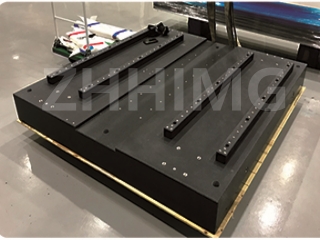

I-Granite yitshe lemvelo elinezindlela ezahlukene zobuhle nokusebenza, okuhlanganisa nokusetshenziswa kwalo ekukhiqizweni kwe-Coordinate Measuring Machines (CMM). Ama-CMM ayizinto zokulinganisa ezinembe kakhulu ezenzelwe ukunquma i-geometry kanye nobukhulu bento. Asetshenziswa ezimbonini ezahlukene, okuhlanganisa izindiza, izimoto, ubunjiniyela bemishini, nokuningi.

Ukubaluleka kokunemba ekulinganisweni kwe-CMM akunakuphikiswa, njengoba umehluko ngisho nowengxenye encane yesentimitha ungenza umehluko phakathi komkhiqizo osebenzayo nowomuntu onephutha. Ngakho-ke, izinto ezisetshenziswa ekwakheni i-CMM kumele zikwazi ukugcina isimo sazo futhi zihlale zizinzile ngokuhamba kwesikhathi ukuqinisekisa ukulinganisa okunembile nokungaguquguquki. Ngaphezu kwalokho, izinto ezisetshenziswayo kumele zikwazi ukumelana nezimo zokusebenza ezinzima.

Kulesi sihloko, sizoxoxa ngokuthi kungani i-granite iyinto efanelekile yokwakha i-CMM, nokuthi yiziphi izakhiwo ezenza ifanelekele umsebenzi.

1. Ukuqina:

Esinye sezimpawu ezibaluleke kakhulu ze-granite ukuqina kwayo. I-granite iyinto eqinile futhi engasebenzi kahle emelana kakhulu nokuguquguquka futhi ayinwebi noma inciphe ngokushintsha kwezinga lokushisa. Ngenxa yalokho, izingxenye ze-granite zinikeza ukuzinza okuhle kakhulu kobukhulu, okubalulekile ekufinyeleleni amazinga okunemba okuphezulu ekulinganisweni kwe-CMM.

2. Ukunciphisa ukudlidliza okuhle kakhulu:

I-granite inesakhiwo esiyingqayizivele esiyinika izakhiwo ezinhle kakhulu zokudambisa ukudlidliza. Ingamunca ukudlidliza futhi ikuhlukanise nepulatifomu yokulinganisa ukuze kutholakale imiphumela yokulinganisa ezinzile. Ukulawula ukudlidliza okuphumelelayo kubalulekile ekuqinisekiseni izilinganiso ze-CMM ezisezingeni eliphezulu, ikakhulukazi ezindaweni ezinomsindo. Izakhiwo zokudambisa ukudlidliza ze-granite ziyivumela ukuthi ihlunge ukuphazamiseka okungafuneki futhi iqinisekise imiphumela ethembekile.

3. Ukumelana nokuguga:

I-Granite iyinto eqinile kakhulu engakwazi ukumelana nokuguguleka okuhambisana nokusetshenziswa okuqhubekayo ezindaweni zezimboni. Imelana nokuklwebheka, ukuqhekeka, nokugqwala, okwenza ibe yinto efanelekile yezingxenye ze-CMM ezihlangana nezingxenye ezihambayo kanye nezinto ezihudulayo.

4. Ukuqina kokushisa:

I-Granite ine-coefficient ephansi yokwanda kokushisa, okusho ukuthi ayikhuli noma ayinciphisi kakhulu ngokushintsha kwezinga lokushisa. Ngenxa yalokho, ingagcina isimo sayo, ngisho noma ibhekene nokushintshashintsha kwezinga lokushisa, okuvumela ama-CMM ukuthi akhiqize imiphumela enembile emazingeni okushisa ahlukahlukene okusebenza.

5. Ukukwazi ukusebenza:

I-Granite iyinto enzima futhi eyinselele ukusebenza ngayo. Idinga ubuchwepheshe obuthuthukisiwe kanye nemishini ekhethekile ukuze ilolongwe futhi iqedwe ngendlela efanele. Noma kunjalo, ukusebenza kwayo kahle kuvumela ukucutshungulwa okunembile kwezingxenye ze-granite, okuholela emikhiqizweni eqediwe esezingeni eliphezulu.

Ekuphetheni, i-granite iyinto efanelekile yokwakha i-CMM ngenxa yokuqina kwayo okuphezulu, izakhiwo zokudambisa ukudlidliza, ukumelana nokuguguleka, ukuqina kokushisa, kanye nokusebenza kahle kwemishini. Ama-granite CMM akhiwe ukuze amelane nezimo zokusebenza ezinzima futhi anikeze izilinganiso ezinembile kakhulu. Ngaphezu kwalokho, anikeza impilo yesevisi ende, ukusebenza ngaphandle kokugcinwa, kanye nokuqina, okwenza kube utshalomali oluhlakaniphile nolungabizi kakhulu ezimbonini eziningi ezahlukene.

Isikhathi sokuthunyelwe: Ephreli-02-2024