Enhliziyweni yemboni enembile kakhulu—kusukela ekukhiqizeni ama-semiconductor kuya ku-metrology yezindiza—kukhona ipulatifomu ye-granite. Ngokuvamile inganakwa njengebhulokhi eliqinile letshe, le ngxenye, empeleni, iyisisekelo esibaluleke kakhulu nesizinzile sokufeza izilinganiso ezinembile nokulawula ukunyakaza. Konjiniyela, ososayensi be-metro, kanye nabakhi bemishini, ukuqonda ukuthi yini echaza ngempela “ukunemba” kwepulatifomu ye-granite kubaluleke kakhulu. Akukhona nje ngokuqedwa kwendawo; kumayelana neqoqo lezinkomba zejometri ezilawula ukusebenza kwepulatifomu yangempela.

Izinkomba ezibaluleke kakhulu zokunemba kwepulatifomu yegranite yi-Flatness, Straightness, kanye ne-Parallelism, konke okumele kuqinisekiswe ngokwezindinganiso zomhlaba wonke eziqinile.

Ukuthamba: Indiza Eyinhloko Yokubhekisela

Ukuthamba kungenye yezinkomba ezibaluleke kakhulu kunoma iyiphi ipulatifomu ye-granite enembile, ikakhulukazi i-Granite Surface Plate. Kuchaza ukuthi yonke indawo yokusebenza ihambisana kangakanani nendiza ephelele yomqondo. Empeleni, kuyinkomba eyinhloko lapho kuthathwa khona zonke ezinye izilinganiso.

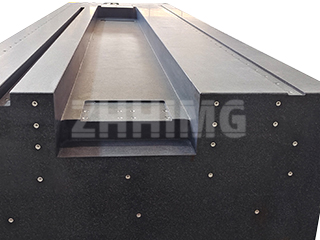

Abakhiqizi abanjengo-ZHHIMG baqinisekisa ukuthi i-flat ihambisana nezindinganiso eziqashelwa emhlabeni wonke njenge-DIN 876 (eJalimane), i-ASME B89.3.7 (e-USA), kanye ne-JIS B 7514 (eJapane). Lezi zindinganiso zichaza amazinga okubekezelela, ngokuvamile asukela ku-Grade 00 (Ibanga Lelebhu, afuna ukunemba okuphezulu kakhulu, ngokuvamile ku-sub-micron noma i-nanometer range) kuya ku-Grade 1 noma 2 (Ibanga Lokuhlola noma Legumbi Lamathuluzi). Ukufinyelela i-flat-grade grade ngelabhorethri akudingi nje kuphela ukuzinza okungokwemvelo kwe-granite enobukhulu obuphezulu kodwa futhi nekhono eliyingqayizivele labadlali abangochwepheshe be-lappers—izingcweti zethu ezingafinyelela ngesandla lokhu kubekezelelana ngokunemba okuvame ukubizwa ngokuthi “umuzwa we-micrometer.”

Ukuqonda: Umgogodla Wokunyakaza Okuqondile

Nakuba ukuthamba kubhekisela endaweni enezinhlangothi ezimbili, ukuthamba kusebenza emgqeni othize, ngokuvamile emaphethelweni, eziqondisweni, noma emigodini yengxenye yegranite njengomphetho oqondile, isikwele, noma isisekelo somshini. Ekwakhiweni komshini, ukuthamba kubalulekile ngoba kuqinisekisa indlela yangempela, eqondile yama-axes okunyakaza.

Uma isisekelo segranite sisetshenziswa ukufaka iziqondiso eziqondile noma ama-air bearings, ukuqondile kwezindawo zokufaka kuhumusha ngqo iphutha eliqondile lesigaba sokuhamba, kuthinte ukunemba kokubeka kanye nokuphindeka. Amasu okulinganisa athuthukisiwe, ikakhulukazi lawo asebenzisa ama-laser interferometers (ingxenye eyinhloko yephrothokholi yokuhlola ye-ZHHIMG), ayadingeka ukuqinisekisa ukuphambuka kokuqondile endaweni yama-micrometer ngemitha, ukuqinisekisa ukuthi ipulatifomu isebenza njengomgogodla ongenaphutha wezinhlelo zokunyakaza eziguquguqukayo.

Ukufana kanye nokuma okuqondile: Ukuchaza ukuvumelana kweJomethrikhi

Ezingxenyeni zegranite eziyinkimbinkimbi, njengezisekelo zomshini, iziqondiso zokuthwala umoya, noma izingxenye ezinezinhlangothi eziningi njengezikwele zegranite, izinkomba ezimbili ezengeziwe zibalulekile: Ukufana kanye Nokubambelela (Isikwele).

- Ukuhambisana kusho ukuthi izindawo ezimbili noma ngaphezulu—njengezindawo zokufaka eziphezulu nezingezansi zomqadi wegranite—ziqhelelene kakhulu. Lokhu kubalulekile ekugcineni ukuphakama kokusebenza okungaguquki noma ukuqinisekisa ukuthi izingxenye ezisemaceleni ahlukene omshini ziqondaniswe kahle.

- Ukuma okuqondile, noma isikwele, kuqinisekisa ukuthi izindawo ezimbili zilingana kahle no-90° komunye nomunye. Kumshini ojwayelekile wokulinganisa i-Coordinate (CMM), i-granite square ruler, noma isisekelo se-component uqobo, kumele sibe nokuqina okuqondile okuqinisekisiwe ukuze kuqedwe iphutha lika-Abbe futhi kuqinisekiswe ukuthi ama-X, Y, kanye ne-Z aqondile ngempela.

Umehluko we-ZHHIMG: Ngale Kwencazelo

Kwa-ZHHIMG, sikholelwa ukuthi ukunemba akukwazi ukucaciswa ngokweqile—Ibhizinisi lokunemba alikwazi ukuba nzima kakhulu. Ukuzibophezela kwethu kudlula ukuhlangabezana nalezi zindinganiso zobukhulu. Ngokusebenzisa i-ZHHIMG® Black Granite enobukhulu obuphezulu (≈ 3100 kg/m³), amapulatifomu ethu ngokwemvelo anokuvinjelwa kokudlidliza okuphezulu kanye ne-coefficient yokwanda kokushisa ephansi kakhulu, okuvikela kakhulu ukuthamba okuqinisekisiwe, ukunemba, kanye nokuhambisana kokuphazamiseka kwemvelo nokusebenza.

Uma uhlola ipulatifomu ye-granite enembile, ungabheki nje kuphela ishidi lemininingwane kodwa nendawo yokukhiqiza, izitifiketi, kanye nokulawulwa kwekhwalithi okulandelekayo—zona kanye izakhi ezenza ingxenye ye-ZHHIMG® ibe yisinqumo esizinzile nesithembekile kakhulu sezinhlelo zokusebenza ezidinga kakhulu ukucaca okuphezulu emhlabeni.

Isikhathi sokuthunyelwe: Okthoba-24-2025