Embonini yokucubungula ingilazi, ukunemba nokuqina kwemishini yokusika ingilazi kunquma ngqo ikhwalithi yomkhiqizo kanye nokusebenza kahle kokukhiqiza. Izisekelo zegranite zidlala indima ebalulekile emishinini yokusika ingilazi, ikakhulukazi ngenxa yezici zazo ezihlukile neziphakeme.

Ukuqina okuvelele kuqinisekisa ukunemba kokusika

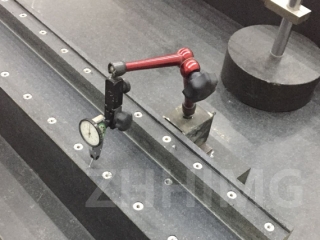

Ukusikwa kwengilazi kunezidingo zokunemba okuphezulu kakhulu. Ngisho nokuphambuka okuncane kakhulu kungaholela ekukhuculweni komkhiqizo. Isisekelo se-granite sakhiwa isikhathi eside se-geological, sinesakhiwo sangaphakathi esiminyene nesifanayo. I-coefficient yayo yokwanda kokushisa iphansi kakhulu, kuphela (4-8) ×10⁻⁶/℃, futhi usayizi wayo awushintshi kangako lapho izinga lokushisa lishintsha. Ngesikhathi senqubo yokusikwa kwengilazi, ukushisa okukhiqizwa ukusebenza kwemishini kanye nokushintshashintsha kwezinga lokushisa endaweni yokusebenza ngeke kubangele ukuguqulwa okusobala kokushisa kwesisekelo se-granite. Ingahlala inikeza ukwesekwa okuzinzile nokuthembekile kwedivayisi yokusika, iqinisekisa indawo eqondile yethuluzi lokusika noma umsebe we-laser. Ingilazi eqoshiwe inemiphetho ecocekile kanye nobukhulu obunembile, ithuthukisa kakhulu isivuno semikhiqizo.

Ukuqina okuqinile kumelana nokushaywa ngamandla angaphandle

Uma imishini yokusika ingilazi isebenza, ukuxhumana phakathi kwezingxenye zokusika nengilazi kuzokhiqiza amandla athile okushaya, futhi ngesikhathi esifanayo, ukunyakaza kwemishini ngokwayo kuzobangela nokudlidliza. I-Granite iqinile ekubunjweni futhi inokuqina okuhle kakhulu. Ubulukhuni bayo bungafinyelela ku-6-7 esikalini se-Mohs futhi inamandla aphezulu okucindezela. Lokhu kwenza isisekelo se-granite sikwazi ukumelana kalula namandla ahlukahlukene angaphandle ngesikhathi senqubo yokusika futhi cishe akunakwenzeka ukuthi sonakale noma sonakale. Uma kuqhathaniswa nezinye izisekelo zensimbi ezingase zishintshe ukukhathala ngaphansi kwamandla angaphandle esikhathi eside navamile, izisekelo ze-granite, ngokuqina kwazo okuqinile, zingahlala zigcina isakhiwo esizinzile, ziqinisekisa ukusebenza okuzinzile kwesikhathi eside kwemishini nokunciphisa ukugcinwa kwemishini kanye nesikhathi sokungasebenzi okubangelwa izinkinga zesisekelo.

Ukusebenza kahle kakhulu kokudambisa kunciphisa ukuphazamiseka kokudlidliza

Ukudlidliza kungenye yezinto ezibalulekile ezithinta ukunemba kokusikwa kwengilazi. Uma ukudlidliza okukhiqizwa ngesikhathi sokusebenza kwemishini kungenakuncishiswa ngesikhathi, kuzokwenza ithuluzi lokusika noma umsebe we-laser linyakaze, okuholela ezinkingeni ezifana nezindawo zokusika eziqinile kanye nemigqa yokusika engalingani. I-Granite inamandla amahle kakhulu okudambisa. Isakhiwo sayo samaminerali esiyinkimbinkimbi kanye nama-pores amancane ngaphakathi afana nezimbobo zemvelo zokudlidliza. Lapho ukudlidliza kudluliselwa esisekelweni se-granite, lezi zakhiwo nama-pores zingaguqula ngokushesha amandla okudlidliza abe amandla okushisa futhi ziwachithe, zinciphise kakhulu ukuphazamiseka kokudlidliza enkambisweni yokusika. Isibonelo, emishinini yokusika ingilazi ye-laser esheshayo, isisekelo se-granite singacindezela ngempumelelo ukudlidliza kwekhanda le-laser, siqinisekise ukuthi umsebe we-laser usebenza kahle ebusweni bengilazi futhi sifinyelele imiphumela yokusika enembile nekhwalithi ephezulu.

Ukumelana kahle nokuguguleka kwandisa impilo yesevisi yemishini

Ngesikhathi sokusebenza kwesikhathi eside kwemishini yokusika ingilazi, isisekelo sizodala ukungqubuzana okuthile nezingxenye zokusika, izinto zengilazi, njll. I-Granite inokumelana okuhle nokuguguleka ngenxa yobunzima bayo obukhulu kanye nesakhiwo sayo esiminyene. Thatha indawo yokusebenza yebhentshi lokusika njengesibonelo. Yenziwe nge-granite futhi ingamelana nokungqubuzana okubangelwa ukubekwa njalo kwengilazi kanye nokunyakaza kwezingxenye zokusika, futhi cishe ayinazo izinkinga ezifana nokuguguleka nokuklwebheka. Lokhu akugcini nje ngokuqinisekisa ukuthi indawo eyisisekelo ithambile futhi kugcina ukunemba okuphezulu kwemishini, kodwa futhi kwandisa kakhulu impilo yesevisi yesisekelo ngisho nayo yonke imishini yokusika ingilazi, kunciphisa izindleko zokuvuselela imishini yamabhizinisi.

Akuyona i-magnetic, kugwema ukuphazamiseka kwe-electromagnetic enqubweni yokusika

Kweminye imishini yokusika ingilazi ethuthukisiwe, izingxenye ze-elekthronikhi kanye nezinzwa zokunemba zisetshenziselwa ukulawula ukunemba kokusika kanye nendawo. Ukuzibutha okungenzeka kwesisekelo sensimbi kungabangela ukuphazamiseka kwe-electromagnetic kulawa madivayisi kagesi, okuthinta ukusebenza kwawo okuvamile kanye nokunemba kokudluliselwa kwesignali. Ngakolunye uhlangothi, i-granite iyinto engeyona eyensimbi engenawo amandla okuzibutha futhi ngeke ibangele ukuphazamiseka kwe-electromagnetic ezinhlelweni ze-elekthronikhi ngaphakathi kwemishini. Lokhu kwenza imishini yokusika ingilazi isebenze endaweni eqinile ye-electromagnetic, iqinisekisa ukudluliselwa okunembile kwezimpawu zokulawula ezahlukahlukene ngesikhathi senqubo yokusika, futhi ithuthukise ukunemba kokusika kanye nokuthembeka kokusebenza kwemishini.

Ekuphetheni, izisekelo ze-granite, ngokuqina kwazo okuvelele, ukuqina okuqinile, ukusebenza kahle kokudambisa, ukumelana nokuguguleka okuhle kanye nokungasebenzisi amandla kamagnethi, sezibe yisinqumo esifanele semishini yokusika ingilazi, okunikeza isiqinisekiso esiqinile semboni yokucubungula ingilazi ukuze ifinyelele ekukhiqizweni okunembile nokusebenza kahle kakhulu.

Isikhathi sokuthunyelwe: Meyi-19-2025