Emkhakheni wokukhiqiza ama-semiconductor, ukuhlanzeka kwendawo yokuhlanza kuthinta ngqo izinga lokukhiqiza ama-wafer kanye nokusebenza kwama-chips. Izitshalo zokukhiqiza ama-wafer eziphezulu ezi-5 emhlabeni wonke zisuse ngokuphelele izinto zensimbi ezivamile futhi zashintshela kumapulatifomu e-granite. Ngemuva kwalolu shintsho kukhona ukuphishekela okuphelele kwendawo engenakungcola emakamelweni okuhlanza. Amapulatifomu e-granite, anezimpawu zawo, abonise izinzuzo ezingenakuqhathaniswa emakamelweni ahlanzekile futhi abe yintandokazi entsha yezitshalo zokukhiqiza ama-wafer.

"Iphutha elibulalayo" lezinto zensimbi ephonswe emakamelweni ahlanzekile

Insimbi ephothiwe, njengezinto zendabuko zezimboni, yake yaba nezinzuzo ezithile ezimpahleni zemishini, kodwa inezinkinga eziningi endaweni yokuhlanza ye-semiconductor. Okokuqala, isakhiwo se-microsurface yensimbi ephothiwe asiqinile, sinenqwaba yama-pores kanye nemifantu emincane engabonakali ngeso lenyama. Ngesikhathi sokusebenza kwansuku zonke kwamagumbi okuhlanza, la ma-pores athambekele kakhulu ekumunceni uthuli, amabala kawoyela kanye nokungcola okuhlukahlukene kwamakhemikhali, abe yizindawo zokucashela imithombo yokungcola. Uma ukungcola kuqongelela, ngesikhathi sokusebenza okuqondile kokukhiqiza ama-wafer, angase awe futhi anamathele ebusweni be-wafer, okubangela izinkinga ezinkulu zekhwalithi njengemifudlana emifushane kanye nemifudlana evulekile ku-chip.

Okwesibili, insimbi ephothiweyo inokuqina okuphansi kwamakhemikhali. Ngesikhathi senqubo yokukhiqiza i-wafer, kusetshenziswa ama-reagent amakhemikhali ahlukahlukene abhodlayo njenge-hydrofluoric acid kanye ne-sulfuric acid. Insimbi ephothiweyo ithambekele ekugugulekeni nasekugugulekeni ngaphansi kokuguguleka kwalezi zinto zamakhemikhali. Ukugqwala kanye nama-ion ensimbi akhiqizwa ukugqwala akugcini nje ngokungcolisa indawo yokuhlanza kodwa futhi kungabhekana nokusabela kwamakhemikhali nezinto ezisebusweni be-wafer, kulimaze izakhiwo zomzimba nezamakhemikhali zama-wafer futhi kunciphise kakhulu isivuno somkhiqizo.

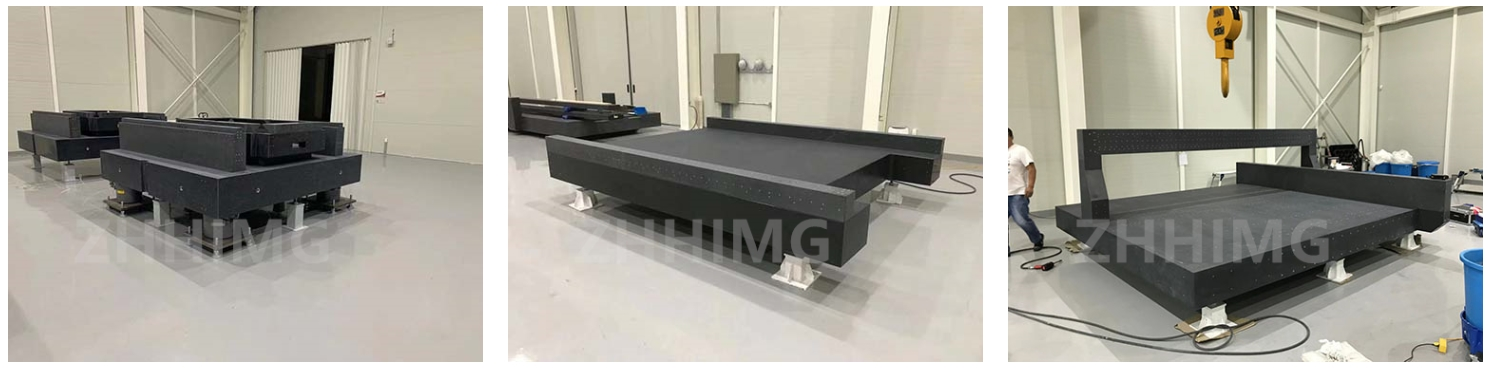

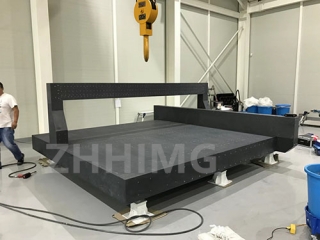

Isici "sokungangcoliswa kwe-zero" samapulatifomu e-granite

Isizathu sokuthi amapulatifomu e-granite athandwa yizitshalo zokukhiqiza i-wafer ze-TOP 5 emhlabeni sisesici sazo "sokungcola okungenawo ukungcola". I-Granite iyitshe lemvelo elakhiwe ngezinqubo ze-geological eminyakeni engamakhulu ezigidi. Amakristalu ayo amaminerali angaphakathi aqiniswa kakhulu, isakhiwo siminyene futhi sifana, futhi cishe azikho izimbobo ebusweni. Lesi sakhiwo esiyingqayizivele siqinisekisa ukuthi ngeke simunce uthuli nokungcola. Ngisho nasekuphazamisekeni komoya okuvamile kanye nemisebenzi yabasebenzi nemishini ekamelweni elihlanzekile, ubuso bepulatifomu ye-granite busengahlala buhlanzekile, buvimbele ukuzala nokusabalala kokungcola.

Ngokuphathelene nokuzinza kwamakhemikhali, i-granite isebenza kahle kakhulu. Izingxenye zayo eziyinhloko amaminerali afana ne-quartz ne-feldspar. Inezakhiwo zamakhemikhali ezizinzile kakhulu futhi ayisabelani kakhulu nanoma yiziphi izithasiselo zamakhemikhali ezivamile. Endaweni yamakhemikhali eyinkimbinkimbi yokukhiqizwa kwe-wafer, amapulatifomu e-granite angabhekana nokuguguleka kwama-reagent ahlukahlukene agqwalisayo kalula, ngaphandle kokukhiqiza imikhiqizo yokugqwala noma ukungcola kwe-ion yensimbi, okuhlinzeka ngeplatifomu eyisisekelo ephephile nehlanzekile yokukhiqizwa kwe-wafer. Okwamanje, i-granite ayihambisi ugesi futhi ayikhiqizi ugesi ongaguquki, ngaleyo ndlela igwema ingozi yokungcola okubangelwa ugesi ongaguquki obamba izinhlayiya zothuli futhi iqinisekise ikhwalithi yemvelo yegumbi elihlanzekile.

Ukukhethwa kwezinto ezibonakalayo ngokombono wezindleko kanye nenzuzo

Nakuba izindleko zokuqala zokuthenga amapulatifomu e-granite ziphakeme kakhulu kunezensimbi ephonswe ngensimbi, ngokuhamba kwesikhathi, izinzuzo eziphelele ezilethayo zidlula kakhulu umehluko wezindleko. Ukuhlanza nokugcinwa njalo kwamapulatifomu e-cast iron ngenxa yezinkinga zokungcola, kanye nokulahlekelwa okukhulu okubangelwa ukwanda kwamazinga okukhubazeka komkhiqizo, kugcine izindleko zokukhiqiza ziphezulu. Ipulatifomu ye-granite, enenzuzo yayo yokungabi nokungcola, inciphisa kakhulu imvamisa yokuhlanza nokugcinwa ekamelweni elihlanzekile kanye nezinga lokukhubazeka kwemikhiqizo, yehlisa izindleko zokusebenza, futhi ithuthukisa ukusebenza kahle kokukhiqiza kanye nekhwalithi yomkhiqizo. Thatha ifektri enekhono lokukhiqiza lonyaka lama-wafer ayisigidi esisodwa njengesibonelo. Ngemva kokusebenzisa amapulatifomu e-granite, inganciphisa ukulahlekelwa okubangelwa ukungcola ngama-yuan angaphezu kwezigidi eziyishumi minyaka yonke, futhi imbuyiselo yokutshalwa kwezimali inkulu kakhulu.

Izitshalo ezi-TOP 5 zomhlaba wonke zokwenza ama-wafer ziye zashiya insimbi ephothiweyo kanye namapulatifomu e-granite akhethiwe ngokusekelwe ekucabangeni okubanzi kwezidingo zezindawo zokuhlanza kanye nokusebenza kahle kokukhiqiza. Inzuzo yokungangcolisi nhlobo kwamapulatifomu e-granite inikeza isiqinisekiso esithembekile sokukhiqizwa kwama-wafer futhi iqhubekisela phambili ukukhiqizwa kwama-semiconductor ekuqondeni okuphezulu kanye namazinga aphezulu okukhiqiza. Ngokuthuthuka okuqhubekayo kobuchwepheshe be-semiconductor, amapulatifomu e-granite nakanjani azodlala indima ebaluleke kakhulu ekukhiqizweni kwama-wafer esikhathini esizayo.

Isikhathi sokuthunyelwe: Meyi-14-2025