Izingxenye zegranite ziyingxenye ebalulekile yemishini ye-semiconductor esetshenziswa enqubweni yokukhiqiza ama-microchip nama-circuits ahlanganisiwe. Lezi zingxenye zenziwe ngamatshe emvelo esezingeni eliphezulu aklanywe ukuze ahlangabezane nezidingo ezithile zemboni ye-semiconductor. Igranite iyindlela ethandwayo yokukhiqiza imishini ye-semiconductor ngenxa yamandla ayo avelele, ukuqina, kanye nokuqina kokushisa. Kulesi sihloko, sizohlola imisebenzi eyinhloko yezingxenye zegranite emishinini ye-semiconductor.

1. Ukudambisa Ukudlidliza

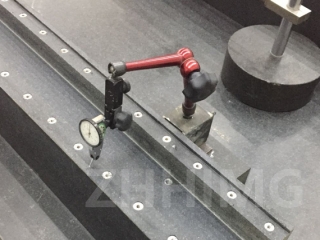

Omunye wemisebenzi eyinhloko yezingxenye ze-granite emishinini ye-semiconductor ukuhlinzeka ngokudambisa ukudlidliza. Ukukhiqizwa kwe-microchip kudinga indawo ehlanzekile nezinzile, futhi ukudlidliza kungabangela ukungcola futhi kuphazamise inqubo yokukhiqiza. Izingxenye ze-granite zisetshenziswa ezindaweni ezibalulekile zemishini ye-semiconductor, njenge-wafer chucks kanye nezigaba, ukuze zimunce futhi zinciphise ukudlidliza okubangelwa ukunyakaza kwemishini noma izici zangaphandle.

2. Ukuzinza Kokushisa

Izingxenye ze-granite zaziwa ngokuzinza kwazo okuhle kakhulu kokushisa. Inqubo yokukhiqiza i-semiconductor idinga amazinga okushisa aphezulu, futhi imishini kumele igcine amazinga okushisa azinzile ukuze kugwenywe amaphutha noma ukungasebenzi kahle. Izingxenye ze-granite zine-coefficient ephansi yokwanda kokushisa, okusho ukuthi azikhuli noma azinciphisi kakhulu ngokushintshashintsha kwezinga lokushisa. Lesi sici senza imishini ikwazi ukugcina amazinga okushisa azinzile futhi inciphise amazinga okushisa.

3. Ukuqina Okulinganayo

Omunye umsebenzi obalulekile wezingxenye ze-granite ukuzinza kobukhulu ezikunikezayo. Inqubo yokukhiqiza idinga ukunemba nokunemba, futhi imishini kumele igcine ubukhulu bayo obuqondile kuyo yonke inqubo. Izingxenye ze-granite zinokuqina okuphezulu kanye nokwanda okuphansi kokushisa, okusho ukuthi azinawo amathuba amaningi okuguquka okubangelwa ukushintsha kwezinga lokushisa noma amandla angaphandle. Lesi sici siqinisekisa ukuthi imishini igcina ubukhulu bayo obuqondile ngesikhathi senqubo yokukhiqiza.

4. Ukumelana namakhemikhali

Izingxenye ze-granite azinamakhemikhali futhi zimelana namakhemikhali amaningi asetshenziswa kakhulu embonini ye-semiconductor. Ukumelana namakhemikhali kubalulekile ngoba inqubo yokukhiqiza ihilela ukusetshenziswa kwamakhemikhali ahlukahlukene njenge-acids, izisekelo, kanye nezinyibilikisi ezingalimaza imishini. Izingxenye ze-granite zingamelana nokuchayeka kula makhemikhali, kuncishiswe ingozi yokulimala kwemishini futhi kuqinisekiswe ukuthi inqubo yokukhiqiza isebenza kahle.

5. Ukuhlanzeka

Izingxenye ze-granite kulula ukuzihlanza nokuzinakekela. Zinobuso obubushelelezi obuzenza kube lula ukuzisula futhi azinawo amabhaktheriya noma ezinye izinto ezingcolisayo, okwenza zibe zilungele ukusetshenziswa ezindaweni ezihlanzekile. Ukuhlanzeka kubalulekile enkambisweni yokukhiqiza i-semiconductor ukuvimbela ukungcoliswa kwama-microchip nokuqinisekisa ikhwalithi ehambisanayo.

Isiphetho

Izingxenye ze-granite zidlala indima ebalulekile emishinini ye-semiconductor futhi zinegalelo ekuqondeni nasekuqondeni okudingekayo enqubweni yokukhiqiza. Lezi zingxenye zihlinzeka ngokunciphisa ukudlidliza, ukuzinza kokushisa nobukhulu, ukumelana namakhemikhali, kanye nokuhlanzeka, okubalulekile ekusebenzeni kahle nangokuphumelelayo kwemishini. Njengoba ubuchwepheshe buthuthuka, isidingo semishini ye-semiconductor esezingeni eliphezulu sizoqhubeka nokukhula, futhi izingxenye ze-granite zizohlala ziyingxenye ebalulekile yale mishini.

Isikhathi sokuthunyelwe: Ephreli-08-2024