Uma kukhulunywa ngokukhetha isisekelo semikhiqizo yokucubungula nge-laser, izinto ezenziwe ngazo isisekelo zingathinta kakhulu ukusebenza kanye nekhwalithi yokucubungula. Kunezinto ezahlukene ongakhetha kuzo, kodwa i-granite ibonakale iyisinqumo esihle kakhulu sesisekelo ngenxa yezakhiwo zayo ezihlukile kanye nezinzuzo zayo kunensimbi.

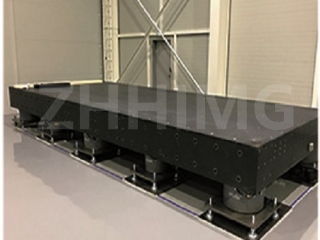

Esinye sezizathu eziyinhloko zokuthi kungani i-granite iyinto ekhethwayo yokusekela imikhiqizo yokucubungula i-laser ukuzinza kwayo okumangalisayo. I-granite yaziwa ngekhono layo lokugcina isimo sayo esizinzile, ngisho nangaphansi kwezimo ezimbi kakhulu, okubalulekile emishinini yokucubungula i-laser edinga ukunyakaza okuqondile njalo. Ukuzinza kwe-granite kusiza ekunciphiseni ukudlidliza, okungathinta ukunemba kanye nekhwalithi yokucubungula i-laser.

I-Granite nayo iyinto enhle kakhulu yokumunca ukudlidliza nokunciphisa ukudluliswa komsindo. Njengoba imishini yokucubungula i-laser isebenza, ikhiqiza ukudlidliza nomsindo ongathinta eminye imishini endaweni ezungezile. Ukusetshenziswa kwezisekelo ze-granite kunciphisa kakhulu lezi zinkinga, kudala indawo yokusebenza ezinzile nenokuthula.

Enye impahla ebalulekile ye-granite eyenza kube ukukhetha okuhle kwezisekelo zokucubungula nge-laser ukumelana kwayo nokushintsha kokushisa. Imishini yokucubungula nge-laser ikhiqiza ukushisa okuningi ngesikhathi sokusetshenziswa, kodwa ngenxa yokuthi i-granite iyisivikelo, iyasiza ekuqedeni ukushisa ngempumelelo, igcine imishini ipholile futhi igcina amazinga okusebenza ahambisanayo.

Ngokuphathelene nokugcinwa, i-granite nayo iyinto engadingi ukugcinwa isikhathi eside edinga umzamo omncane, ikakhulukazi uma iqhathaniswa nensimbi. I-granite imelana nokugqwala, ukugqwala, kanye nomonakalo wamakhemikhali, okusho ukuthi cishe ngeke ibole ngokuhamba kwesikhathi, futhi kunesidingo esincane sokugcinwa njalo, ukonga izindleko kanye nokunciphisa isikhathi sokungasebenzi.

Kubalulekile ukuqaphela ukuthi ukukhetha izinto eziyisisekelo zemikhiqizo yokucubungula i-laser kubalulekile ukuze kufezwe ukusebenza kahle kanye nokusebenza kahle okuphezulu. Nakuba insimbi iyindlela ethandwayo yezinto eziyisisekelo, izakhiwo ezihlukile ze-granite ziyenza ibe ukukhetha okuhle kakhulu okungathuthukisa ikhwalithi iyonke kanye nokunemba kokucubungula i-laser.

Ekuphetheni, ukukhetha i-granite njengesisekelo semikhiqizo yokucubungula i-laser kunikeza izinzuzo eziningana kunensimbi. Ukuqina okumangalisayo kwe-granite, ukugcinwa okuphansi, ukumelana nokushintsha kokushisa, kanye nekhono lokumunca ukudlidliza kwenza kube yinto efanelekile yezisekelo zokucubungula i-laser. Ukutshala imali ezisekelweni ze-granite kungathuthukisa ukusebenza kahle kanye nokunemba kwezinqubo ngenkathi kudala indawo yokusebenza ezinzile nefanele.

Isikhathi sokuthunyelwe: Novemba-10-2023