Uma kukhulunywa ngemikhiqizo yokuhlanganisa i-Precision Apparatus, ukukhetha izinto ezifanele kubalulekile. Phakathi kwezinto ezahlukahlukene ezitholakalayo, i-granite ithole ukuthandwa okukhulu eminyakeni edlule. Iyinto yemvelo esetshenziswa kabanzi kwezobunjiniyela kanye nokukhiqiza. Kulesi sihloko, sizoxoxa ngezizathu zokuthi kungani kufanele ukhethe i-granite esikhundleni sensimbi yemikhiqizo yokuhlanganisa i-Precision Apparatus.

1. Ukuqina okuphezulu nokuqina

I-Granite yaziwa ngokuqina kwayo okuphezulu nokuqina kwayo, okwenza ibe yinto enhle kakhulu yemikhiqizo yokuhlanganisa i-Precision Apparatus. Lokhu kungenxa yokuthi i-granite inesakhiwo esifanayo, okusho ukuthi inezakhiwo ezifanayo kuyo yonke into. Iphinde ibe ne-coefficient ephansi yokwanda kokushisa, okusho ukuthi ayishintshi ubukhulu bayo kakhulu ngaphansi kokushintsha kwezinga lokushisa. Lezi zakhiwo zenza i-granite ibe ukukhetha okuhle kwezicelo ezinembe kakhulu ezidinga ukuzinza okunobukhulu.

2. Ukunciphisa ukudlidliza

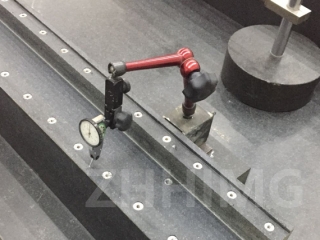

I-Granite inekhono elihle kakhulu lokunciphisa ukudlidliza, okuyinto ebalulekile emikhiqizweni yokuhlanganisa i-Precision Equipment. Ukudlidliza kungathinta kabi amathuluzi okunemba ngokungenisa ukunyakaza nomsindo ongafuneki, okungathinta ukunemba kwezilinganiso. Amakhono okunciphisa ukudlidliza kwe-Granite asiza ekunciphiseni ukudlidliza, okuqinisekisa ukuthi izilinganiso zinembile futhi zinembile.

3. Ayimelani nokugqwala

Ngokungafani nensimbi, i-granite imelana nokugqwala, okwenza kube ukukhetha okuhle kakhulu kwezicelo ezidinga ukumelana nezinto zamakhemikhali. Insimbi isengozini yokugqwala, okungenza buthaka ubuqotho bayo besakhiwo futhi kuphazamise ukunemba kokulinganisa. Ukumelana kwe-granite nokugqwala kusho ukuthi ihlala isikhathi eside futhi ihlala isikhathi eside, okwenza kube utshalomali oluhle kakhulu lwemikhiqizo yokuhlanganisa i-Precision Apparatus.

4. Kulula ukuhlanza nokunakekela

I-Granite kulula ukuyihlanza nokuyinakekela, okuyinto ebalulekile emikhiqizweni yokuhlanganisa i-Precision Equipment. Izinsimbi eziqondile zidinga indawo ehlanzekile nengenalo uthuli ukuqinisekisa ukunemba kwayo kanye nobude bayo. Ubuso obubushelelezi nobungenazo izimbobo be-Granite benza kube lula ukuyihlanza nokuyinakekela, okuqinisekisa ukuthi izinsimbi zihlala zihlanzekile futhi zingenazo izinto ezingcolisayo.

5. Kujabulisa ngendlela ekhangayo

Ngaphandle kwezakhiwo zayo zobuchwepheshe, i-granite nayo iyathandeka ngobuhle. Inobuhle bemvelo obunezela ekukhangeni okubonakalayo kwemikhiqizo yokuhlanganisa i-Precision Apparatus. I-granite iza ngemibala ehlukahlukene namaphethini, okwenza kube nokwenzeka ukudala imikhiqizo eyingqayizivele nekhangayo.

Ekuphetheni, i-granite iyisinqumo esihle kakhulu semikhiqizo yokuhlanganisa i-Precision Apparatus. Ukuqina kwayo, amandla ayo okunciphisa ukudlidliza, ukumelana nokugqwala, ukulungiswa okulula, kanye nokukhanga kobuhle kuyenza ibe yinto efanelekile yokusetshenziswa okunembe kakhulu. Ngakho-ke, uma ufuna into engaletha ukunemba, ukuzinza, kanye nokuqina, khona-ke i-granite iyindlela engcono kakhulu.

Isikhathi sokuthunyelwe: Disemba 22-2023