Ibhulogi

-

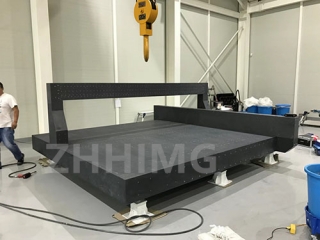

Ingabe kukhona imikhawulo ekusetshenzisweni kwezisekelo ze-granite zemishini yokunemba?

I-Granite iyindlela ethandwayo yezisekelo zemishini yokunemba ngenxa yokuqina kwayo okumangalisayo, ukuqina kanye nokumelana nokuguguleka. Kodwa-ke, uma kukhulunywa ngokusebenzisa izisekelo ze-granite zemishini yokunemba, kunezici ezithile kanye nemikhawulo okufanele icatshangelwe. Enye...Funda kabanzi -

Ingabe isisekelo se-granite singenziwa ngokwezifiso ukuze sivumelane nezidingo ezithile zemishini?

I-Granite iyindlela ethandwayo yokusetshenziswa kwe-substrate ezimbonini ezahlukahlukene ngenxa yokuqina kwayo, ukuzinza kanye nokumelana nokuguguleka. Ivame ukusetshenziswa njengesisekelo semishini esindayo, imishini enembile, kanye nezinsimbi zesayensi. Enye yezinzuzo eziyinhloko zokusebenzisa i-granite ...Funda kabanzi -

Yiziphi izici okufanele zicatshangelwe lapho ukhetha isisekelo se-granite semishini yokunemba?

Uma ukhetha isisekelo se-granite semishini yokunemba, izici eziningana kufanele zicatshangelwe ngokucophelela ukuqinisekisa ukusebenza kahle kanye nokunemba. I-granite iyindlela ethandwayo yezisekelo zemishini yokunemba ngenxa yokuqina kwayo okuhle kakhulu, ukwanda okuphansi kokushisa kanye nokuphakama okuphezulu ...Funda kabanzi -

Ukuze uthole izisekelo zemishini enembile, i-granite iqhathaniswa kanjani nezinye izinto, njengensimbi noma i-aluminium?

Ukunemba kweGranite: Isisekelo semishini yokunemba uma kuqhathaniswa nensimbi ne-aluminium. Ukuze uthole izisekelo zemishini yokunemba, ukukhethwa kwezinto kubalulekile ekuqinisekiseni ukunemba nokuzinza. I-Granite ibilokhu iyisinqumo esithandwayo sezisekelo zemishini yokunemba ngenxa...Funda kabanzi -

Ingabe zikhona izidingo ezithile zokugcinwa kwesisekelo se-granite?

I-Granite iyindlela ethandwayo yama-countertop, phansi, nezinye izindawo ngenxa yokuqina kwayo nobuhle bayo bemvelo. Kodwa-ke, ukuqinisekisa ukuthi isisekelo sakho se-granite sihlala sisesimweni esihle, kubalulekile ukulandela izidingo ezithile zokulungisa. Enye yezinto ezibalulekile zokulungisa...Funda kabanzi -

Ingabe isisekelo segranite singamelana nemithwalo esindayo ngaphandle kokuthinta ukunemba?

Ngenxa yokuqina kwayo nokuqina kwayo, i-granite iyindlela ethandwayo yokukhetha izisekelo zemishini nemishini esindayo. Yaziwa ngekhono layo lokubekezelela imithwalo esindayo ngaphandle kokubeka engcupheni ukunemba, okwenza ibe yinto efanelekile yokusetshenziswa edinga ukunemba nokuqina...Funda kabanzi -

Yiziphi izinhlobo ezivamile zemishini yokunemba ezuza ezisekelweni ze-granite?

Imishini yokunemba kwe-granite isetshenziswa kabanzi ezimbonini ezahlukahlukene ngenxa yokuzinza kwayo okuhle kakhulu, ukuqina kanye nokunemba. Imishini yokunemba evamile ezuza ezisekelweni ze-granite ifaka phakathi imishini yokulinganisa ehlanganisiwe (ama-CMM), ama-comparators optical, izigaba kanye nobuchwepheshe bokucacisa...Funda kabanzi -

Ukuqina kwe-granite kuthinta kanjani ukunemba kwezinsimbi zokunemba?

Amapulatifomu okunemba kwe-granite asetshenziswa kabanzi ezimbonini ezahlukahlukene ngenxa yokuqina kwawo okuhle kakhulu nokunemba. Ukuqina kwe-granite kudlala indima ebalulekile ekuqinisekiseni ukunemba kwezinsimbi zokunemba. I-granite yaziwa ngokuqina kwayo okuphezulu kanye nokwanda okuphansi kokushisa,...Funda kabanzi -

Yini eyenza i-granite ibe yinto efanelekile yokusekela imishini enembile?

Ipulatifomu yokucacisa i-granite: into efanelekile yesisekelo semishini yokucacisa Uma kukhulunywa ngezisekelo zemishini yokucacisa, i-granite ibilokhu ibhekwa njengento efanelekile yokwakhiwa kwayo. Izakhiwo ezihlukile ze-granite ziyenza ibe ukukhetha okuhle kakhulu...Funda kabanzi -

Ingabe ipulatifomu yokuntanta yomoya we-granite idinga ukusetshenziswa neminye imishini?

Ipulatifomu yokuntanta emoyeni ye-granite Iyini? Kufanele isetshenziswe kanjani? Ipulatifomu yokuntanta emoyeni ye-granite iyithuluzi elingathutha kalula izinto ezisindayo njengemishini nemishini. Ipulatifomu isebenzisa umoya ocindezelwe ukuphakamisa nokuhambisa izinto, okunciphisa umzamo nesikhathi esidingekayo ukuze...Funda kabanzi -

Yikuphi ukunaka okukhethekile okufanele kunikezwe ipulatifomu yokuntanta emoyeni we-granite?

Ipulatifomu yokuntanta emoyeni ye-granite iyinto ebalulekile esetshenziswa ezimbonini eziningi. Umsebenzi wayo oyinhloko ukuhlinzeka ngendawo ebushelelezi neqondile yokufakwa kwemishini esindayo nemishini, okubenza bakwazi ukusebenza kahle nangokuphumelelayo. Amapulatifomu okuntanta emoyeni we-granite ...Funda kabanzi -

Ingabe ipulatifomu yokuntanta yomoya we-granite idinga ukunakekelwa njalo?

Amapulatifomu okuntanta emoyeni we-granite ayisisombululo esisebenzayo sezinhlelo zokusebenza zezimboni nezentengiselwano. Lobu ubuchwepheshe obuthuthukisiwe obusebenzisa umoya ocindezelwe ukulengisa izinto ezisindayo emcamelweni womoya, okwenza kube lula ukuhambisa izinto ezinkulu nezisindayo. Kuvame ukusetshenziswa...Funda kabanzi