Emikhakheni eqhutshwa ngokunemba kwemboni yanamuhla—kungaba yiziqhwaga zezindiza zaseNyakatho Melika noma onjiniyela bezimoto abasezingeni eliphezulu baseYurophu—kukhona iqiniso elingashiwongo elifundwa yiwo wonke umphathi wekhwalithi ekugcineni: isofthiwe yakho ifana kuphela nesisekelo somzimba sehadiwe yakho. Ngenkathi uhlangothi lwedijithali lwe-metrology luthola ukugqanyiswa okukhulu, impi yangempela yokunemba iyanqotshwa noma ilahleke kwisayensi yezinto ezibonakalayo yomshini ngokwawo. Lapho sibhekana nezingxenye ezidinga ukunemba kwe-sub-micron, isakhiwo somzimba seumshini wokulinganisa ohlanganisayoiba yinguquko ebaluleke kakhulu kulesi sibalo. Kusiholela embuzweni oyisisekelo wanoma yimuphi umenzi ofuna ukuthuthukisa indawo yakhe: endaweni ehlushwa ukudlidliza nokushintshashintsha kwezinga lokushisa, uqinisekisa kanjani ukuthi izilinganiso zakho zihlala ziphelele?

Ukuphishekela ukulinganisa okuphelele kuqala kusukela phansi, ngokoqobo. Kulabo ababhekene nezingxenye ezinkulu njengezinjini, izingxenye ze-fuselage, noma isikhunta esindayo sezimboni, umshini ojwayelekile wesitayela sebhuloho uvame ukufinyelela imikhawulo yawo engokwenyama. Yilapho umbhede we-Gantry Coordinate Measuring Machine ungena khona engxoxweni njengendinganiso yegolide yokuhlola ivolumu ephezulu, ukunemba okuphezulu. Ngokungafani nemishini emincane engase ihlushwe "ukukhala" okuhlobene ne-inertia noma ukuphambuka kwesakhiwo, uhlelo lwe-gantry lunikeza indawo yokusebenza enkulu, ezinzile. Kodwa umbhede womshini ungaphezu nje kwendawo yokubeka ingxenye; uyipulatifomu eklanywe ngokucophelela eyenzelwe ukuhlukanisa inqubo yokulinganisa ekuphazamisekeni kwephansi lefektri.

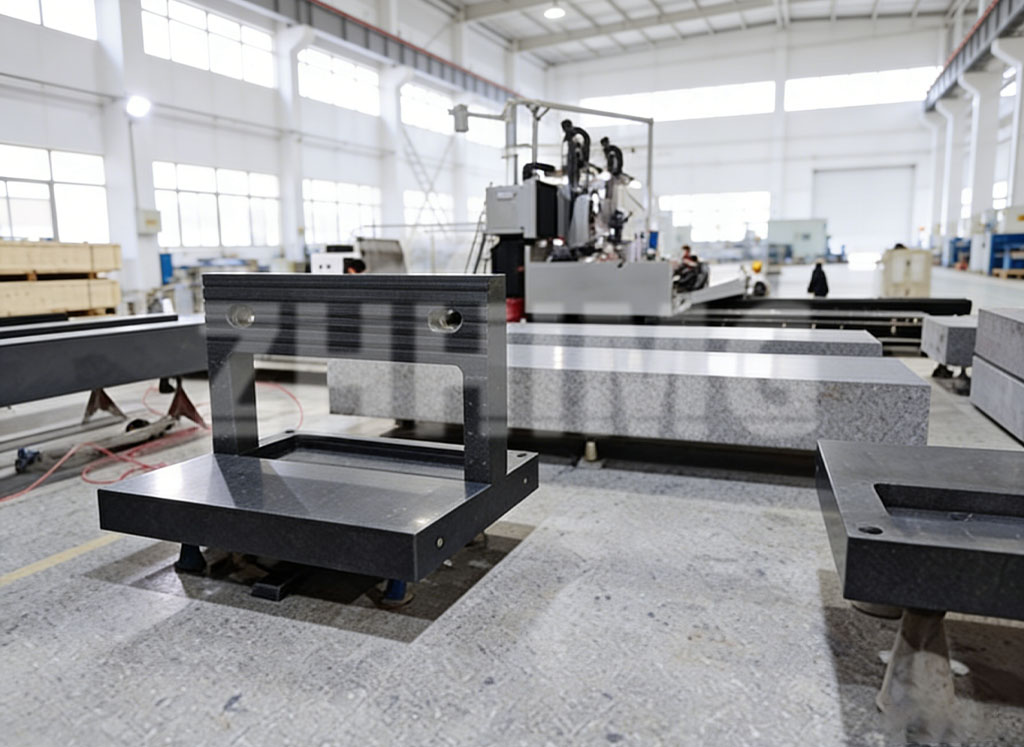

Okuphakamisa ngempela uhlelo lwezinga lomhlaba kusuka kolujwayelekile ukukhetha izinto zokwakha izindawo zalo eziqondisayo. Abakhiqizi abaningi baye bayeka ukusebenzisa izinsimbi zensimbi noma ze-aluminium zendabuko bakhethaisitimela se-granite. Isizathu silula: i-granite iyimpendulo yemvelo enkingeni yokungazinzi. Ixinene kakhulu, cishe ayithinteki emiphumeleni yokugqwala kwesikhathi, futhi ine-coefficient yokukhula kokushisa ephansi kakhulu kunezinsimbi eziningi. Uma wenza umjikelezo wokulinganisa oyinkimbinkimbi othatha amahora amaningi, awukwazi ukukhokhela "uhlaka" lomshini wakho ukuthi lukhule noma lunciphe ngoba umoya opholile wefektri ujikeleza noma ucime. Ngokusebenzisa isitimela se-granite, umshini ugcina indlela eqinile, eqondile esebenza njengereferensi engaguquki yawo wonke amaphuzu edatha athwetshuliwe.

Kodwa-ke, ngisho ne-granite enhle kakhulu ingaphansi kwemithetho yokungqubuzana uma ingaphathwanga kahle. Yilapho "umlingo" wobunjiniyela wangempela uvela khona ku-metrology ephezulu. Ukuze kufezwe ukunyakaza okulula nokulula okudingekayo ekuskeni ngesivinini esikhulu, abasunguli abaphambili bathuthukise ukusetshenziswa kwe-imigwaqo yokuntanta ye-graniteLezi zinhlelo zisebenzisa ifilimu encane yomoya ocindezelwe—ngokuvamile ubukhulu obuncane obungama-micron ambalwa—ukuphakamisa izingxenye ezihambayo zomshini wokulinganisa ohlanganisayo ebusweni be-granite. Lobu buchwepheshe obuthwala umoya buqinisekisa ukuthi akukho ukuxhumana kwemishini phakathi kwebhuloho elihambayo kanye nesitimela esimile. Ngenxa yokuthi akukho ukungqubuzana, akukho ukuguguleka, futhi okubaluleke kakhulu, akukho ukukhiqizwa kokushisa. Lokhu “kuntanta” kuvumela i-gantry ukuthi ishelele ngezinga lokuphindaphindeka okungenakwenzeka ngokomzimba ngama-roller omshini noma ama-ball bearings.

Ezinkampanini eziziqhenya ngokuba phakathi kwabahlinzeki abaphezulu emhlabeni jikelele, ukuhlanganiswa kwalezi zici akuyona into yokunethezeka ongayikhetha; kuyisidingo sobuchwepheshe. Lapho unjiniyela elabhorethri yobuchwepheshe obuphezulu ebheka imininingwane yombhede womshini wokulinganisa we-Gantry Coordinate, ufuna uhlelo olungamelana novivinyo lwesikhathi. Kudingeka bazi ukuthi isilinganiso esithathwe namuhla sizofana neso esithathwe eminyakeni emihlanu kusukela manje. Ngokuhlanganisa izakhiwo zemvelo zomswakama zesisekelo esikhulu se-granite kanye nokuhamba okungenazingxabano kwemigwaqo yokuntanta ye-granite, sakha indawo yokulinganisa ehlukanisiwe ngempumelelo nomhlaba wangaphandle.

Ngale kwehadiwe ebonakalayo, kunesici sengqondo kuleli zinga lokunemba. Lapho iklayenti livakashela indawo futhi libona ingxenye ihlolwa ohlelweni olukhulu lwe-gantry olusekelwe ku-granite, lidlulisela umlayezo wegunya kanye nekhwalithi engaguquki. Litshela ikhasimende ukuthi lo mkhiqizi akagcini nje "ehlola" ingxenye; kodwa uyayiqinisekisa ngokumelene nezindinganiso eziphakeme kakhulu zefiziksi nobunjiniyela. Endaweni yokuncintisana yokuhweba kwamazwe ngamazwe, lapho ukwethembana kuyimali ebaluleke kakhulu, ukuba nengqalasizinda efanele ye-metrology kuyisitatimende esinamandla senhloso.

Njengoba siqhubekela phambili enkathini ye-Industry 4.0, indima ye-umshini wokulinganisa ohlanganisayokuzoqhubeka nokukhula. Sibona ukuhlanganiswa okwengeziwe kwedatha yesikhathi sangempela, lapho umshini ungagcini nje ngokurekhoda ukwehluleka, kodwa ubikezela ukuthambekela. Kodwa kungakhathaliseki ukuthi i-AI noma isofthiwe ithuthuke kangakanani, izohlala incike ekuqineni komzimba komshini. Isitimela se-granite kanye nezinhlelo zokuntanta ziyiziqhawe ezithule zalolu shintsho lwezobuchwepheshe. Zinikeza "iqiniso" lokuthi izinhlelo zedijithali zidinga ukusebenza.

Ekugcineni, ukukhetha umlingani we-metrology kuncike ekuqondeni kwabo lezi zimiso eziyisisekelo. Kungaphezu nje kokuthengisa umshini; kumayelana nokuhlinzeka ngesisombululo sesikhathi eside sokunemba. Kungakhathaliseki ukuthi ulinganisa ithuluzi lezokwelapha elibucayi noma ingxenye enkulu yezindiza, umgomo uhlala ufana: ukuqiniseka okuphelele. Ngokutshala imali ezintweni ezisezingeni eliphezulu kanye nobuchwepheshe obuphambili bokuntanta, abakhiqizi abagcini nje ngokuthenga umshini—baqinisekisa ikusasa lekhwalithi yabo yokukhiqiza.

Isikhathi sokuthunyelwe: Jan-12-2026