Izingxenye Zokucacisa I-Granite: Izinto Okufanele Uzicabangele Lapho Uhlanganisa Umshini we-VMM

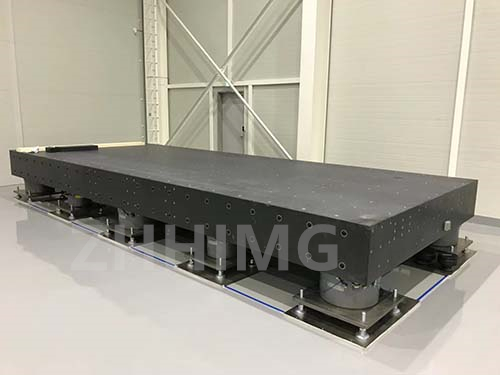

Uma kukhulunywa ngokuhlanganisa izingxenye zokunemba kwe-granite emshinini we-VMM (Vision Measuring Machine), kunezinto eziningana okudingeka zicatshangelwe ngokucophelela ukuqinisekisa ukusebenza kahle kanye nokunemba. I-Granite iyindlela ethandwayo yokukhetha izingxenye zokunemba ngenxa yokuqina kwayo okuhle kakhulu, ukuqina okuphezulu, kanye nokumelana nokuguguleka nokugqwala. Kodwa-ke, ukuze kusetshenziswe ngokugcwele izinzuzo ze-granite emshinini we-VMM, lezi zinto ezilandelayo kufanele zicatshangelwe:

1. Ikhwalithi Yezinto Ezisetshenziswayo: Ikhwalithi yegranite esetshenziselwa izingxenye ezinembile ibalulekile. Igranite esezingeni eliphezulu enobuningi obufanayo kanye nokucindezeleka okuncane kwangaphakathi kubalulekile ekufinyeleleni izilinganiso ezinembile nezithembekile emshinini we-VMM.

2. Ukuzinza Kokushisa: Ukuzinza kokushisa kwe-Granite kuyinto ebalulekile okufanele icatshangelwe, njengoba ukushintshashintsha kwezinga lokushisa kungathinta ukunemba kobukhulu bezingxenye. Kubalulekile ukukhetha i-granite enezakhiwo zokukhulisa ukushisa eziphansi ukuze kuncishiswe umthelela wokushintshashintsha kwezinga lokushisa ekusebenzeni komshini.

3. Izici Zokuqina Nokumanzisa: Izakhiwo zokuqina nokumanzisa zezingxenye zegranite zidlala indima ebalulekile ekunciphiseni ukudlidliza nokuqinisekisa izilinganiso ezizinzile. Ukuhlanganisa igranite nokuqina okuphezulu kanye nezici ezinhle kakhulu zokumanzisa kungathuthukisa ukunemba okuphelele kanye nokuphindaphindwa komshini we-VMM.

4. Ukuphela Komphezulu Nokuthamba: Ukuphela komphezulu kanye nokuthamba kwezingxenye ze-granite kubalulekile ekufinyeleleni izilinganiso ezinembile. Kufanele kuqashelwe ngokucophelela izinqubo zokukhiqiza ukuqinisekisa ukuthi izindawo ze-granite zibushelelezi, zithe tyaba, futhi azinazo iziphambeko ezingalimaza ukunemba komshini we-VMM.

5. Ukukhweza Nokuqondanisa: Ukukhweza nokuqondanisa okufanele izingxenye zokunemba kwe-granite ngaphakathi komshini we-VMM kubalulekile ekugcineni ubuqotho bezilinganiso. Amasu okufaka ngokunembile kanye nezinqubo zokuqondanisa ngokucophelela kufanele kusetshenziswe ukuqinisekisa ukuthi izingxenye ze-granite zisebenza kahle ngaphakathi komshini.

6. Izinto Ezicatshangelwayo Ngezemvelo: Indawo yokusebenza komshini we-VMM kufanele icatshangelwe lapho kuhlanganiswa izingxenye zokunemba kwe-granite. Izinto ezifana nokulawula izinga lokushisa, amazinga omswakama, kanye nokuchayeka ezintweni ezingcolisayo kufanele ziphathwe ukuze kulondolozwe ukuzinza kobukhulu kanye nokusebenza kwezingxenye ze-granite.

Ekuphetheni, ukuhlanganisa izingxenye zokunemba kwe-granite emshinini we-VMM kudinga ukunaka ngokucophelela ikhwalithi yezinto ezibonakalayo, ukuzinza kokushisa, ukuqina, ukuqeda ubuso, ukufakwa, ukuhambisana, kanye nezici zemvelo. Ngokubhekana nalezi zinto ezibalulekile, abakhiqizi bangenza ngcono ukusebenza nokunemba kwemishini yabo ye-VMM, ekugcineni kuthuthukiswe ikhwalithi nokuthembeka kwezinqubo zabo zokulinganisa.

Isikhathi sokuthunyelwe: Julayi-02-2024