Ukuhlanganiswa kwe-Granite kuyingxenye ebalulekile kumadivayisi wenqubo yokukhiqiza i-semiconductor. Iwuhlaka olubalulekile lokusekela oluhlinzeka ngendawo ezinzile neyisicaba yezinqubo zokukhiqiza eziyinkimbinkimbi ezibandakanyeka embonini ye-semiconductor. I-Granite inezakhiwo ezihlukile eziyenza ibe yinketho efanelekile ukuthi isetshenziswe ekwenziweni kwe-semiconductor.

Okokuqala, i-granite iyimpahla eqinile futhi ehlala isikhathi eside. Iyakwazi ukumelana nokuklwebheka, ukuguga nokubola kanye nokugqwala kwamakhemikhali. Lokhu kusho ukuthi iyinto efanelekile ukuthi isetshenziswe ezinqubweni zokukhiqiza i-semiconductor, njengoba ingaphenduli ngamakhemikhali nama-asidi asetshenziswa enqubweni yokukhiqiza, angalimaza ezinye izinhlobo zezinto.

Okwesibili, i-granite inokusimama okuhle kakhulu kwe-thermal. Lokhu kusho ukuthi iyakwazi ukugcina ukwakheka kwayo nokuzinza kwe-dimensional ngisho nalapho ingaphansi kwamazinga okushisa aphezulu. Lokhu kubalulekile ezinqubweni zokukhiqiza ama-semiconductor, lapho izinga lokushisa eliphezulu livame ukusetshenziselwa ukuncibilika nokuhlanganisa izinto ndawonye. Ngaphandle kokuzinza kokushisa, izakhi zingasonteka noma zishintshe ukuma, okuholela ekulimaleni komkhiqizo wokugcina.

Okwesithathu, i-granite inokusimama okuyingqayizivele, okuyivumela ukuthi igcine ukwakheka nosayizi wayo ngokuhamba kwesikhathi. Lokhu kubalulekile ezinqubweni zokukhiqiza ze-semiconductor lapho ukunemba nokunemba kubalulekile. Ngaphandle kokuzinza kwe-dimensional, izinqubo zokukhiqiza zingase zibe nephutha futhi ziholele emikhiqizweni enesici.

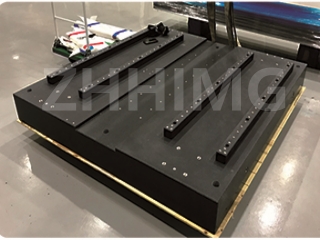

Ukuhlanganiswa kwe-Granite kusetshenziselwa njengenkundla yokukhiqiza i-semiconductor. Ihlinzeka ngendawo eyisicaba kakhulu futhi ezinzile evumela ukukhiqizwa okunembayo kwamasekhethi amancane, ayinkimbinkimbi adingekayo kumadivayisi we-semiconductor. Amapulatifomu okuhlanganisa i-Granite nawo asetshenziswa njengesisekelo sezinhlelo zamakhamera ezisetshenziselwa ukuhlola ingaphezulu lama-wafers we-semiconductor ngesikhathi sokukhiqiza.

Sekukonke, ukuhlanganiswa kwe-granite kwezinqubo zokukhiqiza i-semiconductor kuyingxenye ebalulekile ehlinzeka ngendawo ezinzile neyisicaba yezinqubo zokukhiqiza eziyinkimbinkimbi nezinembayo. Izakhiwo zayo ezihlukile zobulukhuni, ukuzinza okushisayo nobukhulu ziyenza ibe yinketho efanelekile ukusetshenziswa embonini ye-semiconductor. Ngokusetshenziswa kwayo, imboni ye-semiconductor ingaqhubeka nokukhiqiza amadivaysi e-semiconductor anembile futhi aphezulu anika amandla intuthuko yanamuhla yezobuchwepheshe.

Isikhathi sokuthumela: Dec-06-2023