Eminyakeni yamuva nje, isidingo sezisekelo zomshini ezizinzile, ezingamelani nokushisa, nezincibilikisayo sikhule ngokushesha kuzo zonke izimboni zokunemba zomhlaba wonke. Njengoba imishini ye-semiconductor, izinhlelo ze-optical metrology, imishini yokulinganisa edidiyelwe, kanye nokwenza izinto ngokuzenzakalela okuthuthukisiwe kuqhubeka nokufaka ukunemba ebangeni le-sub-micron, isakhiwo esisekelayo ngaphansi komshini siba sibaluleke njengomshini uqobo. Yilapho isisekelo se-precision granite pedestal sivele khona njengezinto eziyisisekelo ezikhethwayo zonjiniyela nabakhiqizi bemishini abangakwazi ukubekezelela ukukhukhuleka kobukhulu noma ukungazinzi kwesakhiwo.

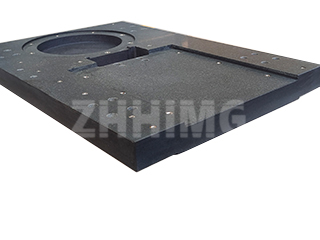

Isisekelo sesisekelo se-granite emnyama asisabonwa njengebhulokhi yetshe elingasebenzi. Sesibe yingxenye eyakhiwe ngendlela yobunjiniyela eyenzelwe ukuletha ukuzinza kwesikhathi eside, ukuqina okuphezulu, kanye nokumelana okuhle kakhulu nokuguguleka. I-granite etholakala kulezi zisekelo kumele ihlangabezane nezindinganiso zokukhetha eziqinile, futhi kwa-ZHHIMG, izinto ezisetshenziswayo yi-UNPARALLELED® Black Granite, eyaziwa ngokuxinana kwayo okungavamile, ukuvuleka okuphansi, kanye nokusabela okuzinzile kokushisa. Lokhu kwaziswa kunikeza inzuzo enkulu ngaphezu kwama-granite amaningi aseYurophu naseMelika, ikakhulukazi ezindaweni lapho ngisho nokushintshashintsha okuncane kokushisa kungathinta ukulinganisa noma ukunemba komshini.

Ukwethulwa kwendinganiso yesisekelo segranite ye-Grade00 kuye kwakha okunye okulindelwe kokumetrology kanye nokuzinza kwemishini. I-Grade00 yaziwa kabanzi njengezinga lokunemba eliphakeme kakhulu embonini, inikeza ukubekezelelana okuqinile kakhulu okusicaba okuqinisekisa ukusebenza okungenamaphutha lapho kusekelwa ukuhlanganiswa kokunemba. Lapho isisekelo sokunemba segranite emnyama senziwe sakhiwe safinyelela emazingeni e-Grade00, sinikeza isisekelo esidingekayo semisebenzi yokunemba okuphezulu lapho ukuphindaphindeka kanye nokuthembeka kwesikhathi eside kungaxoxiswana ngakho.

Abakhiqizi bemishini abaningi baphendukela ezisekelweni ze-granite pedestal ngoba izinto ezihlukile azikwazi ukulingana nokusebenza kwe-granite. Izisekelo zensimbi, isibonelo, zihlushwa ukwanda kokushisa kanye nokucindezeleka kwangaphakathi okuguqukayo ngokuhamba kwesikhathi. Izisekelo zekhonkrithi ye-polymer ziletha ukumanzisa okuhle kodwa azinawo ukumelana nokuguguleka kwesikhathi eside okudingekayo ezindaweni zezimboni ezisebenza kakhulu. I-granite ixazulula lezi zinkinga ngokuzinza kwayo kwemvelo kanye nekhono layo lokugcina ukunemba kwesakhiwo amashumi eminyaka ngaphandle kokuguquka. Ukumelana kwayo nokugqwala kanye nomswakama kuthuthukisa kakhulu ukufaneleka kwayo kuma-laboratory, amakamelo okuhlanza, kanye nezitezi zokukhiqiza ezidlidliza kakhulu.

Njengoba imishini iba yinkimbinkimbi kakhulu, izisekelo zezisekelo azisezona izakhiwo ezilula ze-monolithic. Imiklamo yesisekelo sezisekelo zezisekelo ze-granite ezinembile zanamuhla ivame ukuhlanganisa ama-inserts, ama-threaded bushings, ama-T-slots, ama-air-bearing interfaces, izinhlelo zokuhlukanisa ukudlidliza, iziteshi zokuhambisa izintambo, kanye nezici zokwenza ngokwezifiso. Lezi zengezo zivumela isisekelo se-granite ukuthi sisebenze njengokusekelwa kwesakhiwo kanye neplatifomu esebenzayo ehlanganisiwe. Ithimba lobunjiniyela le-ZHHIMG lisebenzisana eduze namakhasimende ukwenza ngezifiso isisekelo ngasinye ukuze sivumelane kahle nomklamo womshini, ukuqinisekisa ukusebenza kahle komshini kanye nokulula kwe-ergonomic.

Abakhiqizi ku-semiconductor lithography, ukuhlolwa kwe-optical, amarobhothi athuthukile, ukuhlolwa kwezingxenye zezindiza, kanye nokuhlanganiswa kwe-micro-mechanical bamukela kakhulu izisekelo ze-granite emnyama ngoba izinto zithuthukisa ukuthembeka kokulinganisa kanye nokuqina kokukhiqiza. Amandla okugcina ukuthamba kwezinga elincane kanye nobuqotho besakhiwo ngaphansi komthwalo oqhubekayo enza i-granite ibe yinto ebalulekile ekusebenzeni lapho i-micron eyodwa yokukhukhuleka ingafaka engcupheni inqubo yonke yokukhiqiza. Izici zayo ezingezona ezikagesi neziphansi zokuqhuba ziyenza ifaneleke kakhulu ezindaweni lapho ukuphazamiseka kwe-electromagnetic noma ukuphambuka kokushisa kufanele kuncishiswe.

Ukugcinwa kulula futhi akudingi amakhemikhali noma izembozo ezikhethekile. Isisekelo segranite se-Grade00 sidinga ukuhlanzwa njalo ngensipho encane kanye nokuhlolwa njalo kwezindawo zokufaka nezesekeli. Ngenxa yokuthi igranite ayigqwali, ayigobi, noma ayigugi njengensimbi, izindleko zokugcinwa kwayo empilweni yayo yonke ziphansi kakhulu. Uma indawo yokusebenza iguga eminyakeni eminingi yokusetshenziswa, ingaphinde ihlanganiswe ochwepheshe ukuze ibuyisele ukuthamba kwayo kwasekuqaleni—inzuzo enkulu kunezakhiwo zensimbi ezingadinga ukushintshwa ngokuphelele.

Intuthuko esheshayo yobunjiniyela bokunemba yenze isisekelo somshini ngamunye saba sibaluleke kakhulu kunanini ngaphambili. Isisekelo sokunemba se-granite emnyama esakhiwe ngokucophelela sinikeza ukusebenza okuthonya ngqo ikhwalithi yomshini, ukunemba kokulinganisa, kanye nokuthembeka komkhiqizo wokugcina. Njengoba izimboni zamukela izidingo zokunemba okuphezulu, isisekelo se-granite se-precision siba ngcono kakhulu kunokuba sibe yingxenye yokuzikhethela. Izinzuzo zaso zokusebenza zihumusha ngqo ekuvuneni okuphezulu, ukuzinza okungcono, kanye nokuzethemba okukhulu kwamakhasimende.

I-ZHHIMG iyaqhubeka nokusekela izinkampani emhlabeni wonke ngezisekelo ze-granite ezenziwe ngokwezifiso ezenzelwe ukunemba kwesikhathi eside. Isekelwa yizitifiketi ze-ISO, amakhono okukhiqiza athuthukile, kanye namashumi eminyaka yesipiliyoni emkhakheni wokunemba okuphezulu, inkampani inikeza izixazululo ezithenjwa ngabaholi bomhlaba wonke ku-semiconductor, metrology, ezenzakalelayo, izindiza, kanye nocwaningo lwesayensi. Njengoba izidingo zokunemba zikhuphuka, i-granite izoqhubeka nokudlala indima ebalulekile ekwakheni isizukulwane esilandelayo sezinhlelo zezimboni ezisebenza kahle kakhulu.

Isikhathi sokuthunyelwe: Disemba-02-2025