Inselele Engabonakali Ekulinganisweni Okunembile Kakhulu

Ezweni lokukhiqiza okuthuthukile, ukuhlolwa kwe-elekthronikhi, kanye nokulinganiswa kwezinzwa, impumelelo incike entweni eyodwa: ukuzinza kobukhulu. Noma kunjalo, ngisho nokusethwa okuqinile kakhulu kubhekene ne-disruptor ethule: ukuphazamiseka kwe-electromagnetic (EMI). Konjiniyela ababhekene nezinzwa ezibucayi, izingxenye zikamagnetic, noma ukuhlolwa kokuhambisana, izinto eziyisisekelo zepulatifomu yabo yokuhlola kungaba umehluko phakathi kwedatha ethembekile nemiphumela eyonakele.

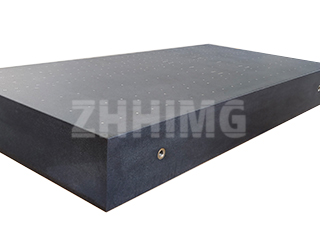

Kwa-ZHHIMG, siyaqonda lokhu kuxhumana okubalulekile. Izingxenye zethu ze-Precision Granite azikhethwanga nje ngenxa yokuba zithambile nokuqina kwazo; zikhethwa ngenxa yamandla azo ayisisekelo okumelana nokuphazamiseka kwamagnetic, okwenza zibe ukukhetha okuhle kakhulu kunezinto zendabuko ezifana nensimbi ephonswe noma insimbi.

Inzuzo Engeyona I-Magnetic ye-Natural Granite

Ukusebenza kahle kwe-granite njengeplatifomu yokulwa nogesi kuvela ekwakhekeni kwayo kwe-geological. I-Black Granite esezingeni eliphezulu iyidwala eliyi-igneous elakhiwe ngokuyinhloko ngamaminerali e-silicate, njenge-quartz ne-feldspar, angenawo amandla ogesi futhi angaqhubi ugesi. Lesi sakhiwo esiyingqayizivele sinikeza izinzuzo ezimbili eziqinisekile ezindaweni zokuhlola ezibucayi:

- Ukuqeda Ukuphazamiseka Kwe-Ferromagnetic: Ngokungafani nensimbi, engadonswa amandla yizinkambu zangaphandle futhi ilethe 'inkumbulo' noma ithonya elinamandla endaweni yokuhlola, i-granite ihlala ingasebenzi kahle. Ngeke ikhiqize, igcine, noma iphazamise insimu yamandla, iqinisekise ukuthi okuwukuphela kwesiginesha yamandla anamandla ekhona yilezo zezingxenye ezilinganiswayo.

- Ukumisa Ama-Eddy Currents: Insimbi iyi-conductor kagesi. Uma into eqhubayo ivezwa ensimini yamagnetic eshintshashintshayo (okuyinto evamile ekuhlolweni), ikhiqiza ama-electrical currents ajikelezayo aziwa ngokuthi ama-eddy currents. La ma-currents adala ama-ether magnetic field awo, engcolisa indawo yokulinganisa ngenkuthalo. Njenge-insulator kagesi, i-granite ayikwazi nje ukwakha la ma-currents aphazamisayo, ngaleyo ndlela isuse umthombo omkhulu womsindo nokungazinzi.

Ngale Kokuhlanzeka Kwamagnetic: I-Metrology Trifecta

Nakuba isici esingeyona i-magnetic sibalulekile, amapulatifomu e-granite metrology e-ZHHIMG anikeza uhlu oluphelele lwezimpawu eziqinisa ubumsulwa bokulinganisa:

- Ukudambisa Ukudlidliza Okuphakeme: Isakhiwo esiqinile, esinohlamvu oluncane se-granite yethu ngokwemvelo simunca ukudlidliza komshini nokuzwakalayo, sinciphise umsindo ongonakalisa ukufundwa kwezinzwa zikagesi ezizwela kakhulu.

- Ukuzinza Kokushisa: I-Granite ibonisa i-coefficient ephansi kakhulu yokwanda kokushisa. Lokhu kusho ukuthi ngokungafani nensimbi, engagoba noma ikhukhuleke ngenxa yezinguquko zokushisa (ngezinye izikhathi ezibangelwa ukushisa kwamanje kwe-eddy), i-reference plane ye-granite igcina i-geometry yayo, iqinisekisa ukuzinza kobukhulu kanye nokuphindaphindwa kwe-sub-micron.

- Ukuqina Okungagqwali: I-Granite imelana ngokwemvelo nokugqwala, ukugqwala, kanye namakhemikhali avamile, okuqinisekisa ubuqotho bepulatifomu isikhathi eside kanye nokunemba ngaphandle kokuwohloka okubonakala ezisekelweni zensimbi ephonswe.

Izindawo Ezifanele Ze-ZHHIMG Granite

Lezi zakhiwo zenza i-granite yokunemba ye-ZHHIMG ibe yiPlatform ebalulekile ye-Ultra-Precision yezimboni ezihamba phambili emhlabeni jikelele. Sakha isisekelo esiqinile sezinhlelo zokusebenza ezibalulekile, okuhlanganisa:

- Ukuhlolwa Kokuhambisana Kwe-Electromagnetic (EMC) kanye ne-EMI

- Ukulinganiswa Nokuhlolwa Kwezinzwa Ze-Magnetic

- Imishini Yokulinganisa Ehlanganisiwe (ama-CMM)

- Ukuhlolwa Nokwenziwa Kwe-Wafer Ye-Semiconductor

- Izinhlelo Zokuqondanisa Optical kanye Ne-Laser

Uma ukuhlola noma ukukhiqiza kwakho kudinga i-Vibration Damping Base enikeza ubumsulwa obunamandla kanye nokuqina okungantengantengi, thembela ulwazi lwe-ZHHIMG ku-Custom Granite Components ukuze lunikeze ikhambi eliphelele.

Isikhathi sokuthunyelwe: Okthoba-14-2025