I-Granite iyinto ethandwayo esetshenziselwa imishini yokubhoboza neyokugaya i-PCB. Yaziwa ngobulukhuni bayo, ukuqina kwayo, kanye nokumelana nokuguguleka okukhulu. Kodwa njenganoma iyiphi into, i-granite nayo inezinkinga zayo, ikakhulukazi uma isetshenziswa emishinini yokubhoboza neyokugaya i-PCB. Kulesi sihloko, sizoxoxa ngezinkinga zokusebenzisa izakhi ze-granite emishinini yokubhoboza neyokugaya i-PCB.

1. Izindleko

Enye yezinto ezimbi kakhulu zokusebenzisa izakhi ze-granite emishinini yokubhoboza neyokugaya ye-PCB yizindleko. I-granite iyinto ebiza kakhulu, okusho ukuthi izindleko zokukhiqiza imishini yokubhoboza neyokugaya ye-PCB kusetshenziswa i-granite zizoba phezulu kakhulu kunezinye izinto. Lokhu kungenza imishini ibize kakhulu, okwenza kube nzima ngamabhizinisi ukutshala imali kuyo.

2. Isisindo

Enye inkinga yokusebenzisa izakhi ze-granite emishinini yokubhoboza neyokugaya ye-PCB isisindo. I-granite iyinto eqinile futhi esindayo, okwenza imishini ibe nzima futhi kube nzima ukuyihambisa. Lokhu kungaba yinkinga emabhizinisini adinga ukuhambisa imishini ezindaweni ezahlukene.

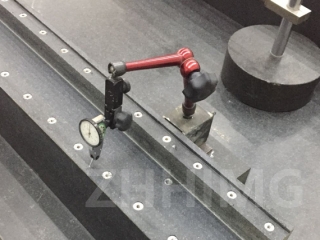

3. Ukudlidliza

I-Granite iyinto enhle kakhulu yokunciphisa ukudlidliza, kodwa ingabangela nokudlidliza emshinini ngokwawo. Lokhu kudlidliza kungabangela amaphutha enkambisweni yokusika, okuholela ekusikeni okunganembile kanye nemigodi. Lokhu kungabangela imikhiqizo esezingeni eliphansi kanye nesidingo sokusebenza kabusha, okungagcina kwandise izindleko nesikhathi esidingekayo ekukhiqizeni.

4. Ukulungiswa

Ukugcina izakhi ze-granite emishinini yokubhoboza neyokugaya ye-PCB kungaba nzima kakhulu kunezinye izinto ezifana ne-aluminium. Izindawo ze-granite zidinga ukuhlanzwa nokupholishwa njalo ukuze zigcine ukuqeda kwazo kanye nokumelana nokuguguleka. Lokhu kungadla isikhathi futhi kubize kakhulu, ikakhulukazi uma imishini isetshenziswa njalo.

5. Umshini

I-Granite iyinto eqinile futhi ebanzi, okwenza kube nzima ukuyisebenzisa ngomshini. Lokhu kunganezela ezindlekweni zokukhiqiza imishini yokubhoboza neyokugaya i-PCB kusetshenziswa i-granite, njengoba kungadingeka imishini ekhethekile namathuluzi ukuze kusikwe futhi kulolongwe impahla. Lokhu kunganezela ezindlekweni zokulungisa, njengoba imishini namathuluzi asetshenziselwa ukukhanda i-granite kungadinga ukushintshwa njalo.

Ekuphetheni, yize i-granite iyinto enhle kakhulu yemishini yokubhoboza neyokugaya i-PCB ngokuya ngobulukhuni bayo, ukuqina, kanye nokumelana nokuguguleka, nayo inezinkinga zayo. Lokhu kufaka phakathi izindleko eziphakeme, isisindo, ukudlidliza, ukunakekelwa, kanye nobunzima bokusebenza ngomshini. Kodwa-ke, ngokunakekelwa nokugcinwa okufanele, izinzuzo zokusebenzisa izakhi ze-granite emishinini yokubhoboza neyokugaya i-PCB zingadlula izinkinga zayo.

Isikhathi sokuthunyelwe: Mashi-15-2024