Ukuphishekela ukunemba kuyisisekelo sokutholwa kwesayensi kanye nobunjiniyela obuthuthukisiwe. Emvelweni yesimanje yelabhorethri, ikakhulukazi leyo egxile ekuhlolweni okudingakalayo ngokomzimba njengokuhlolwa kwemishini, isayensi yezinto ezibonakalayo, kanye nokuhlaziywa kokudlidliza, isisekelo lapho lonke ucwaningo lusekelwe khona ngokuvamile siyisici esibaluleke kakhulu esinquma ubuqotho bedatha. Umbuzo olula, “Kungani i-Precision Granite Surface Plate iyisisombululo esisetshenziswa kakhulu?” wembula ukuhlangana okujulile kwesayensi yezinto ezibonakalayo, i-metrology, kanye nobunjiniyela obusebenzayo.

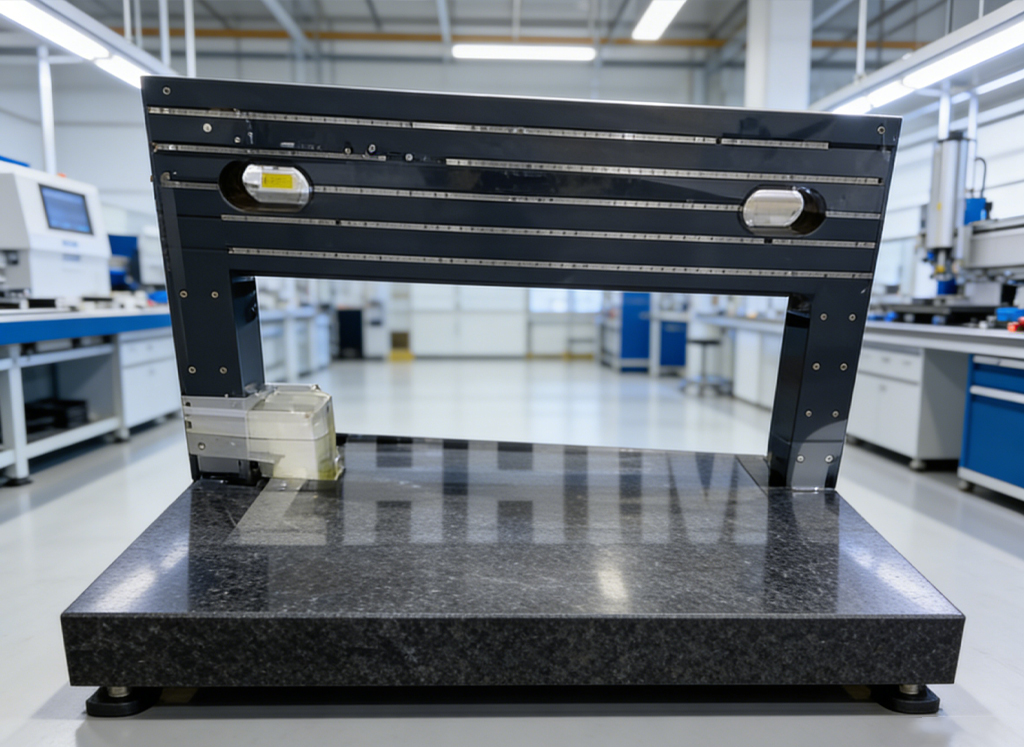

Lokhu akuyona nje ingxenye yetshe elicwebezelisiwe; kuyisisekelo esakhiwe ngokucophelela, isilinganiso sokuba yisicaba, kanye nengxenye yemishini engenzi lutho evumela ngokuyisisekelo i-metrology enembile kakhulu kanye nokuhlolwa kwesayensi okuthembekile.

Inkinga Yesisekelo Esingaphelele: Kungani Izitezi Zekhonkrithi Namatafula Ensimbi Ehluleka

Ngaphambi kokuhlola izimfanelo ze-granite, kubalulekile ukuqonda izinselele ezikhona ekusebenziseni izindawo zelebhu ezivamile. Ibhentshi elijwayelekile lensimbi noma phansi kwekhonkrithi, kungakhathaliseki ukuthi libonakala liqinile kangakanani, libhekene nokulinganiselwa okukhulu lapho libhekene nokulinganisa okuncane, ukusetshenziswa kwamandla, noma ukuhlolwa okunamandla:

-

Ukudluliswa Kokudlidliza: Insimbi inomsindo omkhulu. Noma yimuphi umsindo wendawo, ukuhamba ngezinyawo, noma umsindo womshini udluliselwa kalula futhi ukhuliswe etafuleni lensimbi, okufaka umsindo kuma-transducer anamandla azwelayo noma ama-accelerometer ngesikhathi sokuhlolwa kokudlidliza. Izitezi zekhonkrithi, yize zikhulu, zisadlulisa umsindo wokuzamazama komhlaba kanye nowesakhiwo ophansi.

-

Ukungazinzi Kokushisa: Izinsimbi (njengensimbi noma i-aluminium) zine-coefficient ephezulu yokwanda kokushisa (CTE). Ngisho nokushintshashintsha kwezinga lokushisa okuncane elebhu kungabangela ukuthi isisekelo sigobe noma sande ngendlela elinganisekayo, okuphazamisa ngokushesha ubuqotho bokulungiswa okubucayi kumasethingi okuhlola oomatshini.

-

Iphutha Lejiyomethri (Ukuthamba): Ukufinyelela ukuthamba kwangempela endaweni enkulu yensimbi kuyabiza futhi kunzima ukukugcina ngenxa yokucindezeleka kwangaphakathi kanye nemikhawulo yokukhiqiza. Ezivivinyweni ezidinga ukulinganiswa okuphelele kwamadivayisi okulinganisa, ama-height gauge, noma amathuluzi okukhanya, lokhu kungalungi kwejiyomethri okungokwemvelo kuyiphutha elibulalayo.

-

Ukuphazamiseka Kwamagnetic Nogesi: Izinsimbi eziningi ezithuthukisiwe, ikakhulukazi lezo ezisebenzisa izinzwa zamanje ze-eddy noma ama-high-sensitivity force gauges, zisengozini yokuhlaselwa yizinkambu zamagnetic noma zikagesi, okwenza izinto ze-ferromagnetic ezifana namatafula ensimbi zingafaneleki.

Isixazululo seGranite: Isayensi Yezinto Ezibonakalayo Ihlangana Ne-Metrology

Ukwamukelwa kwe-ZHHIMG® Black Granite—eyaziwa kakhulu ngezakhiwo zayo ezibonakalayo eziphakeme nezinobukhulu—njengezinto eziyisisekelo ze-Precision Granite Surface Plates kubhekana ngqo futhi kuxazulule le mikhawulo, okwenza kube ithuluzi elibalulekile le-metrology lamalabhorethri angokwenyama.

1. I-Ultimate Reference Plane: Ukunemba Kwejiyometri Okungalingani

Umsebenzi oyinhloko we-Ipuleti Lomphezulu Wegranitekuzosebenza njenge-datum ephelele, indiza yokubhekisela yethiyori lapho zonke izilinganiso zisekelwe khona.

-

Ukuthamba Nokuqondile Okumangalisayo: Ngokusebenzisa uchwepheshe wokugoqa kanye nezandla ezinekhono zezingcweti ezingochwepheshe—njengalabo base-ZHHIMG Group abafinyelela ukuthamba kwezinga le-nanometer—amapulatifomu e-granite ahlangabezana nezindinganiso zomhlaba wonke eziqinile kakhulu (isb., i-DIN, i-ASME, i-JIS). Leli zinga lokunemba okuqinisekisiwe akunakwenzeka ukuliphinda njalo noma ngendlela engabizi kakhulu ngezinto ezihlukile.

-

Ukuzinza Okulinganayo: I-Granite iyinto e-isotropic, okusho ukuthi izakhiwo zayo ziyafana kuzo zonke izinhlangothi, futhi ayinazo izingcindezi zangaphakathi ezivamile ensimbini eyenziwe ngomshini. Lokhu kuzinza kuqinisekisa ukuthi ipuleti ligcina ukunemba kwalo kwejometri eminyakeni eminingi yokusetshenziswa, okunciphisa isidingo sokulungiswa kabusha okuqhubekayo nokubizayo.

2. Ukudambisa Ukudlidliza Nokuqina: Ukuqinisekisa Idatha Ehlanzekile

Ezivivinyweni ezifana nokuhlolwa kokudlidliza noma ukuhlaziywa kokukhathala kwezinto ezishintshashintshayo, ukususa umsindo wemishini ongafuneki kubaluleke kakhulu.

-

I-Superior Damping Coefficient: I-granite enobukhulu obuphezulu, ikakhulukazi i-3100 kg/m³ ZHHIMG® Black Granite, ikhombisa ukungqubuzana okuphezulu kwangaphakathi. Leli khwalithi liyivumela ukuthi imunce amandla omshini futhi isuse ukudlidliza ngokushesha nangokuphumelelayo kunensimbi noma insimbi ephonswe ngensimbi. Umphumela uba umhlabathi ohlanzekile, othule womshini, ovumela izinzwa kanye nama-gauge okuphoqa ukuthi abambe idatha yangempela yokuhlola ngaphandle kokuphazamiseka.

-

I-High Modulus of Elasticity (Ukuqina): Naphezu kwamandla ayo okuncibilikisa, i-granite inokuqina okuphezulu. Lokhu kuqina okuphezulu kunciphisa ukuphambuka ngaphansi kwemithwalo esindayo evame ukuhlotshaniswa nohlaka lokuhlola omakhenikha, imishini emikhulu yokukhanya, noma izinhlelo ze-CMM (Coordinate Measuring Machine). Ukuntuleka kokuphambuka ngaphansi komthwalo kubalulekile ekugcineni ukuhambisana okubalulekile phakathi kwemishini yokuhlola nezinto eziphenywayo.

3. Ukungabi Namandla Kokushisa Namakhemikhali: Indawo Ezinzile

Indawo yelabhorethri ayivamile ukulawulwa ngokuphelele, okwenza ukuphendula ngezinto ezibonakalayo kube yinto ebalulekile.

-

I-Coefficient Ephansi Yokwanda Kokushisa (i-CTE): I-CTE ephansi ye-Granite isho ukuthi ngisho nokushintshashintsha kwezinga lokushisa okuncane kukhiqiza izinguquko ezincane kakhulu, umehluko omkhulu kunensimbi engakhula noma inciphe kakhulu. Lokhu kuzinza kokushisa okungenamsebenzi kuyisihluthulelo sokubanjwa kwedatha okuthembekile ngezikhathi ezinde zokuhlola.

-

Ayina-Hygroscopic Futhi Ayiboli: I-Granite ayimunci umswakama futhi imelana ngokwemvelo nokugqwala okuvela kumakhemikhali ajwayelekile elabhorethri kanye nokugqwala. Lokhu kuyenza ifaneleke ukusetshenziswa ezindaweni ezahlukahlukene, kusukela kumalabhorethri asogwini anomswakama ophezulu kuya emakamelweni ahlanzekile, okuqinisekisa ukusebenza kahle kwesikhathi eside kanye nobuhle ngaphandle kwesidingo sezingubo zokuvikela.

-

Okungeyona I-Magnetic: Njengento engeyona i-ferromagnetic, i-granite ibalulekile ekusethweni okubandakanya izinzwa ze-magnetic, ama-linear motors, noma imishini ye-electron beam ebucayi, okususa ingozi yokuphazamiseka kwe-magnetic okungcolisa idatha.

I-ZHHIMG®: Ukubeka Izinga Lomhlaba Wonke Lokunemba

Uma ukhetha i-PrecisionIpuleti Lomphezulu Wegraniteelebhu yakho, umthombo wokukhiqiza ubaluleke njengezinto ngokwazo. I-ZHONGHUI Group (ZHHIMG®) iqinise isikhundla sayo njengomholi womhlaba wonke ngokuhlanganisa amandla okukhiqiza asezingeni lomhlaba kanye nobuchwepheshe bobuciko beminyaka eminingi.

Ukuzibophezela kwethu ekhwalithini ephezulu kuboniswa yilokhu:

-

Isitifiketi Sekhwalithi Esiphelele: I-ZHHIMG® yiyona kuphela inkampani embonini ephethe izitifiketi ze-ISO 9001, ISO 45001, ISO 14001, kanye ne-CE ngasikhathi sinye, enikeza isiqinisekiso esingaqinisekiswa sekhwalithi, umthwalo wemfanelo wezemvelo, kanye nempilo nokuphepha emsebenzini.

-

Izakhiwo Ezisezingeni Eliphezulu: Indawo yethu yokusebenzela yokushisa okuhlala njalo kanye nomswakama engamamitha ayi-10,000 iyisiqiniseko sesithembiso sethu sekhwalithi. Lesi sakhiwo, esihlonyiswe ngephansi lezinga lezempi kanye nezici ezithuthukisiwe zokulwa nokudlidliza, senzelwe ngqo ukuqinisekisa ukuthi yonke ipuleti elingaphezulu kanye nengxenye yegranite kushiya ifektri yethu iqinisekisiwe ngezinga eliphakeme kakhulu, ilungele ukusetshenziswa ngokushesha ezicelweni zemboni ezidinga kakhulu ukucophelela.

-

Ukubambisana Komhlaba Wonke: Ukubambisana kwethu okuqhubekayo nezikhungo ezidumile njengeNational University of Singapore, Stockholm University, kanye nezikhungo ezahlukene zamazwe ngamazwe ze-metrology (UK, France, US) kubonisa umzamo wethu oqhubekayo wokuthuthukisa amasu okulinganisa nokugcina igunya lobuchwepheshe eliphelele emkhakheni wokusebenza ngokunemba.

Ngale Kwepuleti Lomphezulu: Ikusasa Lezingxenye Eziqondile

Izimiso ezenza ipuleti elingaphezulu libe yinto ebalulekile zifinyelela ngqo kwi-Granite Components yethu ethuthukisiwe kanye ne-Granite Machine Structures. Kungakhathaliseki ukuthi i-Granite Gantry Base eqinile kakhulu yomshini we-semiconductor lithography noma i-Granite Air Bearing assembly ehlanganisiwe, lezi zinto zakha umongo womkhakha wokunemba okuphezulu. Ngokuhlinzeka ngesisekelo esiqinile nesinamandla, i-ZHHIMG® ivumela onjiniyela ukuthi badlule imingcele yokunemba okufinyelelekayo emishinini ye-CMM, izinhlelo zokucubungula i-laser, kanye namapulatifomu okuhlola asheshayo.

Isiphetho: Tshala Imali Ekuthembekeni Kwedatha Yakho

Kunoma yiliphi ilabhorethri elizinikele ekuhlolweni kwemishini, ekuhlolweni kokudlidliza, noma kunoma yiluphi uhlobo lokuhlolwa okubonakalayo okunezingqinamba ezinkulu, i-Precision Granite Surface Plate akuyona into yokunethezeka—kuwukutshalwa kwezimali okuphoqelekile ekuthembekeni kwedatha. Ihlinzeka kuphela ngendiza yokubhekisela ewusizo neqinisekisiwe engahlukanisa ukuhlolwa ngokuthula nomsindo wemvelo ngenkathi ngesikhathi esifanayo iqinisekisa ukuphelela kwejometri. Ukukhetha umhlinzeki oqinisekisiwe njenge-ZHHIMG® kusho ukukhetha ibhentshi elithembekile emhlabeni wonke, elisekelwa izinto ezisezingeni eliphezulu kanye nokuzibophezela okungapheli esimisweni esithi: “Ibhizinisi elinembile alikwazi ukuba nzima kakhulu.”

Isikhathi sokuthunyelwe: Disemba 16-2025