Izingxenye zokunemba kwe-granite: itshe eliyisisekelo lokukhiqiza ngokunemba kwezimboni

Emkhakheni wokukhiqiza ngokunemba embonini yanamuhla, izingxenye zokunemba kwe-granite sezibe yizinto eziyinhloko ezinhlelweni eziningi zokusebenzisa ngokunemba okuphezulu ngobuhle bazo obuyingqayizivele kanye nokusebenza okuhle kakhulu. Njengetshe eliqinile elenziwe ngokwemvelo, i-granite ayigcini nje ngokuba nezakhiwo ezinhle kakhulu zomzimba, kodwa futhi ikhombisa ukunemba okungavamile kanye nokuzinza ngesibusiso sobuchwepheshe bokukhanda ngokunemba.

Ukuhluka kwezingxenye zokunemba kwe-granite

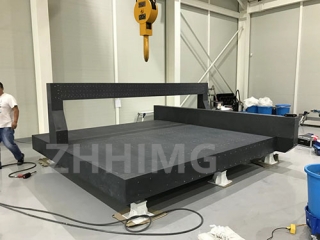

Ngamafuphi, izingxenye zokunemba kwe-granite ziwukusetshenziswa kwe-granite esezingeni eliphezulu ngokusebenzisa imishini enembile kakhulu kanye nokugaya kahle okwenziwe ngezingxenye. Azigcini nje ngokuzuza izinzuzo zemvelo ze-granite ngokwayo, njengokuqina, ukumelana nokuguguleka kanye nokumelana nokugqwala, kodwa futhi ziletha lezi zici ngokweqile ngobuchwepheshe bokukhiqiza obunembile. Yonke imininingwane yalezi zingxenye yaklanywa futhi yapholishwa ngokucophelela ukuqinisekisa ukuthi zibonisa ukuzinza nokunemba okungcono kakhulu ngesikhathi sokusetshenziswa.

Uhla olubanzi lwezinkambu zohlelo lokusebenza

Izingxenye ze-granite ezinembile zidlala indima ebalulekile emikhakheni eminingi yezimboni. Emkhakheni wokusebenza ngomshini, zivame ukusetshenziswa njengesisekelo kanye nomzila oqondisayo wamathuluzi omshini anembile kakhulu ukunikeza ukwesekwa okuzinzile kanye nesiqondiso esinembile senqubo yokusebenza ngomshini. Emkhakheni we-optics kanye nokulinganisa, izingxenye ze-granite ezinembile zilungele imishini yokulinganisa enembile kakhulu kanye nezinsimbi ze-optical ngenxa yokwanda kwazo okuphansi kokushisa kanye nokuqina okuphezulu. Ngaphezu kwalokho, emikhakheni yobuchwepheshe obuphezulu njengokukhiqiza izindiza kanye ne-semiconductor, izingxenye ze-granite ezinembile nazo zidlala indima engenakuphikwa.

Ukuqina kwezimfuneko zobuchwepheshe

Ukuze kuqinisekiswe ukusebenza kanye nekhwalithi yezingxenye zokunemba kwe-granite, inqubo yokukhiqiza kumele ilandele izidingo zobuchwepheshe eziqinile. Kusukela ekukhetheni izinto zokusetshenziswa kuya ekulawulweni kwenqubo yokucubungula kuya ekuhlolweni kwekhwalithi kokugcina, yonke isixhumanisi idinga ukusetshenziswa ngokucophelela futhi ihlolwe ngokucophelela. Isibonelo, ekukhetheni izinto zokusetshenziswa, kumele sikhethe i-granite esezingeni eliphezulu enobuthungo obufanayo, engenamifantu namaphutha; Enkambisweni yokugaya, kuyadingeka ukusebenzisa imishini yokugaya ye-CNC ethuthukisiwe kanye nobuchwepheshe bokugaya obuhle ukuqinisekisa ukuthi ukunemba kwejometri kanye nobukhali bomphezulu wengxenye kuhlangabezana nezidingo zomklamo; Ngokuphathelene nokuhlolwa kwekhwalithi, kuyadingeka ukusebenzisa imishini yokulinganisa enembile kakhulu kanye nezindinganiso zokuhlola eziqinile ukuqinisekisa ukuthi yonke ingxenye ihlangabezana nezidingo zekhwalithi.

Bheka esikhathini esizayo

Ngokuqhubeka kwesayensi nobuchwepheshe kanye nokuthuthuka okuqhubekayo kwezinga lokukhiqiza izimboni, amathuba okusetshenziswa kwezingxenye zokunemba kwe-granite azoba maningi. Ngokuvela okuqhubekayo kwezinto ezintsha kanye nokusungula izinto ezintsha okuqhubekayo kobuchwepheshe bokucubungula, ukusebenza kanye nekhwalithi yezingxenye zokunemba kwe-granite kuzoqhubeka nokuthuthuka. Ngesikhathi esifanayo, ngokuqwashisa okwandayo ngokuvikelwa kwemvelo, izidingo zabantu zokukhiqiza okuluhlaza kanye nentuthuko eqhubekayo ziya ngokuya ziphakama. Ngakho-ke, esikhathini esizayo, ukukhiqizwa kwezingxenye zokunemba kwe-granite kuzonaka kakhulu ukuvikelwa kwemvelo kanye nokusimama ukuze kuhlangatshezwane nesidingo semakethe semikhiqizo eluhlaza.

Ngamafuphi, izingxenye zokunemba kwe-granite, njengesisekelo sokukhiqiza ngokunemba kwezimboni, zizoqhubeka nokudlala indima ebalulekile esikhathini esizayo. Silangazelela ukukhuthazwa kwesayensi nobuchwepheshe kanye nezimboni, izingxenye zokunemba kwe-granite zingabonisa ukusebenza okuhle kakhulu kanye namathuba amaningi okusebenzisa.

Isikhathi sokuthunyelwe: Julayi-31-2024