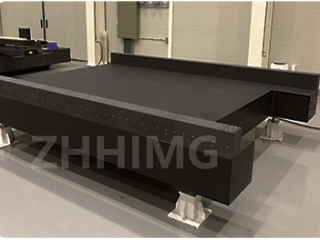

Umshini wokulinganisa i-bridge coordinate uwumshini obucayi kakhulu osetshenziswa embonini yokukhiqiza nokuhlola ukuqinisekisa ukuthi imikhiqizo ihlangabezana nezimfuneko ezithile. Lolu hlobo lomshini luvame ukuba nombhede we-granite osebenza njengendawo yokubhekisela ekusebenzeni komshini. Umbhede we-granite uyingxenye ebalulekile yemishini futhi udinga ukuphathwa ngokucophelela nokuqapha ukuze kugwenywe umonakalo. Kulesi sihloko, sizoxoxa ngendlela yokusebenzisa umshini wokulinganisa i-bridge coordinate ukuze kugwenywe ukulimaza umbhede we-granite.

1. Gcina ihlanzekile

Isinyathelo sokuqala sokuvimbela umonakalo embhedeni we-granite ukuwugcina uhlanzekile ngaso sonke isikhathi. Hlanza umbhede ngaphambi nangemva kokusebenzisa, usebenzisa izinto zokuhlanza ezinconywayo kuphela. Gwema ukusebenzisa izinto ezihudulayo ezingase ziklwebhe futhi zonakalise ubuso be-granite. Inqubo yokuhlanza kufanele ibe lula futhi iqonde, usebenzisa indwangu ethambile kanye nensipho ethambile.

2. Gwema umthelela

Gwema ukushaya umbhede wegranite nganoma yiziphi izinto noma amathuluzi. Igranite iyinto eqinile, kodwa ivame ukuqhekeka nokuqhekeka uma ishaywa ngamathuluzi asindayo. Qinisekisa ukuthi umbhede awunazo izinto ezingadala umonakalo, futhi uqaphele lapho ulayisha futhi uthulula izingxenye embhedeni.

3. Ungagcwali ngokweqile

Umshini wokulinganisa ibhuloho unomkhawulo wesisindo, futhi kubalulekile ukungawugcwalisi umshini ngokweqile. Ukulayisha umshini ngokweqile kuzobangela ingcindezi embhedeni wegranite, okungaholela ekulimaleni. Qiniseka ukuthi uhlola umthamo wesisindo somshini ngaphambi kokulayisha izingxenye.

4. Linganisa umbhede

Ukuze kuqinisekiswe ukuthi izilinganiso zinembile, umbhede wegranite kumele ube sezingeni elifanele. Hlola izinga lombhede njalo bese uwulungisa njengoba kudingeka. Uma umbhede ungalingani, kuzoholela ekulinganisweni okunganembile, okungabangela amaphutha futhi kuholele ekulungisweni kabusha.

5. Ukulawulwa kwezinga lokushisa

I-granite iyazwela ezinguqukweni zokushisa, futhi inganda noma inciphe kuye ngokushisa. Qinisekisa ukuthi izinga lokushisa ekamelweni lizinzile ukuze ugweme noma yiziphi izinguquko ezibalulekile zokushisa ezingaholela ekugobekeni noma ekuqhekekeni kombhede we-granite. Hlola izinga lokushisa njalo bese ulilungisa uma kudingeka.

6. Sebenzisa umshini ngendlela efanele

Ukusebenza komshini wokulinganisa ibhuloho kubalulekile ekugwemeni umonakalo embhedeni wegranite. Qiniseka ukuthi ulandela iziqondiso zomenzi lapho usebenzisa umshini. Iziqondiso zizochaza izinyathelo okufanele zilandelwe lapho ulayisha, ukhulula, futhi usebenzisa umshini. Umshini akufanele uphoqelelwe, futhi noma yiziphi izinkinga kufanele zibikwe ngokushesha.

Ekuphetheni, umbhede we-granite uyingxenye ebalulekile yomshini wokulinganisa i-bridge coordinate, futhi noma yimuphi umonakalo ungaholela ekulinganisweni okunganembile. Ngakho-ke, kubalulekile ukuthatha izinyathelo zokuphepha ezidingekayo lapho usebenzisa lo mshini ukuze ugweme umonakalo. Ngokulandela iziqondiso ezichazwe ngenhla, umsebenzisi angasiza ekuvikeleni umshini futhi aqinisekise ukulinganiswa okunembile, okuholela emikhiqizweni esezingeni eliphezulu.

Isikhathi sokuthunyelwe: Ephreli-17-2024