Ezweni lokukhiqiza ngokunemba okukhulu, ukusebenza kwezingxenye ze-granite mechanical kuhlobene kakhulu nezici zazo zobuso—ikakhulukazi ubulukhuni nokucwebezela. Lezi zinhlaka ezimbili zingaphezu nje kwemininingwane yobuhle; zithinta ngqo ukunemba, ukuzinza, kanye nokuthembeka kwezinsimbi zokunemba. Ukuqonda ukuthi yini enquma ubulukhuni nokucwebezela kwezingxenye ze-granite kusiza onjiniyela kanye nochwepheshe ukuqinisekisa ukuthi ingxenye ngayinye ihlangabezana nezindinganiso eziqinile ezidingekayo ekusetshenzisweni ngokunemba okuphezulu.

I-Granite iyinto yemvelo eyakhiwe kakhulu yi-quartz, i-feldspar, kanye ne-mica, ezakha isakhiwo esiqinile nesinohlamvu oluhle kakhulu ekusetshenzisweni kwemishini kanye ne-metrological. Ubulukhuni bomphezulu wezingxenye zemishini ye-granite buvame ukuba phakathi kuka-Ra 0.4 μm no-Ra 1.6 μm, kuye ngokuthi izinga, indlela yokupholisha, kanye nokusetshenziswa okuhlosiwe. Isibonelo, izindawo zokulinganisa zamapuleti noma izisekelo ze-granite zidinga amanani aphansi kakhulu obulukhuni ukuqinisekisa ukuthintana okunembile nezinsimbi kanye nezinto zokusebenza. Inani eliphansi le-Ra lisho indawo ebushelelezi, ukunciphisa ukungqubuzana nokuvimbela amaphutha okulinganisa abangelwa ukungalungi komphezulu.

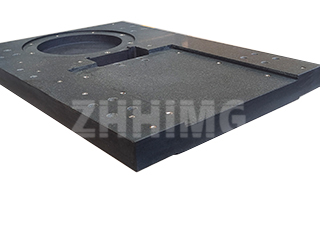

Kwa-ZHHIMG, ingxenye ngayinye yegranite icutshungulwa ngokucophelela kusetshenziswa amasu okugoqa anembile kakhulu. Ubuso bulinganiswa futhi bucwengisiswa ngokuphindaphindiwe kuze kube yilapho bufinyelela ukuqina okufiswayo kanye nokuthungwa okufanayo. Ngokungafani nezindawo zensimbi, ezingadinga ukumbozwa noma ukwelashwa ukuze kugcinwe ubushelelezi, igranite ifinyelela ukuqina kwayo okuhle ngokwemvelo ngokupholisha okulawulwayo komshini. Lokhu kuqinisekisa ubuso obuhlala isikhathi eside obugcina ukunemba ngisho nangemva kokusetshenziswa isikhathi eside.

Ngakolunye uhlangothi, ukukhazimula kubhekisela kwikhwalithi ebonakalayo nekhanyayo yomphezulu we-granite. Ezingxenyeni ezinembile, ukukhazimula ngokweqile akufiseleki, njengoba kungabangela ukukhanya okuphazamisa ukulinganisa okubonakalayo noma kwe-elekthronikhi. Ngakho-ke, izindawo ze-granite zivame ukuqedwa ngokubukeka oku-semi-matte — okubushelelezi uma kuthintwa kodwa ngaphandle kokukhanya okufana nesibuko. Leli zinga elikhanyayo elilinganiselayo lithuthukisa ukufundwa ngesikhathi sokulinganisa futhi liqinisekisa ukuzinza kokukhanya kumathuluzi okunemba njengemishini yokulinganisa ehlanganisiwe (ama-CMM) kanye nezigaba zokukhanya.

Izici eziningana zithinta kokubili ubulukhuni kanye nokucwebezela, okuhlanganisa ukwakheka kwamaminerali e-granite, ubukhulu bezinhlamvu, kanye nendlela yokupholisha. I-granite emnyama esezingeni eliphezulu, njenge-ZHHIMG® Black Granite, iqukethe amaminerali amahle, asatshalaliswe ngokulinganayo avumela ukuqedwa okuphezulu kwendawo enokukhanya okuzinzile kanye nokugoba okuncane kwendawo. Lolu hlobo lwe-granite luphinde lunikeze ukumelana okuhle kakhulu nokuguguleka kanye nokuqina kobukhulu, okubalulekile ekugcineni ukunemba kwesikhathi eside.

Ukuze kulondolozwe isimo sobuso bezingxenye ze-granite, ukunakekelwa okufanele kubalulekile. Ukuhlanza njalo ngendwangu ethambile, engena-lint kanye nesihlanzi esingagqwali kusiza ukususa uthuli kanye nezinsalela zamafutha ezingathinta kokubili ukujiya kanye nokubukeka okucwebezelayo. Izindawo akufanele zihlikihlwe ngamathuluzi ensimbi noma izinto ezihudulayo, njengoba lokhu kungaletha imihuzuko emincane eshintsha ukuthungwa kobuso kanye nokunemba kokulinganisa. Ngokunakekelwa okufanele, izingxenye ze-granite mechanical zingagcina izici zazo zobuso obunembile amashumi eminyaka.

Ekuphetheni, ubulukhuni nokucwebezela kwezingxenye ze-granite mechanical kubalulekile ekusebenzeni kwazo kobunjiniyela bokunemba. Ngezinqubo zokukhiqiza ezithuthukisiwe, i-ZHHIMG iqinisekisa ukuthi yonke ingxenye ye-granite ihlangabezana nezindinganiso zomhlaba wonke zekhwalithi yomhlaba, ukuzinza, kanye nokuphila isikhathi eside. Ngokuhlanganisa izakhiwo zomzimba ezihlukile ze-granite yemvelo nobuchwepheshe obusezingeni eliphezulu, i-ZHHIMG iyaqhubeka nokusekela izimboni lapho ukunemba nokuthembeka kuveza impumelelo.

Isikhathi sokuthunyelwe: Okthoba-28-2025