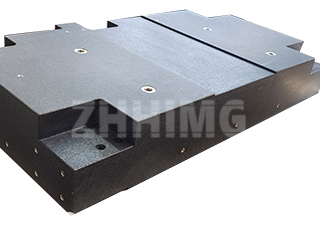

Indima Ye-Granite Core

I-granite crossbeam ingaphezu kakhulu kwesakhi esilula; iyithuluzi lokubhekisela ngokunemba—umgogodla oqinisekisiwe wanoma yiluphi uhlelo lwe-metrology oluthuthukisiwe noma lwe-machining. Ezihlanganisweni ezisukela kuma-gantry cutters kuya kumishini yokulinganisa eyinkimbinkimbi (ama-CMM), i-granite isebenza njengebhentshi lokusebenzela eliyisicaba ngokuphelele, elingaguquki elidingekayo ekubhaleni, ekulinganiseni, nasekuhlanganiseni ukunyakaza okuyinkimbinkimbi kwemishini.

Ukuqina okungokwemvelo kwe-granite—ukumelana kwayo nokugqwala, i-asidi, i-magnetism, kanye nokushintshashintsha kwezinga lokushisa—kuvumela ochwepheshe ukuthi bagxile kuphela ekunembeni kwezingxenye ezihambayo ezifakwayo. Uma wakha phezu kwe-ZHHIMG® granite crossbeam, wakha phezu kwe-plane ephelele. Kodwa-ke, ngisho ne-plane ephelele idinga ukwenziwa ngokucophelela ngesikhathi sokuhlanganiswa kwezingxenye.

Isisekelo Somhlangano Ongenaphutha

Ukuze umshini wokugcina ufeze futhi ulondoloze ukunemba kwawo okudingekayo, yonke into enamathiselwe emthini we-granite kumele ilandele amazinga aqinile ekhwalithi kanye nokulungiselela. Yilapho ukuhlanganiswa kwemishini kushintsha khona kusuka kubuciko kuya kwisayensi:

1. Ukulungiselela: I-Slate Ehlanzekile Kakhulu

Ngaphambi kokuba kuqhathaniswe, yonke ingxenye kumele ihlanzeke ngokuphelele. Lokhu akukhona nje ngokubukeka; kumayelana nokususa izinto ezincane ezingcolisa ukunemba. Zonke izinsalela zesihlabathi se-foundry, ukugqwala, kanye nemfucumfucu kumele kususwe ngokucophelela. Ezingxenyeni eziyinkimbinkimbi njengemigodi yangaphakathi noma izingxenye ze-gantry, ukufaka upende wangaphakathi wokuvikela ukugqwala ngemva kokuhlanza kuyisinyathelo esibalulekile. Idizili, i-parafini, noma uphethiloli kuvame ukusetshenziswa njengoketshezi lokuhlanza ukuncibilikisa uwoyela namafutha, kulandelwe ukomiswa kahle ngomoya ocindezelwe ukuvimbela noma yiziphi izinsalela ukuthi zingangeni engozini.

2. Ubuqotho Nokulingana Okulinganayo

Isimiso esiyinhloko sokuhlanganiswa okunembile silula: ubukhulu kumele bube bunembile. Ngesikhathi sokuhlanganiswa ku-granite crossbeam, ochwepheshe kumele bahlole kabusha—noma okungenani, benze ukuhlola okungahleliwe—kwazo zonke izilinganiso ezibalulekile zokuhlangana. Lokhu kufaka phakathi ibanga eliqondile eliphakathi nendawo, ukulingana phakathi kwamajenali amakhulu nama-bearings, kanye nokubekezelelana kwezimbobo zokufaka ama-bearings. Noma yikuphi ukuphambuka lapha kuzohumusha ngqo ekugijimeni, ukudlidliza, noma isikhathi sokuphila somshini esincishisiwe. Ngaphezu kwalokho, izindawo ezihlangene kumele zibe bushelelezi futhi zibushelelezi ngokuphelele. Noma yiziphi izimbobo noma ukuguquguquka kumele kunqunywe ukuqinisekisa ukuthi izingxenye zithola ukuthintana okugcwele, okuqinile ebusweni be-granite ngaphandle kokugoba noma izikhala.

3. Ukugcoba Nokuvala: Ukuvikela Ukunyakaza

Ukuqinisekisa ukuthi izingxenye zemishini zihamba kahle futhi zimelana nokuguguleka, ukugcotshwa nokuvalwa okufanele akuxoxiswana ngakho. Izindawo zokuhlangana, ikakhulukazi ngaphakathi kwezinhlangano zokuthwala ebhokisini le-spindle noma amantongomane omshini wokuphakamisa, kumele zigcotshwe kusengaphambili ngaphambi kokuxhuma.

Izivalo, njenge-O-rings, kumele ziphathwe ngokucophelela okukhulu. Kumelwe zicindezelwe zihambisana nemisele yazo, ngaphandle kokusonta noma ukuguquka, futhi indawo yokuvala kumele ingabi nomonakalo noma imihuzuko. Isivalo esithintekile simema ukungcola, okuyisitha sokunemba.

4. Ukunemba Kokunyakaza Okujikelezayo Nokuqondile

Izinhlangano ezihilela ukudluliswa kwamandla, njengezinhlelo zamasondo, igiya, noma ama-pulley, zinemingcele eyengeziwe yejometri.

Ukuze kuhlanganiswe igiya, ama-axes amagiya amabili kumele ahambisane kahle futhi ahambisane, kuqinisekiswe ukuthi izinyo libuyela emuva ngendlela efanele, efanayo. Ngokufanayo, ukuze kuhlanganiswe i-pulley, ama-axes kumele ahambisane, futhi izikhungo ze-groove kumele ziqondaniswe kahle. Ukuphambuka okukhulu kwe-axial noma ukungalungi kahle kuzobangela ukucindezeleka okungalingani, okuholela ekusheleleni kwebhande, ukudlidliza ngokweqile, kanye nokuguguleka okusheshayo—konke okuphazamisa ukuzinza okunikezwa yisisekelo se-granite. Ukukhetha isethi yebhande le-V elihambisanayo ngaphambi kokufakwa kubalulekile ukuvimbela ukudlidliza ngesikhathi sokudluliselwa kwamandla.

5. Ukufakwa Kwebhereyi: Iphuzu Lokunemba Okuphezulu Kakhulu

Ukuhlanganiswa kwamabhere kudinga ukunakekelwa okuphezulu kakhulu. Ngemva kokususa upende wokulwa nokugqwala nokuhlanza kahle ibhere, ochwepheshe kumele bahlole izinto zomgwaqo kanye nokugoqa ukuze babone ukuthi ziyagqwala yini futhi baqinisekise ukujikeleza okuguquguqukayo. Ngesikhathi sokufakwa, amandla kumele asetshenziswe ngokulinganayo nangokulinganayo endandatho yangaphakathi noma yangaphandle, kusetshenziswa amathuluzi afanele ukuvimbela ukushayisana noma ukuthambekela. Amandla kumele afaneleke—uma kudingeka ingcindezi enkulu, ukuhlanganiswa kumele kume ngokushesha ukuze kuhlolwe, njengoba lokhu kubonisa ukungalingani okukhulu kobukhulu obungalimaza ibhere futhi kubeke engcupheni yonke inhlangano.

Ngokuhlanganisa ubuqotho besakhiwo obungaguquki be-ZHHIMG® granite crossbeam nalezi zidingo zokuhlanganisa eziqinile, onjiniyela baqinisekisa ukuthi umshini ophumayo usebenza ngokunemba okuqhubekayo, kwezinga le-nanometer okulindelwe yimboni yomhlaba wonke enembile kakhulu.

Isikhathi sokuthunyelwe: Novemba-12-2025