Izingxenye zokunemba kwe-granite zidlala indima ebalulekile ekulinganisweni kwemishini ye-VMM (Vision Measuring Machine). Imishini ye-VMM isetshenziselwa ukulinganisa okunembile nokunembile kwezingxenye ezahlukahlukene ezimbonini ezifana nezimoto, izindiza, kanye nokukhiqiza. Ukunemba nokuthembeka kwalezi zilinganiso kuncike kakhulu ekuzinzeni nasekuqondeni kwezingxenye zomshini, ikakhulukazi izingxenye zokunemba kwe-granite.

I-Granite iyindlela ethandwayo yokukhetha izingxenye ezinembile emishinini ye-VMM ngenxa yokuqina kwayo okumangalisayo, ukuqina, kanye nokumelana nokuguguleka nokugqwala. Lezi zakhiwo zenza kube yinto efanelekile yokuqinisekisa ukunemba nokuthembeka kwezilinganiso ezithathwa yimishini ye-VMM. Ukusetshenziswa kwezingxenye ezinembile ze-granite emishinini ye-VMM kusiza ukunciphisa imiphumela yezici zangaphandle njengokushintshashintsha kwezinga lokushisa nokudlidliza, okungalimaza ukunemba kwezilinganiso.

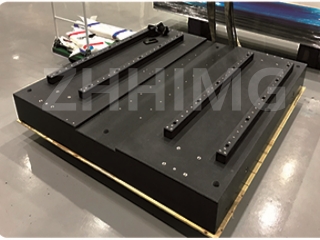

Izingxenye zokunemba kwe-granite emishinini ye-VMM, njengezisekelo ze-granite kanye nezigaba ze-granite, zinikeza isisekelo esiqinile nesiqinile sezingxenye ezihambayo zomshini kanye nezinhlelo zokulinganisa. Lokhu kuzinza kubalulekile ekufinyeleleni izilinganiso ezinembile neziphindaphindwayo, ikakhulukazi lapho kubhekene nokubekezelelana okuqinile kanye namajiyometri ayinkimbinkimbi. Ukuzinza okuphezulu kwe-granite kuqinisekisa ukuthi umshini ugcina ukulinganiswa kwawo ngokuhamba kwesikhathi, kunciphisa isidingo sokulungiswa kabusha nokugcinwa njalo.

Ngaphezu kwalokho, i-coefficient yokukhulisa ukushisa ephansi ye-granite isiza ukunciphisa imiphumela yokushintshashintsha kwezinga lokushisa ekunembeni komshini, okwenza ufanelekele ukusetshenziswa ezindaweni ezahlukahlukene zezimboni. Izakhiwo ezingokwemvelo zokudambisa i-granite nazo zinegalelo ekunciphiseni umthelela wokudlidliza nokuphazamiseka kwangaphandle, okuthuthukisa kakhulu ukunemba kokulinganisa.

Ekuphetheni, izingxenye zokunemba kwe-granite zidlala indima ebalulekile ekulinganisweni kwemishini ye-VMM ngokunikeza ukuzinza, ukuqina, kanye nokunemba okudingekayo ukuze kulinganiswe kahle. Ukusetshenziswa kwazo kuqinisekisa ukuthi imishini ye-VMM ingaletha njalo idatha yokulinganisa ethembekile nekhwalithi ephezulu, okwenza ibe amathuluzi abalulekile ezimbonini ezahlukahlukene lapho ukunemba nokunemba kubaluleke kakhulu. Njengoba ubuchwepheshe buqhubeka nokuthuthuka, isidingo sezingxenye zokunemba kwe-granite emishinini ye-VMM kulindeleke ukuthi sikhule, okugcizelela kakhulu ukubaluleka kwazo emkhakheni we-metrology kanye nokulawulwa kwekhwalithi.

Isikhathi sokuthunyelwe: Julayi-02-2024