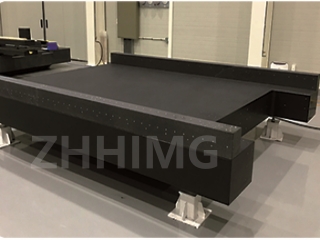

Ipulatifomu yokunyakaza kwe-gantry enembile ye-XYZT isebenzisa izingxenye ze-granite, ezinezidingo eziningi ezikhethekile enkambisweni yokufaka nokulungisa amaphutha. Uma kuqhathaniswa nenqubo yokufaka izingxenye zezinto ezivamile, kuyadingeka ukunikeza ukulawula okwengeziwe ezixhumanisini ezibalulekile ukuze kunikezwe ukusebenza okugcwele ezinzuzweni zayo zokusebenza okunembe kakhulu.

Ukusekelwa kwesisekelo kanye nokulungiswa kwezinga

Izingxenye zezinto ezivamile zinezidingo ezibanzi zokusekelwa kwesisekelo, kuyilapho izingxenye ze-granite zidinga ukwesekwa kwesisekelo okuqinile nokuyisicaba ngenxa yobuningi bazo obukhulu kanye nokuthungwa okubuthakathaka. Ngaphambi kokufaka, qiniseka ukuthi amandla okuthwala epulatifomu yokufaka noma yesisekelo okungenani aphindwe ka-2-3 kunesisindo sonke semishini, futhi uqinisekise ukuthi iphutha lokusicaba lesisekelo lilawulwa ngaphakathi kuka-±0.1mm/m ngokusebenzisa izinga elinembile kakhulu. Ngesikhathi senqubo yokufaka, insimbi yobungcweti ye-wedge kanye nama-bolt okulungisa asetshenziswa ukulungisa kahle izinga lepulatifomu, ukuze ukuphambuka okuvundlile kwepulatifomu ye-XYZT kungadluli ku-±0.05mm/m kunoma iyiphi indlela. Lesi sixhumanisi sibalulekile, ukuphambuka okuncane, izingxenye ze-granite ezisetshenziswa isikhathi eside zingase zibe ngenxa yokuqhekeka kwamandla okungalingani kwendawo, okuthinta ukunemba nokuzinza kwepulatifomu.

Ukuphatha nokubeka endaweni

Izingxenye zegranite zinzima futhi zibuthakathaka, futhi kufanele ziphathwe ngokucophelela okukhulu. Ngokungafani nezinto ezivamile kungaba ukuphakamisa okulula, izingxenye zegranite zokuphatha kumele zisebenzise imishini yokuphakamisa yobungcweti, efakwe amaphedi okuvikela athambile ukuvimbela ukungqubuzana. Enqubweni yokubeka, iphutha lokubeka ipulatifomu lilawulwa ngaphakathi kuka-±0.02mm ngokusebenzisa izinsimbi zokulinganisa ezinembile kakhulu njenge-laser rangefinder kanye nesiteshi esiphelele. Uma kuqhathaniswa nezidingo zokunemba kokubeka okukhululekile kokufakwa kwezingxenye zezinto ezivamile, ukubeka okunembile kwezingxenye zegranite kuhlobene ngqo nokunemba kokunyakaza okulandelayo, uma ukubeka kungalungile, kuzoholela ekucindezelekeni okungalingani kwesitimela sokuqondisa, isikulufu se-lead nezinye izingxenye zokudlulisela, kukhulise ukuguguleka, kunciphise impilo yesevisi yepulatifomu kanye nokunemba kokunyakaza.

Xhuma bese ulungisa

Izindlela zokuxhumanisa zezingxenye zezinto ezivamile ziyahlukahluka futhi izinga lokubekezelela amaphutha liphezulu, kuyilapho ukuxhumanisa izingxenye zegranite kudinga ukucatshangelwa okukhethekile. Uma usebenzisa i-binder ekhethekile noma uxhumano lwe-mechanical, kubalulekile ukusebenza ngokuhambisana nezidingo zenqubo. Lapho kusetshenziswa izinamathiseli, ukujiya kwengubo kanye nokufana kumele kulawulwe ngokunembile ukuqinisekisa amandla e-bond ngenkathi kugwenywa ukugxilisa ingqondo okubangelwa ukuqina kwe-binder okungaguquki. Ukuxhumeka kwe-mechanical kufanele kukhethe ama-bolts nama-nuts afanele, kulawule i-torque yokuqinisa, futhi kuvimbele ukuqina ngokweqile okuholela ekuqhekekeni kwe-granite. Ngemva kokuxhumeka sekuqediwe, i-ultrasonic flaw detector kanye neminye imishini isetshenziselwa ukuthola izingxenye zokuxhumanisa ukuqinisekisa ukuthi azikho iziphambeko, nokuqinisekisa ukuzinza kwesakhiwo sonke sepulatifomu kanye nekhono lokugcina ukunemba.

Ukuqaliswa kohlelo lukagesi nolokulawula

Esigabeni sokulungisa amaphutha kagesi nohlelo lokulawula, ukuzwela kwezingxenye zezinto ezivamile ekulungisweni kahle kwamapharamitha kagesi kuphansi kakhulu, futhi izici ezinembile kakhulu zezingxenye zegranite zidinga ukuhambisana okunembile kakhulu kwamapharamitha kagesi. Kuyadingeka ukusebenzisa isofthiwe yobuchwepheshe yokulungisa amaphutha ukuze kulinganiswe kahle isivinini semoto, i-torque kanye neminye imingcele, ukuze inqubo yokusheshisa kanye nokunciphisa ijubane lokunyakaza kwepulatifomu ibushelelezi futhi ibushelelezi, futhi indawo isheshe futhi inembile. Ukuqapha isimo sokunyakaza kwepulatifomu ngesikhathi sangempela ngezinzwa ezinembile kakhulu, impendulo ohlelweni lokulawula ukuze kwenziwe ngcono futhi kulungiswe, ukuqinisekisa ukuthi ipulatifomu ingenziwa ngokunembile ngaphansi kwemiyalelo yokunyakaza ezingeni le-micron noma ngisho ne-nanometer, okunikeza ukudlala okugcwele emandleni okunemba okuphezulu kwezingxenye zegranite.

Isikhathi sokuthunyelwe: Ephreli-14-2025