, kanye nokulungiswa kwezingxenye. Ngokuvamile akhiqizwa ngokwezincazelo eziqinile, ngama-engeli asukela ku-0 kuya ku-90 degrees.

6. Amabhulokhi Okuphakamisa I-Granite – Amabhulokhi okuphakamisa i-granite asetshenziselwa ukwandisa ukuphakama kwamapuleti angaphezulu, amapuleti e-engeli, namanye amathuluzi okunemba. Asetshenziselwa ukuphakamisa izinto zokusebenza zifinyelele ukuphakama okukhululekile ukuze zihlolwe futhi zisebenze.

Ngaphezu kwezinhlobo ezahlukene zezingxenye ze-precision granite, kunezincazelo ezahlukene kanye namabanga asetshenziswa ukunquma ukunemba kanye nekhwalithi yazo. Ukunemba kwengxenye ye-precision granite kuvame ukulinganiswa ngama-micron, okuyiyunithi yokulinganisa elingana nengxenye eyodwa kweziyinkulungwane yemilimitha.

Izinga lengxenye ye-granite enembile libhekisela ezingeni layo lokunemba. Kunezinhlobo eziningana zezingxenye ze-granite enembile, lapho iBanga A liphezulu kakhulu kanti iBanga C liphansi kakhulu. Izinga lengxenye ye-granite enembile linqunywa ubucaba bayo, ukulingana kanye nokuphela kobuso.

Ekuphetheni, izingxenye ze-precision granite zingamathuluzi abalulekile embonini yokukhiqiza, yokuhlola, kanye ne-metrology. Kunezinhlobo ezahlukene zezingxenye ze-precision granite ezisetshenziselwa izinhlelo zokusebenza ezahlukahlukene, futhi ziza ngezincazelo namazinga ahlukene ukuqinisekisa ukuthi zihlangabezana nezidingo zokunemba, ukuzinza, kanye nekhwalithi yomkhakha.

Isikhathi sokuthunyelwe: Feb-23-2024