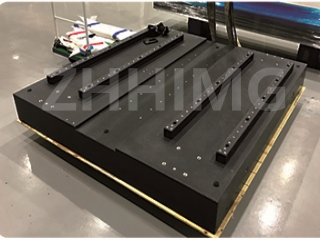

Ipuleti lobuso le-granite liyithuluzi lokunemba elenziwe nge-granite enobuningi obukhulu, elaziwa ngokuqina kwayo, ukuqina kwayo, kanye nokuba yisicaba. Lisetshenziswa kabanzi ekukhiqizeni, ekulinganiseni izilinganiso, nasekulawuleni ikhwalithi, lisebenza njengepulatifomu eyisisekelo yokuqinisekisa ukunemba ekulinganisweni nasekuhlolweni okubucayi. Nazi izinhlelo zokusebenza nezinzuzo zalo eziyinhloko:

1. Ukulinganisa Ngokunembile Nokulinganisa

Indima eyinhloko yepuleti lobuso le-granite ukuhlinzeka ngendawo yokubhekisela eyisicaba nezinzile yamathuluzi okulinganisa nezingxenye. Izakhiwo zayo ezingokwemvelo—njengokukhula okuphansi kokushisa, ukumelana nokugqwala, kanye nokuguquguquka okuncane ngokuhamba kwesikhathi—kwenza kube kuhle kakhulu ku:

Amathuluzi okulinganisa: Amathuluzi anjenge-micrometer, izinkomba zokudayela, kanye nemishini yokulinganisa eqondisanayo (ama-CMM) ayahlolwa futhi alinganiswe epuletini ukuqinisekisa ukuthi anikeza ukufundwa okunembile.

Ukuqinisekisa ubukhulu bezingxenye: Abakhiqizi babeka izingxenye ngqo epuletini ukuze bahlole ukuthi ziyisicaba, ziyisikwele, noma ziyafana besebenzisa ama-gauge noma ama-interferometer e-laser. Isibonelo, ezindiza, ama-turbine blades ayahlolwa ukuze kutholakale ukuphambuka okuncane kakhulu ezicacisweni zomklamo.

Ukunemba kwezinga le-Micrometer: Amapuleti ezinga eliphezulu (isb., Ibanga A) angafinyelela ukubekezelelana okuyisicaba okuqinile njengo-±0.00008 amasentimitha, okwenza kube yinto ebaluleke kakhulu ezimbonini ezifana nokukhiqiza ama-semiconductor, lapho ukunemba kubaluleke kakhulu.

2. Ukulawulwa Kwekhwalithi Nokuhlolwa

Emigqeni yokukhiqiza, amapuleti obuso be-granite asebenza njengezindawo zokulawula ikhwalithi ukuqinisekisa ukuthi izingxenye zihlangabezana nezindinganiso eziqinile:

Ukuhlolwa kokuphela kobuso: Izingxenye ezifakwe ngomshini (isb., amabhlogo enjini, amagiya) zifakwa epuletini ukuze kuhlolwe ubulukhuni bobuso noma ukungapheleli kusetshenziswa ama-profilometer noma ama-comparators optical.

Ukuqinisekiswa kokuhlanganiswa: Ngesikhathi sokuhlanganiswa kwezingxenye (isb., kumarobhothi noma kumadivayisi ezokwelapha), ipuleti liqinisekisa ukuthi izingxenye zibekwe kahle, okunciphisa amaphutha angaholela ekwehlulekeni komkhiqizo.

Ukuhambisana nezindinganiso: Izimboni ezilandela i-ISO, i-ASME, noma izindinganiso zezimoto (isb., i-IATF 16949) zithembele kumapuleti e-granite ukuqinisekisa izilinganiso nokugcina ukuhambisana nemithetho.

3. Ukusethwa Kwamathuluzi Nokulungiselelwa

Amapuleti obuso be-granite enza kube lula ukusethwa kwamathuluzi okusebenza kanye nezinto zokwakha:

Ukuqondanisa i-jig kanye ne-fixture: Ochwepheshe bemishini basebenzisa ipuleti ukubeka imishini yokubhoboza, yokugaya, noma yokugaya ngokunemba, ukuqinisekisa ubukhulu bezingxenye obuhambisanayo kuzo zonke izinqwaba.

Ukulinganiswa kwamathuluzi okusika: Amathuluzi afana nezigayo zokugcina noma ama-lathe bits ayalungiswa epuletini ukuze kufinyelelwe ama-engeli nokuphakama okufanele ngaphambi kokusebenzisa, okunciphisa imfucuza yezinto ezibonakalayo futhi kuthuthukiswe ukusebenza kahle.

4. Izicelo Zelebhu Nocwaningo

Ocwaningweni lwesayensi kanye nentuthuko (R&D), amapuleti e-granite ahlinzeka ngeplatifomu ezinzile yokuhlolwa okubucayi:

Ukusethwa kwe-optical kanye ne-laser: Emalabhorethri e-physics, amapuleti asekela ama-interferometer noma ama-spectrometer, lapho ukudlidliza noma izinguquko zokushisa kungaphazamisa imiphumela.

Ukuhlolwa kwezinto: Amasampula okuhlolwa kobulukhuni (isib. Ukuhlolwa kweRockwell noma kweVickers) abekwa epuletini ukuqinisekisa ukulayishwa okufanayo kanye nokuqoqwa kwedatha okunembile.

5. Izinzuzo Ngaphezu Kwamapuleti Ensimbi

Izakhiwo eziyingqayizivele ze-granite ziyenza ibe ngcono kakhulu kunezingcwecwe zensimbi noma zensimbi:

Ukuqina kokushisa: I-Granite imunca ukushisa kancane futhi ine-coefficient ephansi yokwanda kokushisa, okwenza ithembeke emazingeni okushisa ashintshashintshayo (isb., izindawo ze-车间).

Ayinamagnetic futhi ayimelani nokugqwala: Ngeke iphazamise amathuluzi anomagnetic noma yonakale uma ivezwa kumafutha, ama-coolant, noma umswakama.

Ubude Bokuphila: Ngokunakekelwa okufanele, ipuleti le-granite lingahlala amashumi eminyaka ngaphandle kokulahlekelwa yi-flat yalo, okunikeza inzuzo ephezulu ekutshalweni kwemali.

Isiphetho

Ipuleti elingaphezulu le-granite aliyona nje "i-flat slab" —liyisisekelo sokukhiqiza ngokunemba nokuqinisekisa ikhwalithi. Kungakhathaliseki ukuthi lisetshenziselwa ukulinganisa amathuluzi, ukuhlola izingxenye ezibalulekile, noma ukusekela izivivinyo eziyinkimbinkimbi, ukuzinza nokunemba kwalo kwenza lingabi khona esikhundleni salo ezimbonini lapho ngisho namaphutha amancane angaba nemiphumela ebalulekile. Ngokutshala imali epuletini le-granite elisezingeni eliphezulu, amabhizinisi angathuthukisa umkhiqizo, anciphise amaphutha, futhi alondoloze ukwethenjwa kwamakhasimende afuna ubuhle.

Isikhathi sokuthunyelwe: Meyi-23-2025