Umjaho womhlaba wonke oya ekuqondeni okunembile kakhulu—kusukela ekukhiqizeni kwe-semiconductor okuthuthukisiwe kuya ekulinganisweni kwezindiza okusezingeni eliphezulu—udinga ukuphelela ezingeni eliyisisekelo. Konjiniyela abakhetha ipulatifomu yokucacisa i-granite, umbuzo awukhona ukuthi kufanele bahlole ukuthi indawo yokusebenza ithambile yini nokuthi iyafana yini, kodwa kunalokho ukuthi bangawuchaza kanjani futhi bawulinganise kanjani ngokuqinile lo mbono oyisisekelo. Kwa-ZHONGHUI Group (ZHHIMG®), siyazi ukuthi noma yiliphi iphutha endizeni yokubhekisela lihumusha ngqo libe amaphutha abizayo kumkhiqizo wokugcina.

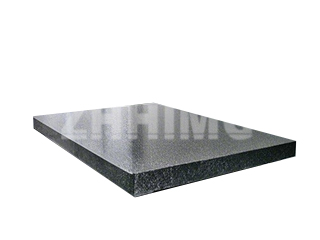

Ipulatifomu ye-granite, kalula nje, iyindilinga ye-zero-reference kuyo yonke inqubo yokulinganisa, ukuvumelanisa, kanye nokuhlanganisa elandelayo. Uma lesi sisekelo sisengozini, ubuqotho besistimu yakho yonke buyalahleka.

Ngale Kwesicaba: Ukuqonda Ukufana Nokufunda Okuphindaphindayo

Nakuba umqondo “wokuba yisicaba”—ibanga eliphakathi kwezindiza ezimbili ezihambisanayo ezizungeze yonke indawo—uqondile, ukunemba kwangempela kuncike emcabangweni wokufana. Indawo ingahlangabezana nokubekezelela ukuba yisicaba kodwa isaqukethe “amagquma nezigodi” zendawo. Yingakho onjiniyela kumele bahlole Ukunemba Kokufunda Okuphindaphindayo.

Ukufunda okuphindaphindiwe kungukuhlukahluka okuphezulu okubonwayo lapho igeyiji yokuqhathanisa ihanjiswa phezu kobuso, kuhlolwa iphuzu elifanayo. Lokhu kulinganisa okubucayi kuqinisekisa ukuzinza kobukhulu bendawo kanye nokuvumelana kuyo yonke ipulatifomu. Ngaphandle kokulawulwa okuqinile kwalesi silinganiso, ama-motor aqondile asheshayo angase abe namaphutha okubeka, futhi izigaba zokuthwala umoya zingaba nengcindezi yefilimu engalingani, okuholela ekushayweni okubi noma ekushukumeni kokunyakaza.

Yilapho isayensi yezinto ezibonakalayo ze-ZHHIMG® Black Granite izihlukanisa khona ngempela. Ubuningi bayo obuphezulu ≈3100 kg/m³) kanye nokuqina kwayo ngokwemvelo, kuhlanganiswe nezinqubo zethu zokulungisa nezokuqeda ezizimele, kunciphisa ngenkuthalo lokhu kuphambuka kwendawo. Asigcini nje ngokufeza ukuthamba; siqinisekisa ukuthi indawo ibushelelezi ngokulinganayo kuya emazingeni e-nanometer.

Indinganiso Yomhlaba Wonke Yekhwalithi Engangabazeki

Noma iyiphi ipulatifomu yokunemba kumele iqinisekiswe ngokuhambisana nohlelo lokulinganisa lomhlaba wonke. Siqinisekisa ukuthi izingxenye zethu azigcini nje ngokuhlangabezana kodwa futhi zidlula izidingo eziqinile ezibekwe yizindinganiso ezifana ne-ASME B89.3.7 eNyakatho Melika kanye ne-DIN 876 eYurophu, ikakhulukazi iBanga 00 elidingakalayo.

Ukufinyelela leli zinga lokunemba okuqinisekisiwe akunakwenzeka ngaphandle kokulawulwa kwekhwalithi yangaphakathi okuqinile. Inqubo yethu yokuqinisekisa iyisimangaliso sobunjiniyela ngokwayo. Yonke ipulatifomu ye-ZHHIMG® ihlolwa elabhorethri yethu ye-metrology ehlukanisiwe nokudlidliza, elawulwa amazinga okushisa—isikhungo esakhiwe ngemisele yokulwa nokudlidliza kanye nezitezi ezinkulu zekhonkrithi ukuqinisekisa indawo yokuqina okuphelele.

Ukulinganisa kwenziwa kusetshenziswa imishini eqinisekisiwe, elandelekayo njenge-Renishaw Laser Interferometers kanye namazinga kagesi e-WYLER. Asithembeli kumathuluzi okuhlola ayisisekelo; sisebenzisa izinga elifanayo lobuchwepheshe elisetshenziswa yizikhungo zezwe lonke ze-metrology ukuqinisekisa ukulandeleka okungenakuphikiswa kumadokhumenti ethu.

Ukugoqa Ngesandla: Ingxenye Yomuntu Ekuqondeni Okunembile Kwe-Nanometer

Mhlawumbe isici esiyingqayizivele kakhulu ekhonweni le-ZHHIMG® lokuletha ukufana okungenakuqhathaniswa ukuthembela kwethu ekuthinteni komuntu. Nakuba imishini ye-CNC ethuthukisiwe igubha ubuso, isigaba sokugcina nesibaluleke kakhulu senziwa yithimba lethu labachwepheshe abangochwepheshe, abaningi babo abanolwazi olukhethekile lweminyaka engaphezu kwamashumi amathathu ekubambeni izandla.

Laba basebenzi bezandla, njengoba amakhasimende ethu ebabiza kanjalo, “bahamba ngamazinga kagesi.” Basebenzisa amashumi eminyaka olwazi lwabo lokuthinta abalutholile ukuze balungise ubuso bube nokunemba okungenakulinganiswa nezinhlelo ezenzakalelayo, okwenza kube lula ukuphambuka okuncane ukuze kufezwe lokho kuthamba okufunwayo kwe-sub-micron. Lokhu kuhlanganiswa kobuchwepheshe obuthuthukisiwe kanye nekhono elingafani nelezandla kuyimfihlo ngemuva komehluko we-ZHHIMG®.

Uma ukhetha ipulatifomu yokucacisa i-granite, ukhetha i-reference plane yakho ephelele. Ngezinhlelo zokusebenza kuzo zonke i-semiconductor lithography, i-metrology yesivinini esikhulu, kanye ne-ultra-precision CNC machining, ukukhetha i-ZHHIMG® kuqinisekisa ukuthi wakhela phezu kwesisekelo sokuqina okuqinisekisiwe nokuhlala isikhathi eside.

Isikhathi sokuthunyelwe: Okthoba-17-2025