Ezweni lokuncintisana lokukhiqizwa kweMold—ikakhulukazi isikhunta somjovo, ama-stamping dies, kanye namaphethini okukhipha asetshenziswa ekukhiqizweni kwezimoto, amadivayisi ezokwelapha, kanye nama-electronics abathengi—umkhawulo wephutha usuphelile. Isikhunta esingenaphutha siyisiqinisekiso sezigidi zemikhiqizo yokugcina ephelele. Yonke inqubo yokwenza isikhunta, kusukela ekusetshenzisweni kokuqala kokulawula izinombolo zekhompyutha (CNC) kuya ekuhlanganisweni kokugcina, incike ekhonweni lokuqinisekisa ngokuphindaphindiwe nokubeka izingxenye ngokunemba kwezinga le-micron. Lesi sidingo esiyisisekelo sichaza ukuthi kungani i-Precision Granite Surface Plate ingeyona nje ithuluzi, kodwa iwulwazi olubalulekile, olungaguquki lwemboni.

Indima yesikhulumi se-granite kulo mkhakha idlulela ngale kokuhlola ubuso okulula; isebenza njengomlamuli wokugcina wokunemba kwejometri, ivumela onjiniyela bekhwalithi ukuthi baqinisekise ubuqotho obukhulu bezingxenye ezibalulekile zesikhunta, baqinisekise ukushintshana kanye nokuhlangana okungenaphutha phakathi kwezingxenyana zesikhunta.

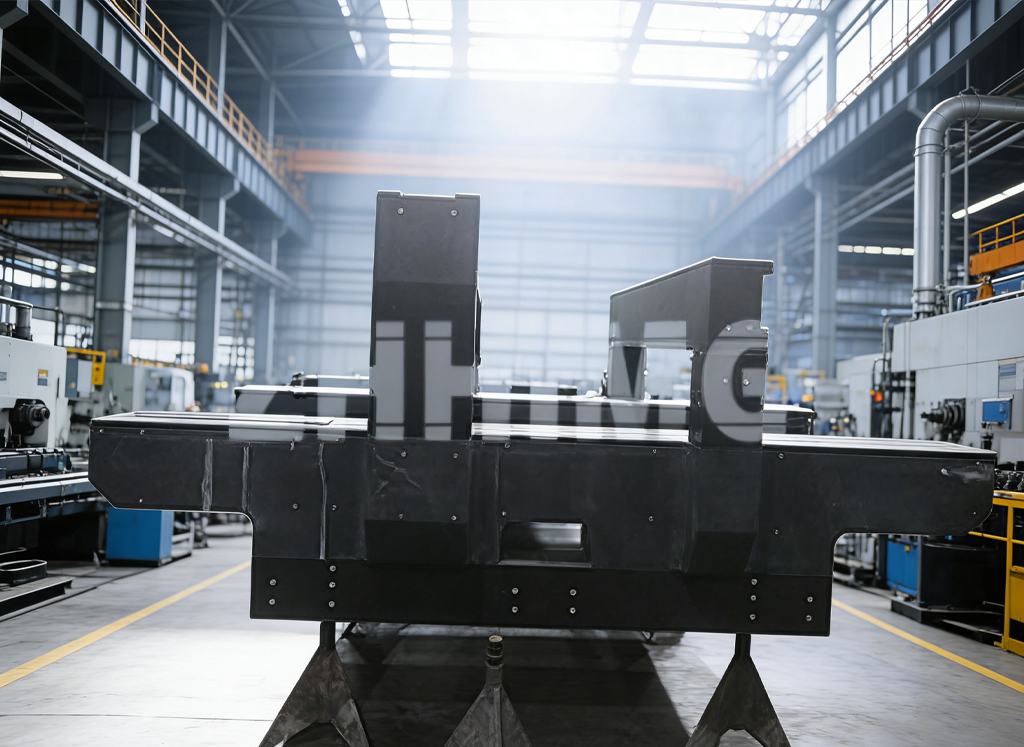

Inselele Yokukhiqiza Isikhunta: Ubuqotho Bejiyomethri Ngesivinini Esiphezulu

Izingxenye zesikhunta, njengemigodi, ama-core, nama-slide ayinkimbinkimbi, zivame ukuba nama-geometri e-3D ayinkimbinkimbi, ukubekezelelana okuqinile, kanye nezindawo ezicwebezelisiwe kakhulu. Noma yikuphi ukwehluleka kwesakhiwo sesikhunta—kungaba ukungalungi kahle, ukungalingani, noma ukujula okungalungile—kuzohumusha ngqo kube amaphutha kuzo zonke izingxenye ezilandelayo ezikhiqizwayo, okuholela ekulahlekelweni okukhulu komkhiqizo.

Izisekelo zokulinganisa zendabuko ezenziwe ngensimbi noma ngensimbi ephonswe zilwela ukugcina ukuzinza okudingekayo ngenxa yezici ezifana nokucindezeleka okusele, ukuphendula kokushisa, kanye nokunciphisa ukudlidliza okwanele. Abenzi besikhunta badinga ithuluzi lokukala elinikeza:

-

Ukuthamba Okuphelele: Indiza yokubhekisela eqinisekisiwe lapho kungahlolwa khona zonke izindawo eziphakeme, ukujula, nama-engeli.

-

Ukuzinza Okulinganayo: Izinto ezihlala zingathinteki ukushintshashintsha kwezinga lokushisa kwephansi le-workshop.

-

Ukuhlukaniswa Kokudlidliza: Isisekelo esiqinile esivimbela ukuphazamiseka kwemvelo ukuthi kungathinti izinsimbi zokulinganisa ezibucayi njengezikhombisi zokudayela, amazinga kagesi, noma ama-probe e-CMM.

Indima Ebalulekile KaGranite: Ukunemba Nokuhlanganiswa

UkunembaIpuleti Lomphezulu Wegraniteibhekana nalezi zinselele ngemisebenzi emibili eyinhloko esitolo sesikhunta: Ukuhlolwa Kokunemba Kwesikhunta kanye Nokubekwa Kwesisekelo Okubalulekile.

1. Ukuhlolwa Kokunemba Kwesikhunta: Idatha Yangempela Yekhwalithi

Uma kuhlolwa izingxenye ezahlukahlukene ezakha isethi yesikhunta, ipuleti le-granite linikeza indiza eqinisekisiwe, engaguquki yereferensi ye-zero:

-

Ukuqinisekiswa Kobukhulu: I-granite enobukhulu obuphezulu, njenge-ZHHIMG® Black Granite (enobukhulu obungaba ngu-3100 kg/m³), inikeza ukuqina okuphezulu, okuqinisekisa ukuthi ipuleti ayiphambuki ngaphansi kwesisindo sezisekelo zesikhunta ezinkulu noma ezisindayo. Lokhu kuvumela abasebenzi bokuqinisekisa ikhwalithi ukuthi baqinisekise ngokunembile ukufana, ubungako, kanye nokuba yisicaba besebenzisa ama-geuge okuphakama, amazinga kagesi, kanye nama-gauge blocks. Ukuncishiswa okuphezulu kwangaphakathi kwezinto kuqinisekisa ukuthi ukudlidliza kwemvelo akuphazamisi ukufundwa kokulinganisa okubucayi.

-

Ireferensi ye-Optical kanye ne-CMM: Ipuleti liyisisekelo esinqunyiwe sayo yonke imishini enembile kakhulu esetshenziswa ekutholakaleni kweMold Precision, kufaka phakathi i-Coordinate Measuring Machines (CMM Equipment), izinhlelo zokubona, kanye nama-jig okuhlola akhethekile. Ukuthamba kwesisekelo se-granite kunquma ngqo ukunemba okuphelele kwe-CMM, okwenza ukusetshenziswa kwamapuleti e-Grade 00 aqinisekisiwe noma amapuleti e-calibration-grade kungaxoxiswana ngawo emsebenzini we-mold obekezelela kakhulu.

-

I-Thermal Inertia Yokuthembeka: Njengoba izingxenye zesikhunta ngokwazo zipholile kusukela enkambisweni ye-CNC Machining, ziyancipha. I-Coefficient of Thermal Expansion (CTE) ephansi kakhulu ye-granite iqinisekisa ukuthi isisekelo sokubhekisela ngokwaso sihlala singaguquguquki ngokwesilinganiso, sinikeza ipulatifomu ezinzile yokulandelela nokulinganisa izinguquko zobukhulu ezihlobene nokupholisa zengxenye ngokunembile.

2. Ukubekwa Kwesisekelo Nokuhlanganiswa Kwezingxenye: Ukwakha Ukuphelela

Ikhwalithi yesikhunta ekugcineni inqunywa ukuthi izingxenye zaso eziyinkimbinkimbi—ama-cores, imigodi, ama-runners, kanye nama-ejector pins—zivumelana kahle kangakanani ngesikhathi sokuhlanganiswa. Ipuleti le-granite lenza lesi sinyathelo esibalulekile sibe lula:

-

Inkomba Yokuhambisana: Ezigabeni zokugcina zokuhlanganiswa kwesikhunta, izingxenye zivame ukufakwa okwesikhashana kwiGranite Platform ukuhlola ukuhambisana okuqondile nokwezinhlangothi ngaphambi kokubopha kokugcina. Izingxenye zeGranite ezikhethekile njengezikwele, ukufana, kanye namabhulokhi e-V, aqoqwe ngokunemba okufanayo kwe-sub-micron njengepuleti uqobo, asetshenziselwa ukubamba izingxenye eziyinkimbinkimbi ziqonde noma zihambisane nendiza ye-datum, okuqinisekisa ukuhlangana okungenaphutha kwezingxenyana ezimbili zesikhunta.

-

Ukuklwebha Nokufaka: Kuma-mold amadala noma akhethekile anembile adinga ukuklwebha noma ukufakela ngesandla ukuze kufinyelelwe ukuthintana okuhle, ipuleti le-granite linikeza indawo engcono kakhulu yokubhekisela yokudlulisa amabala aphezulu engxenyeni ye-mold kusetshenziswa i-bluing compound. Ukuthamba kanye nokuqina kwezinto kuqinisekisa ukuthi inqubo yokudlulisa ihlanzekile futhi inembe kakhulu.

-

Izisekelo Zokufaka Ngokwezifiso: Ngaphandle kwamapuleti ajwayelekile, Izakhiwo Nezisekelo Zomshini We-Granite Eziklanywe Ngokwezifiso zisetshenziswa njengezinkundla zokufaka ama-jig okuhlanganisa ngokunemba. Lawa ma-Granite Assemblies akhethekile ahlinzeka ngesakhiwo esizinzile ngokwezilinganiso esimelana nokugoba nokudlidliza, okwenza abahlanganisi bakwazi ukufeza ukubekezelelana okuqinile okudingekayo kwesikhunta esine-cavitation ephezulu kanye nezinga eliningi.

Umehluko we-ZHHIMG®: Umlingani Ekwenzeni Isikhunta Ngokucophelela

Embonini lapho isivinini nokunemba kubaluleke kakhulu, ukukhethaUmkhiqizi we-Precision GraniteUkuba negunya lomhlaba wonke kanye namandla angenakuqhathaniswa kubalulekile. I-ZHONGHUI Group (ZHHIMG®) iphakamisa izinga le-Granite Metrology Tools ngokusebenzisa:

-

Ubuhle Obuqinisekisiwe: Njengenkampani eyodwa kuphela embonini ephethe i-ISO 9001, ISO 45001, IS ngesikhathi esifanayo

14001, kanye nezitifiketi ze-CE, sibonisa ukuzibophezela okuhlelekile kwikhwalithi ehambisana nezindinganiso eziphakeme kakhulu ezifunwa yi-mold manufacturing supply chain.

14001, kanye nezitifiketi ze-CE, sibonisa ukuzibophezela okuhlelekile kwikhwalithi ehambisana nezindinganiso eziphakeme kakhulu ezifunwa yi-mold manufacturing supply chain. -

Isikali Sokukhiqiza Esingenakuqhathaniswa: Amandla ethu okucubungula izingxenye ezinkulu ze-granite—kufaka phakathi amayunithi angawodwa angafika kumathani ayi-100—kanye nemigqa yethu yokukhiqiza esheshayo iqinisekisa ukuthi singahlinzeka ngezisekelo ze-Granite ezinkulu, eziyinkimbinkimbi, nezinomthamo ophezulu ezidingwa yizimboni zezimoto kanye nezokubumba ze-elekthronikhi zomhlaba wonke ngaphandle kokuphazamiseka.

-

Ukuphishekela Ukuphelela: Kuqondiswa ukuzibophezela, “Akukho ukukopela, Akukho ukufihla, Akukho ukudukisa,” kanye nenqubomgomo yekhwalithi, “Ibhizinisi elinembile alikwazi ukuba nzima kakhulu,” yonke ipulatifomu iqedwa ku-10,000 m² Constant Temperature and Humidity Workshop yethu, okuqinisekisa ukunemba kwayo okuqinisekisiwe ngaphambi kokuba ifike esakhiweni sakho.

Ubunzima bokwenza isikhunta sesimanje budinga amathuluzi alula ngokwemvelo, azinzile, futhi athembeke ngokuphelele. I-Precision Granite Surface Plate iyithuluzi eliyisisekelo elihlinzeka ngeqiniso lejiyometri elidingekayo ukuguqula imiklamo yedijithali ibe ukuphelela ngokomzimba, okuqinisekisa ikhwalithi kanye nobude besikhathi sayo yonke isikhunta esikhiqizwayo.

Isikhathi sokuthunyelwe: Disemba 16-2025