I-CMM (Umshini Wokulinganisa Ohlanganisayo) iyithuluzi lokulinganisa elinembile kakhulu nelinembile elivame ukusetshenziswa ezimbonini ezifana nezindiza, izimoto, kanye nezokwelapha. Nakuba kunezinhlobo ezahlukene zama-CMM, enye yezinto ezisetshenziswa kakhulu esisekelo se-CMM yi-granite. I-Granite iyindlela enhle kakhulu yokukhetha izinto njengoba iqinile, izinzile, futhi inikeza indawo efanayo ukuze i-CMM ilinganise kuyo.

Kodwa-ke, ukufaka i-CMM esisekelweni se-granite akwanele ukuqinisekisa ukunemba kokulinganisa okuhle kakhulu. Kunezici eziningana okudingeka zicatshangelwe ukuqinisekisa ukuthi i-CMM isebenza kahle kakhulu. Kulesi sihloko, sizoxoxa ngezinto ezibalulekile okudingeka zicatshangelwe lapho kufakwa i-CMM esisekelweni se-granite ukuze kuthuthukiswe ukunemba kokulinganisa.

1. Ukulawula Izinga Lokushisa

Ukulawulwa kwezinga lokushisa kungenye yezinto ezibaluleke kakhulu okufanele zicatshangelwe. I-Granite ine-coefficient ephezulu yokwanda kokushisa, okusho ukuthi ingakhula futhi inciphe ngokushintsha kwezinga lokushisa. Ngakho-ke, kubalulekile ukugcina izinga lokushisa lizinzile ekamelweni lapho i-CMM ikhona khona. Ngisho nokushintshashintsha kwezinga lokushisa okuncane kungabangela ukuthi i-granite ikhule noma inciphe, okuzoholela emaphutheni okulinganisa. Ukuze kugwenywe lokhu, igumbi kufanele lilawulwe izinga lokushisa, futhi i-CMM kufanele ivalwe kunoma yikuphi ukushintshashintsha kwezinga lokushisa kwangaphandle.

2. Ukulawula Ukudlidliza

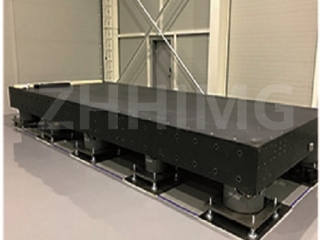

Ukulawulwa kokudlidliza kungenye into ebalulekile ukuqinisekisa ukunemba kokulinganisa. I-Granite iyi-damper yokudlidliza enhle kakhulu, kodwa isasengozini yokudlidliza okuvela emithonjeni yangaphandle njengeminye imishini, imigwaqo eseduze, noma ngisho nokuhamba ngezinyawo. Lokhu kudlidliza kungabangela ukuthi isisekelo se-granite sihambe, okuholela emaphutheni okulinganisa. Ukuze kuncishiswe umthelela wokudlidliza kwangaphandle, i-CMM kufanele ibekwe endaweni engenazo izidlidliza, futhi noma yimiphi imithombo yokudlidliza yangaphandle kufanele ihlukaniswe noma ivikelwe.

3. Ukulinganisa

Ukuba nesisekelo se-granite esisezingeni elifanele kubalulekile ekulinganisweni okunembile. Uma ufaka i-CMM esisekelweni se-granite, isisekelo kufanele silinganiswe ngokunemba okuphezulu. Inqubo yokulinganisa ibaluleke kakhulu ngoba ngisho nokuphambuka okuncane kungabangela amaphutha okulinganisa. Ngakho-ke, kunconywa ukuthi ukulinganisa kwenziwe kusetshenziswa amazinga omoya okunemba futhi kuqinisekiswe kusetshenziswa i-CMM uqobo.

4. Ukufakwa

Okunye okubalulekile okufanele kucatshangelwe ukufakwa kwe-CMM esisekelweni se-granite. I-CMM kufanele ifakwe ngokucophelela okukhulu nangokunemba, ukuze kugwenywe noma yikuphi ukungalungi noma ukulimala. Inqubo yokufaka kufanele yenziwe ochwepheshe abaqeqeshiwe nabanolwazi ukuqinisekisa ukuthi i-CMM ifakwe kahle.

5. Ukulungiswa

Ukugcina i-CMM kubalulekile ukuqinisekisa ukusebenza kahle kanye nokunemba kokulinganisa. Ukugcinwa njalo komshini kanye nesisekelo se-granite kuzoqinisekisa ukuthi i-CMM isebenza kahle kakhulu. Izingxenye ezigugile noma ezonakele zidinga ukushintshwa ngokushesha, futhi isisekelo se-granite sidinga ukuhlolwa njalo. Ukuhlolwa njalo kanye nezinqubo zokulungisa kungavimbela isidingo sokulungiswa okubizayo futhi kunciphise umthelela ekunembeni kokulinganisa.

Isiphetho

Ngamafuphi, isisekelo se-granite se-CMM sibalulekile ekulinganisweni ngokunemba. Kodwa-ke, ukufakwa kwe-CMM esisekelweni se-granite akwanele ukuqinisekisa ukunemba kokulinganisa okuhle. Kunezinto eziningana ezibalulekile okudingeka zicatshangelwe, okuhlanganisa ukulawula izinga lokushisa, ukulawula ukudlidliza, ukulinganisa, ukufakwa, kanye nokugcinwa. Ngokucabangela lezi zinto, abakhiqizi bangaqinisekisa ukuthi ama-CMM abo asebenza kahle kakhulu, futhi izilinganiso ezinembile zithathwa njalo.

Isikhathi sokuthunyelwe: Ephreli-01-2024