Amathuluzi omshini we-CNC (computer numerical control) asetshenziswa ezimbonini ezahlukahlukene njengokukhiqiza, izindiza, izimoto, nokunye okuningi. Le mishini isetshenziselwa ukusika, ukubumba, nokuqopha izinto ezifana nensimbi, ipulasitiki, ukhuni, kanye ne-granite. Imishini ye-CNC idinga isisekelo esiqinile ukuze inikeze ukuzinza nokunemba, yingakho isisekelo se-granite sisetshenziswa njengengxenye ebalulekile kumathuluzi omshini we-CNC.

I-granite yaziwa ngokuzinza kwayo okuhle kakhulu kanye nokumelana nokuguquguquka, okwenza ibe yinto efanelekile yokusetshenziswa ekwakheni izisekelo zamathuluzi omshini. Ukuqina kwe-granite kuqinisekisa ukuthi ukunyakaza komshini ngesikhathi sokusika akuthinti ukunemba kokusikwa. Ubulukhuni obuphezulu kanye nesakhiwo esifanayo se-granite kuqinisekisa ukuphambuka okuphansi kanye nokuqina okuphezulu ngisho nangaphansi kwamazinga okushisa aphezulu kanye nengcindezi.

Ukusetshenziswa kwe-granite njengesisekelo nakho kunikeza izinga eliphezulu lokudambisa imishini ye-CNC. Izakhiwo zemvelo ze-granite ezibamba ukushaqeka zivumela imishini ukuthi isebenze ngesivinini esiphezulu ngaphandle kokugxuma noma ukuyeka ngokuzumayo, okuthuthukisa ukunemba nokunemba. Ukudlidliza okubangelwa inqubo yokusika kungabangela ukunyakaza okungafuneki emshinini, kodwa ngenxa yezici zokudambisa ze-granite, lokhu kudlidliza kuncishisiwe noma kuqedwe ngokuphelele.

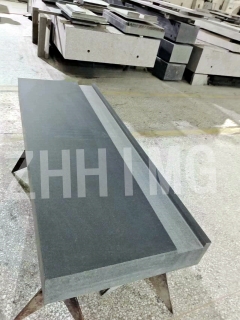

Ngaphezu kwalokho, isisekelo segranite senza amathuluzi omshini we-CNC abe nendawo yokusebenza enembile neqondile. Igranite inobulukhuni obuphansi kakhulu kanye nokuthamba okuphezulu, okusho ukuthi ubuso begranite buyisicaba ngaphakathi kwama-micron ambalwa. Uma umbhede womshini ufakwe kahle phezu kwesisekelo segranite, kuvumela umshini ukuthi ube nendawo yokusebenza eqinile nenembile. Lokhu kuqinisekisa ukuthi ithuluzi lomshini linquma ngokwezidingo eziqondile ezidingekayo.

Enye inzuzo yokusebenzisa i-granite esisekelweni semishini ye-CNC ukuthi ihlinzeka ngokumelana okuhle kakhulu namakhemikhali nokugqwala. I-granite imelana nama-asidi amaningi, izisekelo, kanye nezinyibilikisi, okwenza kube yinto efanelekile ukuyisebenzisa ezindaweni ezinzima. Lokhu kubalulekile ezimbonini lapho amakhemikhali namafutha evame ukusetshenziswa khona, njengoba kunciphisa amathuba okugqwala nokungcola ebusweni bethuluzi lomshini.

Ekuphetheni, isisekelo se-granite siyingxenye ebalulekile kumathuluzi omshini we-CNC. Siqinisekisa ukuzinza komshini ngesikhathi senqubo yokusika, sinciphisa ukudlidliza, sihlinzeka ngendawo yokusebenza elinganayo, futhi sithuthukisa ukunemba nokunemba. Izinzuzo zokusebenzisa i-granite njengesisekelo somshini ziyenza ithandwe ezimbonini ezahlukahlukene zokukhiqiza futhi zivumela amathuluzi omshini ukuthi asebenze ngamazinga aphezulu okusebenza kahle nokunemba.

Isikhathi sokuthunyelwe: Mashi-26-2024