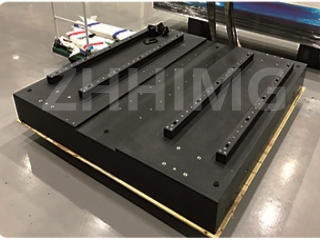

Izisekelo zomshini we-granite ziyingxenye ebalulekile endaweni yokusebenza yemishini yokucubungula i-wafer. Zihlinzeka ngesisekelo esiqinile nesiqinile esiqinisekisa ukuthi imishini isebenza ngokunembile nangokungaguquguquki. Kodwa-ke, ukuthi isisekelo somshini we-granite sisebenza kahle noma cha kuncike kakhulu endaweni yokusebenza. Kulesi sihloko, sizoxoxa ngezidingo zesisekelo somshini we-granite kanye nezindlela zokugcina indawo yokusebenza efanele.

Izidingo Zemvelo Zesisekelo Somshini We-Granite

Ukuhlanzeka: Indawo yokusebenza kufanele ingabi nothuli futhi ingabi nakungcola ukuze kugwenywe noma yiziphi izinhlayiya ezingafuneki ukuthi zingangeni futhi zilimaze izingxenye zesisekelo somshini. Noma iyiphi inhlayiya engena esisekelweni somshini ingabangela umonakalo omkhulu ezingxenyeni zemishini nezinyakazayo, okungaholela ekungasebenzi kahle kwemishini.

Ukuzinza: Isisekelo somshini we-granite senzelwe ukuba siqine futhi siqine, kodwa ngeke sibe usizo uma singabekwanga epulatifomu ezinzile. Indawo yokusebenza kufanele iqine, futhi phansi kufanele kube sezingeni. Noma yikuphi ukudlidliza noma ukugoba phansi kungabangela ukuthi isisekelo somshini sishintshe noma sihambe, okuzothinta ukunemba kokusebenza kwemishini. Ukuqinisekisa ukuthi imishini isebenza kahle, umshini kufanele ubekwe endaweni engenazo izidlidlizi, elinganayo noma uhlukaniswe nomhlabathi kusetshenziswa ama-dampener okudlidliza.

Ukulawulwa Kokushisa Nomswakama: Abakhiqizi abaningi bemishini batusa ibanga elithile lokushisa nomswakama lapho isisekelo somshini kufanele sisebenze khona ukuze sisebenze kahle kakhulu. Izinga lokushisa lendawo yokusebenza akufanele lidlule umkhawulo ophakanyisiwe womkhiqizi, futhi amazinga omswakama kufanele abe ngaphakathi kwezindinganiso zemboni. Noma yikuphi ukuphambuka ebangeni elinconywayo kungabangela ukwanda kokushisa nokuncipha kwe-granite, okuholela ekushintsheni kobukhulu kanye nokunemba okunciphile kwemishini.

Umoya Ongenisa Umoya: Indawo yokusebenza enomoya ongenisa kahle umoya inciphisa amathuba okufiphala, ukugqwala, kanye nokushisa, okwehlisa ukusebenza kahle kwemishini kanye nesisekelo somshini. Umoya ongenisa umoya ongenisa kahle umoya uyasiza futhi ekuphatheni izinga lokushisa kanye nomswakama.

Ukugcinwa Kwendawo Yokusebenza

Ukuhlanza Nokuhlanza: Indawo yokusebenza kufanele ihlanzeke futhi ingabi nakungcola, okuhlanganisa nezinhlayiya ezingabangela umonakalo ezingxenyeni eziyisisekelo zomshini. Inqubo yokuhlanza kufanele ibe ehlelekile futhi ilandele amazinga emboni ukuze kugwenywe noma yikuphi ukuklwebheka noma ukulimala kwezingxenye zomshini.

Ukulawulwa Kokudlidliza: Indawo yokusebenza kufanele ingabi nokudlidliza noma ibe nezinyathelo ezidingekayo zokulawula nokuhlukanisa ukudlidliza. Izinhlelo zokunciphisa ukudlidliza zisiza ukunciphisa imiphumela yokudlidliza esisekelweni somshini, okuqinisekisa indawo ezinzile yemishini.

Ukulawulwa Kokushisa Nomswakama: Izinga lokushisa nomswakama kufanele liqashwe futhi liphathwe njalo. Uhlelo lwe-HVAC lungasetshenziswa ukulawula izinga lokushisa nomswakama ngokususa umswakama nokugcina izinga lokushisa lizinzile. Ukunakekelwa njalo kuzogcina uhlelo lwe-HVAC lusebenza kahle.

Ukugcinwa Kwesistimu Yokungenisa Umoya: Ukuhlolwa njalo nokugcinwa kwesistimu yokungenisa umoya kubalulekile. Uhlelo kufanele lususe noma yiziphi izinhlayiya ezingafuneki futhi lugcine izinga lokushisa elidingekayo kanye nomswakama.

Ekuphetheni, indawo yokusebenza idlala indima ebalulekile ekusebenzeni nasekugcinweni kwesisekelo somshini we-granite. Ngakho-ke, kubalulekile ukugcina indawo yokusebenza ihlanzekile, izinzile, futhi inomoya ofanele ukuqinisekisa ukusebenza kahle kwemishini. Ukugcinwa njalo kwendawo yokusebenza kanye nokunamathela ezindinganisweni zemboni kuzoqinisekisa ukuthi isisekelo somshini sihlala isikhathi eside, okuholela empilweni ende yemishini kanye nokusebenza kahle.

Isikhathi sokuthunyelwe: Disemba-28-2023