Izingxenye zemishini ye-Granite zivame ukusetshenziswa kumadivayisi okucubungula ngokunemba ngenxa yokuzinza kwawo okuphezulu, ukuqina, kanye ne-coefficient ephansi yokushisa yokunwetshwa. Kodwa-ke, lezi zingxenye zinezidingo eziqondile zendawo yokusebenza ukuze zigcine ukusebenza kahle kwazo futhi ziqinisekise ukuthi aziwohloki ngokuhamba kwesikhathi. Kulesi sihloko, sizocubungula izidingo zezingxenye zemishini ye-granite zokucubungula imikhiqizo yedivayisi ngokunemba endaweni yokusebenza kanye nendlela yokugcina indawo yokusebenza.

1. Izinga lokushisa

Izingxenye zemishini ye-Granite ziyazwela ekushintsheni kwezinga lokushisa. Izinga lokushisa elilungile lokusebenza lezingxenye ze-granite ngu-20-25°C. Uma izinga lokushisa liphezulu kakhulu noma liphansi kakhulu, lingabangela izinguquko kubukhulu bezingxenye ze-granite. Ngakho-ke, kuyadingeka ukuqinisekisa izinga lokushisa elihlala njalo endaweni yokusebenza ngokusebenzisa i-air conditioning noma izinhlelo zokushisa. Izinga lokushisa kufanele ligcinwe ngaphakathi kwebanga lika-18-26°C ukuze kuqinisekiswe izilinganiso ezinembile nezizinzile.

2. Umswakama

Izingxenye ze-Granite nazo zizwela umswakama kanye nomswakama. Amazinga omswakamo aphezulu angabangela ukugqwala nokuguga, okungathinta ukunemba kwezilinganiso. Ngakho-ke, indawo yokusebenza kufanele igcinwe ezingeni lomswakama we-40-60%. Lokhu kungafezwa ngokusebenzisa ama-dehumidifiers noma ngokuqinisekisa ukungena komoya ngendlela efanele.

3. Ukudlidliza

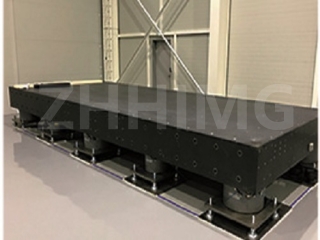

Ukudlidliza kungabangela izingxenye zegwadle ukuthi ziguge futhi zilahlekelwe ukunemba kwazo. Ngakho-ke, kubalulekile ukugwema imithombo yokudlidliza endaweni yokusebenza. Lokhu kungafezwa ngokuhlukanisa umshini noma izinto zokusebenza lapho izingxenye zifakwe khona endaweni ezungezile. Kuyanconywa futhi ukusebenzisa izinto ezibamba ukushaqeka ukuze unciphise imiphumela yokudlidliza.

4. Uthuli nemfucumfucu

Izingxenye ze-Granite zingenwa kalula wuthuli nemfucumfucu. Uthuli nemfucumfucu kungabangela ukuguga, okuholela emaphutheni esilinganisweni kanye nokunemba. Ngakho-ke, kuyadingeka ukugcina indawo yokusebenza ehlanzekile engenalo uthuli nemfucumfucu. Lokhu kungafezwa ngokuhlanza njalo nokusula indawo yokusebenza.

5. Isondlo

Ukugcinwa njalo kwezingxenye zegwadle kubalulekile ukuze kuqinisekiswe ukuphila kwazo isikhathi eside nokunemba. Izingxenye kufanele zihlolwe njalo ukuze ziguge. Noma yiziphi izimpawu zokuguga kufanele zilungiswe ngokushesha. Futhi, ukulinganisa okuvamile kwemishini kufanele kwenziwe ukuze kuqinisekiswe ukunemba.

Sengiphetha, izingxenye zemishini ye-granite zidlala indima ebalulekile ekucubunguleni ukunemba kwemikhiqizo yedivayisi. Ukuqinisekisa ukuthi lezi zingxenye zisebenza ngendlela efanele, kuyadingeka ukugcina indawo yokusebenza elawulwayo nehlanzekile. Ukugcina izinga lokushisa elingaguquki, umswakama, nokugwema ukudlidliza kubalulekile ekulinganiseni okunembile. Uthuli kanye nemfucumfucu kufanele kugcinwe okungenani, futhi ukugcinwa njalo kwezingxenye kuyadingeka. Ngokulandela le mihlahlandlela, ubude bempilo bezingxenye zegwadle buzonwetshwa, futhi imikhiqizo yedivayisi yokucubungula ukunemba izohlala inemba futhi ithembekile.

Isikhathi sokuthumela: Nov-25-2023