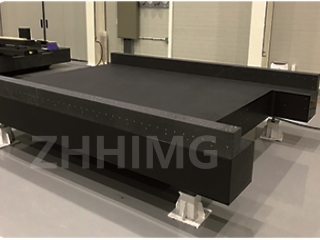

Ipulatifomu yokunyakaza yokuhlukanisa ukudlidliza okusebenzayo kwe-XYT isibe yithuluzi eliyinhloko lokufeza ukulawulwa kokunyakaza okunembe kakhulu ekukhiqizeni okunembe, ocwaningweni lwesayensi nasekuhloleni. Phakathi kwazo, ukusetshenziswa kwesisekelo se-granite kuletha izinzuzo eziningi ezibalulekile ekuthuthukiseni ukusebenza kwepulatifomu.

Ukuqina okuhle kakhulu, ukuhlukaniswa nokuphazamiseka kwangaphandle

Isisekelo segranite sincishisiwe yizigidi zeminyaka ye-geology, futhi amaminerali angaphakathi axhumene kakhulu futhi isakhiwo siminyene futhi sifana. Uma sibhekene nemithombo yokudlidliza yangaphandle eyinkimbinkimbi, njengokusebenza kwemishini emikhulu endaweni yokusebenzela yasefektri kanye nokudlidliza okunamandla okukhiqizwa yithrafikhi ezungezile, kufana nenqaba eqinile. Ngesakhiwo sekristalu esiyinkimbinkimbi, isisekelo segranite singavimba futhi sinciphise ukudlidliza ngempumelelo, okunganciphisa ubukhulu bokudlidliza obudluliselwa epulatifomu yokunyakaza yokuhlukaniswa kokudlidliza okusebenzayo kwe-XYT ngokunemba okungu-80%. Uma sithatha indawo yokukhiqiza ama-chip e-semiconductor njengesibonelo, inqubo ye-photolithography idinga ukuzinza okuphezulu kakhulu kwepulatifomu, futhi ngisho nokudlidliza okuncane kungaholela ekuphambukeni kwephethini yama-chip. Kulesi simo, ipulatifomu ye-XYT esekelwa yisisekelo segranite iqinisekisa ukusebenza okunembile kwemishini ye-lithography, inikeza isisekelo esiqinile sokukhiqiza ama-chip, futhi isiza ukuthuthukisa isivuno sama-chip.

Ukuqina okuhle kakhulu kokushisa kuqinisekisa ukunemba okuqhubekayo

Ukushintshashintsha kwezinga lokushisa kuyinkinga enkulu ethinta ukunemba kwemishini enembile, kodwa isisekelo se-granite sixazululwa kalula ngokusebenzisa i-coefficient ephansi kakhulu yokwanda kokushisa. I-coefficient yayo yokwanda kokushisa ngokuvamile ingu-5-7 × 10⁻⁶/℃, futhi usayizi awushintshi kakhulu lapho izinga lokushisa lishintsha. Emkhakheni wezinkanyezi, ipulatifomu yokunyakaza yokuzihlukanisa kwe-XYT enembile yokuzivumelanisa kahle ne-telescope lens ngesisekelo se-granite, noma ngabe umehluko wokushisa phakathi kwemini nobusuku ubalulekile, isengaqinisekisa ukuthi ukunemba kokubekwa kwelensi kugcinwa ezingeni le-submicron, kusize izazi zezinkanyezi ukuthi zibambe amandla angabonakali ezidalwa zasezulwini ezikude.

Ubulukhuni obuphezulu kanye nokumelana nokuguguleka ukuqinisekisa ukuqina kwesikhathi eside

Ipulatifomu yokunyakaza kokuzihlukanisa kokudlidliza okusebenzayo kwe-XYT inomqhudelwano othile nesisekelo ngesikhathi sokusebenza kwesikhathi eside. Ukuqina okuphezulu kwe-granite, ubulukhuni be-Mohs bufika ku-6-7, ukumelana okuhle kakhulu kokuguguleka. Elabhorethri yesayensi yezinto zokwakha, ipulatifomu ye-XYT esetshenziswa njalo, isisekelo sayo se-granite singamelana ngempumelelo nokulahlekelwa ukudlidliza kwesikhathi eside, uma kuqhathaniswa nesisekelo esivamile, singandisa umjikelezo wokugcinwa kwepulatifomu ngaphezu kuka-50%, sinciphise izindleko zokugcinwa kwemishini, futhi siqinisekise ukuqhubeka komsebenzi wocwaningo lwesayensi.

Ipulatifomu yokunyakaza yokuhlukanisa ukudlidliza okusebenzayo kwe-XYT enesisekelo se-granite, ukusebenza okuhle kakhulu maqondana nokuzinza, ukuzinza kokushisa kanye nokuqina, kuyenza ivelele phakathi kwemishini eminingi yokunemba.

Isikhathi sokuthunyelwe: Ephreli-11-2025