Imboni ye-semiconductor isebenza ngesilinganiso sokunemba esidlulela imingcele yobuhlakani bomuntu. Enhliziyweni yokulawulwa kwekhwalithi yale mboni—isinyathelo sokugcina nesibalulekile ngaphambi kokuba i-chip ibhekwe njengelungele imakethe—kukhona izinto ezibonakala zilula: i-granite. Ngokukhethekile, amapulatifomu e-granite anembile ayisisombululo esisetshenziswayo sokuhlolwa kwe-chip ye-semiconductor, iqiniso elingamangaza labo abangaphandle kwensimu. Kwa-ZHONGHUI Group (ZHHIMG®), siyaqonda lobu budlelwano ngokujulile. Ubuchwepheshe bethu ekwakheni izingxenye ze-granite ezinembile kakhulu namathuluzi okulinganisa kusenze saba umlingani obalulekile kwezinye zezinkampani ezihamba phambili ze-semiconductor kanye ne-metrology emhlabeni. Ukuthembela ku-granite kulolu hlelo lokusebenza olubucayi akuyona indaba yesiko kodwa ye-physics kanye nobunjiniyela obuhlanzekile. Kumayelana nokuhlangabezana nesethi yezidingo ezihlukile nezidingayo okungekho okunye okungakwanelisa ngempumelelo.

Isidingo Esingapheli Sokuzinza

Ukuhlolwa kwe-semiconductor chip akukhona nje ukuhlola amaphutha; kumayelana nokuqinisekisa ukuthi izici ezincane kakhulu, ezivame ukulinganiswa ngama-nanometer, zakheke kahle. Le nqubo ihilela imishini eyinkimbinkimbi, njengezinhlelo zokuhlola ze-optical (AOI) kanye nezikena ze-CT zezimboni, okumele zihlale zizinzile ngokuphelele ngesikhathi sokuskena. Noma yikuphi ukudlidliza, ukwanda kokushisa, noma ukukhukhuleka kwesakhiwo kungaletha amaphutha, okuholela kumaphutha angamanga noma, okubi nakakhulu, amaphutha angatholakali.

Yilapho i-granite ikhanya khona. Ngokungafani nensimbi, ekhula futhi inciphe kakhulu ngokushintsha kwezinga lokushisa, i-granite ine-coefficient ephansi kakhulu yokwanda kokushisa. I-ZHHIMG® Black Granite yethu inobuningi obungaba ngu-3100kg/m3, okunikeza ukuzinza kokushisa okumangalisayo. Lokhu kusho ukuthi ipulatifomu ye-granite izogcina isimo sayo kanye nokuba yisicaba ngisho nasezindaweni lapho izinga lokushisa elizungezile lishintsha khona kancane. E-workshop elawulwa yisimo sezulu njengesikhungo sethu esingu-10,000m2, lapho izinga lokushisa ligcinwa khona ngokunemba kwezempi, ukuzinza kwe-granite akunakuqhathaniswa.

Ngaphezu kwalokho, izakhiwo ezinhle kakhulu zokudambisa i-granite zibalulekile. Imunca futhi isuse ukudlidliza komshini ngokwemvelo, ivimbele ukuthi kudluliselwe emishinini yokuhlola ebucayi. Esikhungweni sokukhiqiza esimatasa esigcwele imishini, lokhu kunciphisa ukudlidliza kubalulekile ekugcineni ubuqotho bokulinganisa. Ama-workshop ethu aklanywe ngalokhu engqondweni, anezitezi zekhonkrithi ezijiyile kakhulu kanye nemisele yokulwa nokudlidliza ukudala indawo lapho izingcweti zethu zingafinyelela khona ukunemba kwezinga le-nanometer emsebenzini wazo.

Ukufuna Ukungaguquguquki Okuphelele

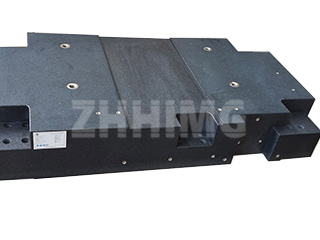

Ukuze uhlelo lokuhlola ama-chip lusebenze, isisekelo salo kumele sisondele kakhulu esicaba ngangokunokwenzeka. Umqondo "wobuso obusicaba" kulo mongo awubonakali kodwa wezibalo, ulinganiswa ngezinsimbi ezifana nama-interferometer e-laser e-Renishaw kanye namazinga kagesi e-Swiss Wyler. Umgomo womhloli wama-chip ukukala ubucaba be-chip kuma-micron ambalwa, noma ngisho nama-nanometer. Ukuze wenze lokhu, ipulatifomu ngokwayo kumele ibe yi-oda lobukhulu obucaba.

I-Granite iyinto, ngokusebenzisa amasu ethu akhethekile okubamba ngesandla, engagaywa ibe sezingeni lokuba yisicaba elingenakuqhathaniswa. Izingcweti zethu ezingochwepheshe, eziningi zazo ezineminyaka engaphezu kwengu-30 yesipiliyoni, zinomuzwa wokuthinta ovumela ukuthi "zizwe" ukuphambuka kokuba yisicaba kwama-micron ambalwa nje. Lokhu kuthinta komuntu, kuhlanganiswe nemishini yethu yezinga lomhlaba, kusenza sikwazi ukukhiqiza amapuleti omphezulu we-granite anokucaba kwezinga le-nanometer, okwenza kube yindawo efanelekile yokubhekisela ekulinganisweni nasekuhlolweni. Lesi yisisekelo lapho kwakhiwa khona ukuhlolwa kwe-semiconductor okunembile.

Ukubhekana Nezidingo Ezihlukile Zemboni Ye-Semiconductor

Imboni ye-semiconductor nayo inezidingo ezithile ngaphandle kokuqina nokuba yisicaba. Isibonelo, izinhlelo eziningi zokuhlola zisebenzisa ama-air bearings ukuze kuhambisane kahle. I-Granite iyindlela enhle kakhulu yokuqondisa imigwaqo yokuthwala umoya ngenxa yokuqina kwayo kanye nokuvuleka komoya okuvumela ukugeleza komoya okuhle nokulinganayo. Ama-air bearings ethu e-granite enziwe ngokwezifiso ukuqinisekisa ukunyakaza okubushelelezi nokunembile, okubalulekile ekuhlolweni okusheshayo nokunembile.

Ngaphezu kwalokho, i-ZHHIMG® Black Granite yethu ayisebenzi kumagnetic futhi ayihambisi ugesi, okuyinto ebalulekile ezingxenyeni ze-elekthronikhi ezizwelayo. Ayiphazamisi amasimu kagesi emishini yokuhlola noma i-chip ngokwayo. Lokhu kungathathi hlangothi kuyisici esinganikezwa amapulatifomu amaningi ensimbi.

Kwa-ZHHIMG®, asigcini nje ngokuthengisa i-granite. Sihlinzeka ngesisekelo esibalulekile sobuchwepheshe obuthuthuke kakhulu emhlabeni. Ukuzibophezela kwethu kumakhasimende ukuhlinzeka ngezixazululo ezingakhohlisi, ezingafihli, ezingadukisi. Sisebenzisana eduze nabalingani bethu, okuhlanganisa nezikhondlakhondla ezifana ne-Samsung kanye nezikhungo ze-metrology, ukuqinisekisa ukuthi imikhiqizo yethu ayihlangabezani nje kuphela nemininingwane yazo kodwa futhi inegalelo ekuthuthukisweni kobuchwepheshe bazo. Emdlalweni obalulekile wokukhiqiza ama-semiconductor, amapulatifomu e-granite aqondile e-ZHHIMG® angamandla athule, angashukumi, ahlinzeka ngokuqina nokunemba okuletha izinto ezintsha zakusasa ekuphileni.

Isikhathi sokuthunyelwe: Septhemba-28-2025