Emkhakheni wokukhiqiza ngokunemba, izingxenye ze-granite zimi njengamaqhawe angakadunyiswa asekela ukunemba kwemishini ethuthukisiwe. Kusukela emigqeni yokukhiqiza ye-semiconductor kuya kumalebhu e-metrology asezingeni eliphezulu, lezi zakhiwo zamatshe ezikhethekile zinikeza isisekelo esiqinile esidingekayo sokulinganisa i-nanoscale kanye nokusebenza okunembile kakhulu. Kwa-ZHHIMG, sichithe amashumi eminyaka sithuthukisa ubuciko nesayensi yokuklama izingxenye ze-granite, sihlanganisa ubuciko bendabuko nezimiso zobunjiniyela besimanje ukuze sakhe izixazululo ezihlangabezana nezindinganiso zezimboni ezidinga kakhulu.

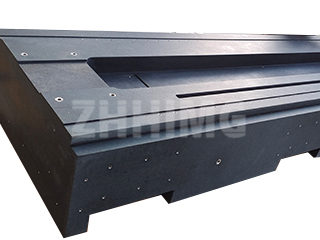

Uhambo lokudala izingxenye ze-granite ezisebenza kahle kakhulu luqala ngokukhethwa kwezinto—isinqumo esibalulekile esithinta ngqo ukusebenza komkhiqizo wokugcina. Onjiniyela bethu basebenzisa kuphela i-granite emnyama ye-ZHHIMG®, into eyimfihlo enobuningi obungaba ngu-3100 kg/m³ edlula izinhlobo eziningi ze-granite zaseYurophu naseMelika kokubili ekuzinzeni nasezimpahleni zomzimba. Lesi sakhiwo esiminyene asigcini nje ngokuhlinzeka ngokudambisa ukudlidliza okungavamile kodwa futhi siqinisekisa ukwanda okuncane kokushisa, isici esibalulekile sokugcina ukunemba ezimweni zemvelo ezahlukahlukene. Ngokungafani nabanye abakhiqizi abasika amakhona besebenzisa izinto ezithatha indawo ze-marble, sihlala sizibophezele kule nto ephakeme eyakha umgogodla wokuthembeka kwezingxenye zethu.

Nokho, ukukhethwa kwezinto kuphela kumane kuyisiqalo. Ubunzima bangempela bomklamo wezingxenye ze-granite bubonakala ekulinganiseni ngokucophelela izidingo zokusebenza namaqiniso emvelo. Yonke idizayini kumele ibhekele ukusebenzisana phakathi kwengxenye nendawo yayo yokusebenza, okuhlanganisa ukuguquguquka kwezinga lokushisa, amazinga omswakama, kanye nemithombo yokudlidliza engaba khona. Indawo yethu yokusebenzela yokulawula izinga lokushisa nomswakama engu-10,000 m² (indawo yokusebenzela yokushisa nomswakama eqhubekayo) yenzelwe ngqo ukubhekana nalezi zinselele, inephansi likakhonkolo eliqinile kakhulu elingu-1000 mm kanye nemisele yokulwa nokudlidliza engu-500 mm ububanzi, engu-2000 mm ejulile edala indawo efanele kokubili yokukhiqiza nokuhlola.

Ukunemba kwemishini kungenye itshe eliyinhloko lomklamo wezingxenye ze-granite ophumelelayo. Ukuhlanganiswa kwezithako zensimbi ku-granite kudinga ukubekezelelana okuqinile ukuqinisekisa ukusatshalaliswa okufanele komthwalo kanye nokudluliselwa kwe-torque. Ithimba lethu lokuklama licabangela ngokucophelela ukuthi izibambo zendabuko zingashintshwa yini ngezinhlelo ezisekelwe ku-groove ezinembile, njalo lihlola ukuhweba phakathi kobuqotho besakhiwo kanye nokwenzeka kokukhiqiza. Izici zomphezulu zidinga ukunakwa okuqinile—ukuthamba kumele kuvame ukugcinwa ngaphakathi kwamazinga e-micrometer, kuyilapho izindawo zokuthwala umoya zidinga amasu okuqeda akhethekile ukuze kufezwe ukushelela okudingekayo kokunyakaza okungenazingxabano.

Mhlawumbe okubaluleke kakhulu, ukwakheka kwengxenye ye-granite yesimanje kumele kubikezele izidingo ezithile zokusetshenziswa kwayo okuhlosiwe. Isisekelo somshini wokuhlola we-semiconductor, isibonelo, sibhekene nezidingo ezihluke kakhulu kunepuleti lobuso lelebhu ye-metrology. Onjiniyela bethu babambisana eduze namakhasimende ukuze baqonde hhayi nje izidingo zobukhulu obusheshayo kodwa futhi nokulindelwe kokusebenza kwesikhathi eside. Le ndlela yokubambisana iholele ezingxenyeni ezikhonza izindima ezibalulekile ekusetshenzisweni kusukela ezinhlelweni ze-laser micromachining kuya emishinini yokulinganisa ethuthukisiwe (ama-CMM).

Inqubo yokukhiqiza ngokwayo imelela ukuhlangana kobuciko bendabuko kanye nobuchwepheshe obusezingeni eliphezulu. Isikhungo sethu sinemishini yokugaya emine yaseTaiwan Nante, ngayinye idlula u-$500,000, ekwazi ukucubungula izinto zokusebenza ezifika ku-6000 mm ubude ngokunemba kwe-sub-micron. Kodwa kanye nale mishini ethuthukisiwe, uzothola ochwepheshe abanolwazi olungaphezu kweminyaka engamashumi amathathu abangafinyelela ukunemba kwe-nanoscale ngokufaka isandla—ikhono esivame ukulibiza ngokuthi “i-artisan metrology.” Lokhu kuhlanganiswa kwezinto ezindala nezintsha kusenza sikwazi ukubhekana ne-geometri yezingxenye eziyinkimbinkimbi kakhulu ngenkathi sigcina amazinga aphezulu okunemba.

Ukuqinisekiswa kwekhwalithi kugcwele kuzo zonke izigaba zenqubo yethu yokuklama nokukhiqiza. Sitshale imali eningi ekudaleni indawo yokulinganisa ephelele ehlanganisa i-German Mahr Dial gauge (izinkomba zokudayela) enesisombululo esingu-0.5 μm, izinhlelo zokulinganisa ze-Mitutoyo coordinate, kanye nama-interferometer e-laser e-Renishaw. Ngayinye yalezi zinsimbi ihlolwa njalo yi-Jinan kanye ne-Shandong Metrology Institutes, okuqinisekisa ukulandelelwa kwezindinganiso zikazwelonke. Lokhu kuzibophezela ekulinganisweni okuhle kuhambisana nefilosofi yethu yenkampani: “Uma ungakwazi ukukulinganisa, awukwazi ukukukhiqiza.”

Ukuzinikela kwethu ekuqondeni nasekukhwalithini kusitholele ubudlelwano nabaholi bemboni emhlabeni wonke, okuhlanganisa i-GE, i-Samsung, ne-Bosch, kanye nezikhungo zocwaningo ezidumile njenge-Singapore National University kanye ne-Stockholm University. Lokhu kubambisana kuqhubeka nokusishukumisela ukuthi sithuthukise izindlela zethu zokuklama futhi sihlole imingcele emisha kubuchwepheshe be-granite be-ZHHIMG. Kungakhathaliseki ukuthi sakha isiteji sokuthwala umoya esenziwe ngokwezifiso somkhiqizi we-semiconductor waseYurophu noma ipuleti lobuso eliqondile lelebhu ye-metrology yaseMelika, izimiso eziyinhloko zesayensi yezinto ezibonakalayo, ubunjiniyela bemishini, kanye nokulawula imvelo kusalokhu kuyisiqondiso sethu.

Njengoba ukukhiqiza kuqhubeka nohambo lwako olungapheli oluya ekuqondeni okuphakeme, indima yezingxenye ze-granite enembile izokhula ngokubaluleka. Lezi zakhiwo ezimangalisayo zivala igebe phakathi kwezwe lemishini neledijithali, zihlinzeka ngeplatifomu ezinzile lapho ubuchwepheshe bethu obuthuthukisiwe buthembele khona. Kwa-ZHHIMG, siyaziqhenya ngokuqhubekisela phambili ifa lobuciko be-granite enembile ngenkathi samukela izinto ezintsha ezizochaza ikusasa lokukhiqiza. Izitifiketi zethu ze-ISO 9001, ISO 45001, ISO 14001, kanye ne-CE ziwubufakazi bokuzibophezela kwethu ekhwalithini, ukuphepha, kanye nomthwalo wemfanelo wemvelo—amanani afakwe kuzo zonke izingxenye esiziklamayo nesizenzayo.

Ekugcineni, ukwakhiwa kwezingxenye zegranite okuphumelelayo kungaphezu nje kokuhlangabezana nezimfuneko; kumayelana nokuqonda injongo ejulile ngemuva kokulinganisa ngakunye, ukubekezelelana ngakunye, kanye nokuqedwa ngakunye kobuso. Kumayelana nokudala izixazululo ezivumela amakhasimende ethu ukuthi adlule imingcele yalokho okungenzeka ekukhiqizeni ngokunemba. Njengoba sibheke esikhathini esizayo, sisazinikele ekuthuthukiseni isayensi yokwakhiwa kwezingxenye zegranite, siqinisekisa ukuthi lezi zinto ezibalulekile ziyaqhubeka nokusekela ubuchwepheshe obusha obubumba umhlaba wethu.

Isikhathi sokuthunyelwe: Novemba-03-2025