Imishini yokucubungula i-wafer iyithuluzi elibalulekile enkambisweni yokukhiqiza izingxenye ze-elekthronikhi. Le mishini isebenzisa izingxenye ze-granite ukuqinisekisa ukuzinza nokunemba ngesikhathi senqubo yokukhiqiza. I-Granite iyidwala elivela ngokwemvelo elinokuqina okuhle kokushisa kanye nezakhiwo zokukhulisa ukushisa eziphansi, okwenza kube yinto efanelekile yokusetshenziswa emishinini yokucubungula i-wafer. Kulesi sihloko, sizobheka izidingo zezingxenye ze-granite zemishini yokucubungula i-wafer endaweni yokusebenza kanye nendlela yokugcina indawo yokusebenza.

Izidingo Zezingxenye Zegranite Zemishini Yokucubungula I-Wafer Endaweni Yokusebenza

1. Ukulawula Izinga Lokushisa

Izingxenye zegranite ezisetshenziswa emishinini yokucubungula i-wafer zidinga indawo yokusebenza ezinzile ukuze zilondoloze ukunemba kwazo. Indawo yokusebenza kumele igcinwe ngaphakathi kwebanga elithile lokushisa ukuqinisekisa ukuthi izingxenye zegranite azikhuli noma azinciphi. Ukushintshashintsha kwezinga lokushisa kungabangela ukuthi izingxenye zegranite zande noma zinciphe, okungabangela ukungalungi ngesikhathi senqubo yokukhiqiza.

2. Ukuhlanzeka

Izingxenye zegranite zemishini yokucubungula i-wafer zidinga indawo yokusebenza ehlanzekile. Umoya endaweni yokusebenza kufanele ungabi nezinhlayiya ezingangcolisa imishini. Izinhlayiya ezisemoyeni zingahlala ezingxenyeni zegranite futhi ziphazamise inqubo yokukhiqiza. Indawo yokusebenza kufanele futhi ingabi nothuli, imfucumfucu, nezinye izinto ezingcolisayo ezingathinta ukunemba kwemishini.

3. Ukulawula Umswakama

Amazinga aphezulu omswakama angabangela izinkinga ngezingxenye zegranite zemishini yokucubungula i-wafer. Igranite inezimbobo futhi ingamunca umswakama ovela endaweni ezungezile. Amazinga aphezulu omswakama angabangela ukuthi izingxenye zegranite zivuvuke, okungathinta ukunemba kwemishini. Indawo yokusebenza kufanele igcinwe ezingeni lomswakama eliphakathi kuka-40-60% ukuvimbela le nkinga.

4. Ukulawula Ukudlidliza

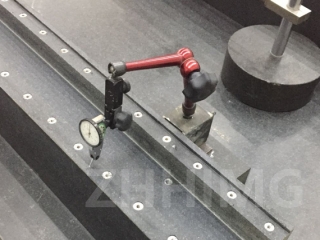

Izingxenye zegranite ezisetshenziswa emishinini yokucubungula i-wafer zizwela kakhulu ekudlidlizeni. Ukudlidliza kungabangela ukuthi izingxenye zegranite zinyakaze, okungabangela ukungalungi ngesikhathi senqubo yokukhiqiza. Indawo yokusebenza kufanele ingabi nemithombo yokudlidliza njengemishini esindayo kanye nokuminyana kwezimoto ukuze kuvinjelwe le nkinga.

Indlela Yokulondoloza Indawo Yokusebenza

1. Ukulawula Izinga Lokushisa

Ukugcina izinga lokushisa lizinzile endaweni yokusebenza kubalulekile emishinini yokucubungula i-wafer. Izinga lokushisa kufanele ligcinwe ngaphakathi kwebanga elichazwe umenzi. Lokhu kungafezwa ngokufaka amayunithi okupholisa umoya, ukuvikela ukushisa, kanye nezinhlelo zokuqapha izinga lokushisa ukuqinisekisa ukuthi imishini isebenza endaweni ezinzile.

2. Ukuhlanzeka

Ukugcina indawo yokusebenza ihlanzekile kubalulekile ekusebenzeni kahle kwemishini yokucubungula i-wafer. Izihlungi zomoya kufanele zishintshwe njalo, futhi amapayipi omoya kufanele ahlanzwe njalo ukuvimbela ukunqwabelana kothuli nezinhlayiya. Izitezi kanye nezindawo kufanele kuhlanzwe nsuku zonke ukuvimbela ukunqwabelana kodoti.

3. Ukulawula Umswakama

Ukugcina izinga lomswakama elizinzile kubalulekile ekusebenzeni kahle kwemishini yokucubungula i-wafer. I-dehumidifier ingasetshenziswa ukugcina izinga lomswakama elidingekayo. Izinzwa zomswakama nazo zingafakwa ukuze ziqaphe izinga lomswakama endaweni yokusebenza.

4. Ukulawula Ukudlidliza

Ukuze kuvinjelwe ukudlidliza ukuthi kungathinti imishini yokucubungula i-wafer, indawo yokusebenza kumele ingabi nemithombo yokudlidliza. Imishini enzima kanye nethrafikhi kufanele kubekwe kude nendawo yokukhiqiza. Izinhlelo zokunciphisa ukudlidliza nazo zingafakwa ukuze zimunce noma yikuphi ukudlidliza okungenzeka.

Ekuphetheni, izingxenye zegranite zemishini yokucubungula i-wafer zidinga indawo yokusebenza ezinzile nelawulwayo ukuqinisekisa ukunemba nokuthembeka ngesikhathi senqubo yokukhiqiza. Ukulawulwa kokushisa, ukuhlanzeka, ukulawula umswakama, kanye nokulawula ukudlidliza kubalulekile ukuze kugcinwe ukusebenza kahle kwemishini. Ukugcinwa njalo nokuqapha indawo yokusebenza kubalulekile ukuvimbela noma yiziphi izinkinga ezingathinta ukusebenza kwemishini. Ngokulandela le mihlahlandlela, abakhiqizi bangakhulisa ukusebenza kwemishini yabo yokucubungula i-wafer futhi bakhiqize izingxenye ze-elekthronikhi ezisezingeni eliphezulu.

Isikhathi sokuthunyelwe: Jan-02-2024