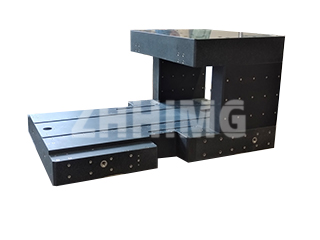

Ezweni lokukhiqiza okunembile kakhulu kanye ne-metrology, isisekelo somshini we-granite singaphezu nje kwetshe elilula—yinto eyisisekelo enquma uphahla lokusebenza kwesistimu yonke. Kwa-ZHONGHUI Group (ZHHIMG®), siyaqonda ukuthi ubukhulu bangaphandle balezi zisekelo ze-granite ezinembile, ezisetshenziswa kukho konke kusukela kumishini ye-semiconductor ethuthukisiwe kuya kumathuluzi okukhanya anesinqumo esiphezulu, yizincazelo ezingaxoxiswani. Ziyisihluthulelo sokuzinza, ukunemba, kanye nokuhlanganiswa okungenamthungo.

Le ngxoxo igxila ezidingweni eziqinile zobukhulu ezichaza isisekelo se-granite sezinga lomhlaba, okuqinisekisa indima yaso njengomgcini ofanele kakhulu wezinto ezidingwa kakhulu zemishini nezokukhanya.

Isici Esichazayo: Ukunemba Okukhulu Kobukhulu

Isidingo esiyinhloko sanoma iyiphi ingxenye ye-granite ukunemba kobukhulu, okudlulela kude kakhulu kubude obuyisisekelo, ububanzi, nokuphakama. Ukubekezelelana kwalezi zilinganiso eziyisisekelo kumele kunamathele ngokuqinile ezicacisweni zomklamo, kuqinisekiswe ukulingana okuphelele ngesikhathi senqubo yokuhlanganisa evame ukuba yinkimbinkimbi. Emishinini esebenza enqenqemeni lobuchwepheshe obuphambili, lokhu kubekezelelana kuqinile kakhulu kunezindinganiso zobunjiniyela ezijwayelekile, kudinga ukulingana okusondelene kakhulu phakathi kwesisekelo se-granite kanye nezixhumi zemishini yokuhlanganisa.

Okubaluleke kakhulu, ukunemba kwejiyometri—ubudlelwano phakathi kobuso besisekelo—kubaluleke kakhulu. Ukuthamba kanye nokulingana kwezindawo eziphezulu nezingezansi zegranite kubalulekile ekufakweni okungenangcindezi nokugcina ukulingana kwemishini. Ngaphezu kwalokho, lapho kuhileleke khona izigaba eziqondile noma izinhlelo ze-multi-axis, ukuma kanye nokuqina kwezici zokufaka kumele kuqinisekiswe ngokulinganisa okucophelelayo, okunesinqumo esiphezulu. Ukwehluleka kulezi jiyometri kuhumusha ngqo ekunembeni kokusebenza okuphazamisekile, okungamukeleki nje kubunjiniyela bokunemba.

Ukungaguquguquki Nokuzinza: Isisekelo Esakhelwe Ukuhlala Isikhathi Eside

Isisekelo se-granite esithembekile kumele sibonise ukuhambisana kwesimo okungavamile kanye nokuqina kobukhulu ngokuhamba kwesikhathi. Nakuba izisekelo zivame ukuba ne-geometry eqondile engunxande noma eyindilinga ukuze kube lula ukufaka, ukugcina ubukhulu obufanayo kuzo zonke izinqwaba kubalulekile ekukhiqizweni nasekuqalisweni kwemishini okulula.

Lokhu kuzinza kuyisici esibalulekile se-ZHHIMG® black granite, ezuza ekucindezelekeni kwayo kwangaphakathi okuphansi ngokwemvelo. Ngokugaya ngokunembile, ukugoqa, kanye nenqubo yokukhiqiza ngokucophelela eyenziwa ngaphakathi kwendawo yethu yokushisa nomswakama engaguquki, sinciphisa amathuba okukhukhuleka kobukhulu obubangelwa ukushintshashintsha okuncane kokushisa noma komswakama. Lokhu kuzinza kwesikhathi eside kuqinisekisa ukuthi isisekelo sigcina ukunemba kwaso kokuqala—kanjalo nokusebenza kwemishini—kuyo yonke impilo yaso yokusebenza.

Ukuhlanganiswa Okungenamthungo: Ukuzivumelanisa Nezimo Nokuhambisana

Isisekelo se-granite akuyona iyunithi ehlukanisiwe; siyisixhumi esisebenzayo ngaphakathi kwesistimu eyinkimbinkimbi. Ngakho-ke, ukwakheka kwaso kobukhulu kumele kubeke phambili ukuhambisana kwesixhumi semishini. Izimbobo zokufaka, imiphetho yokubhekisela enembile, kanye nezikhala zokubeka ezikhethekile kumele zivumelane kahle nezidingo zokufakwa kwemishini. Kwa-ZHHIMG®, lokhu kusho ubunjiniyela bezindinganiso ezithile, kungakhathaliseki ukuthi kuhilela ukuhlanganiswa namapulatifomu e-linear motor, ama-air bearings, noma amathuluzi e-metrology akhethekile.

Ngaphezu kwalokho, isisekelo kumele sihambisane nokuhambisana kwaso nendawo esisebenza kuyo. Ekusetshenzisweni kwamagumbi okuhlanza, amakamelo okuhlanza, noma ezindaweni ezivezwe kungcolisi, isimo se-granite esingagqwali, kuhlanganiswe nezici ezifanele zobukhulu bokuvala nokufaka, kuqinisekisa ukuzinza okuqhubekayo kanye nokusetshenziswa ngaphandle kokuwohloka.

Ukuklama Isisekelo Esifanele: Izinto Ezibalulekile Nezomnotho

Umklamo wokugcina onobukhulu besisekelo se-granite esenziwe ngokwezifiso uyisenzo sokulinganisela isidingo sobuchwepheshe, izinto ezisebenzisekayo, kanye nokusebenza kahle kwezindleko.

Okokuqala, isisindo nobukhulu bemishini kuyizinto eziyisisekelo. Imishini esindayo noma enkulu idinga isisekelo segranite esinobukhulu obukhulu kanye nobukhulu obulinganayo ukuze kufezwe ukuqina nokusekelwa okwanele. Ubukhulu besisekelo kumele futhi bucatshangelwe ngaphakathi kwemingcele yesikhala sendawo yokusebenza yomsebenzisi wokugcina kanye nokufinyelela kokusebenza.

Okwesibili, ukulula kokuthutha nokufakwa kuyimingcele engokoqobo ethinta umklamo. Ngenkathi amakhono ethu okukhiqiza evumela izingxenye ze-monolithic ezingafika kumathani ayi-100, usayizi wokugcina kumele ube lula ukuphatha kahle, ukuthunyelwa, kanye nokubekwa endaweni. Umklamo ocatshangelwe kahle uhlanganisa ukucatshangelwa kwezindawo zokuphakamisa kanye nezindlela zokulungisa ezinokwethenjelwa.

Okokugcina, yize ukunemba kuyisibopho sethu esiyinhloko, ukusebenza kahle kwezindleko kusalokhu kuyinto okufanele siyicabangele. Ngokwenza ngcono ukwakheka kobukhulu kanye nokusebenzisa amasu okucubungula asebenzayo, amakhulu—njengalawo asetshenziswa ezindaweni zethu—sinciphisa imfucuza yokukhiqiza kanye nobunzima. Lokhu kuthuthukisa kunikeza umkhiqizo onenani eliphezulu ohlangabezana nezidingo zokunemba ezidinga kakhulu ngenkathi kuqinisekiswa imbuyiselo enhle kakhulu ekutshalweni kwezimali komkhiqizi wemishini.

Ekuphetheni, ubuqotho obukhulu bezisekelo ze-granite ezinembile buyimfuneko enezici eziningi ebalulekile ekuzinzeni nasekusebenzeni kwesikhathi eside kwemishini yobuchwepheshe obuphezulu. Kwa-ZHHIMG®, sihlanganisa isayensi yezinto ezibonakalayo zezinga lomhlaba kanye nokunemba kokukhiqiza okuthuthukisiwe ukuze sinikeze izisekelo ezingahlangabezani nje kuphela nezimfuneko, kodwa futhi ezichaza kabusha okungenzeka.

Isikhathi sokuthunyelwe: Okthoba-30-2025