Ukuze kuqoshwe ngokunemba, ukukhetha isisekelo se-CNC kubalulekile ukuze kube nemiphumela emihle kakhulu. Izisekelo ze-CNC ze-Granite zingenye yezinketho ezithandwa kakhulu phakathi kochwepheshe. Kodwa kungani kufanele ucabangele lokhu okubalulekile ngezidingo zakho zokuqoshwa? Nazi izizathu ezimbalwa ezizwakalayo.

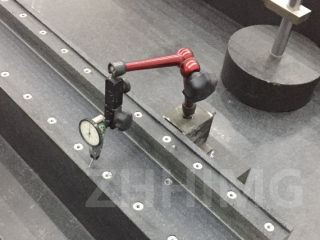

Okokuqala, i-granite yaziwa ngokuqina kwayo okumangalisayo. Ngokungafani nezinye izinto, i-granite ngeke igobe noma igobe ngokuhamba kwesikhathi, okuqinisekisa ukuthi umshini wakho we-CNC ugcina ukunemba kwawo. Lokhu kuzinza kubalulekile ekuqopheni, njengoba ngisho nokuphambuka okuncane kakhulu kungabangela ukungapheleli emkhiqizweni wokugcina. Isisekelo se-granite sinikeza isisekelo esiqinile esinciphisa ukudlidliza, okuholela ekuqopheni okuhlanzekile nokunembe kakhudlwana.

Enye inzuzo ebalulekile yezisekelo ze-CNC ze-granite ukuqina kwazo. I-Granite iyitshe lemvelo elingamelana nokusetshenziswa kakhulu futhi limelane nokuguguleka. Lokhu kuphila isikhathi eside kusho ukuthi akudingeki ukhathazeke ngokushintsha noma ukulungisa njalo, okwenza kube inketho engabizi ngokuhamba kwesikhathi. Ngaphezu kwalokho, i-granite imelana nokushintshashintsha kwezinga lokushisa, okusiza ukugcina ikhwalithi yokuqopha ihambisana.

I-Granite futhi inokushisa okuhle kakhulu, okusiza ekuqedeni ukushisa okukhiqizwa ngesikhathi senqubo yokuqopha. Lesi sici sibaluleke kakhulu ekusebenzeni okusheshayo njengoba sivimbela ukushisa ngokweqile kanye nomonakalo ongaba khona emshinini nasezintweni zokuqopha.

Ngaphezu kwalokho, ubuhle besisekelo se-granite CNC abunakuzinakwa. Ubuhle bayo bemvelo bunezela ukuthinta kobungcweti endaweni yakho yokusebenza, okwenza kube kuhle kakhulu kumabhizinisi agxile ekusebenzeni nasekubukekeni.

Sekukonke, ukukhetha isisekelo se-granite CNC sezidingo zakho zokuqopha kuyisinqumo esingathuthukisa kakhulu ikhwalithi kanye nokusebenza kahle komsebenzi wakho. Ukuqina kwe-granite, ukuqina kwayo, izakhiwo zokushisa, kanye nobuhle bayo kwenza kube ukukhetha okuhle kunoma yimuphi uchwepheshe wokuqopha.

Isikhathi sokuthunyelwe: Disemba-20-2024