Ultra Precision Manufacturing Solutions

-

I-Granite Based Gantry System

I-Granite base Gantry System iphinde ibizwe nge-XYZ Three axis gantry slayidi ngesivinini esikhulu ezihambayo ngeplathifomu yokutholwa kokusika okuqondile.

Singakwazi ukwakha ukuhlanganiswa kwe-granite okunembayo kwe-Granite Based Gantry System, i-XYZ Granite Gantry Systems, i-Gantry System ene-Lineat Motors nokunye.

Siyakwamukela ukuthi usithumelele imidwebo yakho futhi uxhumane noMnyango wethu Wezobuchwepheshe ukuze Uthuthukise futhi uthuthukise ukwakheka kwemishini. Ulwazi olwengeziwe sicela uvakasheleikhono lethu.

-

I-Granite Surface Plate enokwesekwa kweKhabhinethi Yensimbi Eshiselwe

Sebenzisa i-Granite Surface Plate, ithuluzi lomshini, njll. ukubeka maphakathi nendawo noma ukusekela.

Lo mkhiqizo usezingeni eliphezulu ukumelana nomthwalo.

-

Usekelo olungasuseki

Ipuleti elingaphezulu limele ipuleti elingaphezulu: I-Granite Surface Plate kanye ne-Cast Iron Precision. Ibuye ibizwe nge-Integral metal support, ukwesekwa kwensimbi eshiselwe…

Kwenziwe kusetshenziswa impahla yepayipi yesikwele ngokugcizelela ukuzinza nokusebenziseka kalula.

Idizayinelwe ukuthi i-Surface Plate inembe kakhulu izogcinwa isikhathi eside.

-

Ithebula Le-Optic Vibration Insulated

Ukuhlolwa kwesayensi emphakathini wanamuhla wesayensi kudinga izibalo nezilinganiso ezinembe kakhulu. Ngakho-ke, idivayisi engakwazi ukuhlukaniswa ngokuqhathaniswa nemvelo yangaphandle kanye nokuphazamiseka kubaluleke kakhulu ekukalweni kwemiphumela yokuhlolwa. Ingakwazi ukulungisa izingxenye ezihlukahlukene ze-optical kanye nemishini yokuthwebula ngesibonakhulu, njll. Inkundla yokuhlola i-optical isiphenduke umkhiqizo okufanele ube nawo ekuhlolweni kocwaningo lwesayensi.

-

I-Precision Cast Iron Surface Plate

I-cast iron T slotted surface plate iyithuluzi lokulinganisa lezimboni elisetshenziswa kakhulu ukuvikela ucezu lokusebenza. Abasebenzi basebhentshini bayisebenzisela ukulungisa amaphutha, ukufaka, nokugcina izinto zokusebenza.

-

Usekelo olususekayo (Usekelo lwensimbi oluhlanganisiwe)

Ima - Ukuze ivumelane ne-Granite Surface Plates(1000mm kuya ku-2000mm)

-

I-Surface Plate Stand esinomshini wokuvimbela ukuwa

Lokhu kusekelwa kwensimbi kuwukwesekwa okwenziwe ngomthungi wepuleti lokuhlola legwadle lamakhasimende.

-

UJack Usethelwe I-Granite Surface Plate

I-Jack isethi ye-granite surface plate, engalungisa izinga le-granite surface plate kanye nobude. Ngemikhiqizo yosayizi ongaphezu kuka-2000x1000mm, phakamisa ukusebenzisa uJack (ama-5pcs ngesethi eyodwa).

-

I-UHPC eyenziwe ngomthungo (RPC)

Izicelo ezingenakubalwa ezihlukile ze-uhpc ye-high-tech material ayikabonakali. besilokhu sithuthukisa futhi sikhiqiza izixazululo ezifakazelwe yimboni zezimboni ezahlukahlukene ngokubambisana namakhasimende.

-

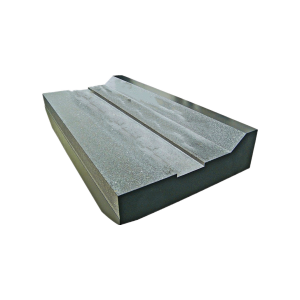

Umbhede Womshini Wokugcwalisa Amaminerali

Insimbi, eshiselwe, igobolondo lensimbi, nezakhiwo ezikhonjiwe zigcwaliswa ngokusansimbi okunciphisa ukudlidliza kwe-epoxy resin-bonded mineral.

Lokhu kudala izakhiwo eziyinhlanganisela ezinozinzo lwesikhathi eside ezinikeza nezinga elihle kakhulu lokuqina okumile nokuguquguqukayo.

Iyatholakala futhi ngezinto zokugcwalisa ezimunca imisebe

-

Umbhede Womshini Wokuphonsa Amaminerali

Sesimelwe ngempumelelo ezimbonini ezehlukene iminyaka eminingi ngezingxenye zayo ezithuthukisiwe zangaphakathi ezenziwe ngokusakazwa kwamaminerali. Uma kuqhathaniswa nezinye izinto, ukukhishwa kwamaminerali kubunjiniyela bemishini kunikeza izinzuzo ezimbalwa ezimangalisayo.

-

UKUSEBENZA OKUPHEZULU KANYE NOKUSIKA AMAMINERALI OWENZIWE NGOKWENZIWE

I-ZHHIMG® ye-mineral casting emibhedeni yemishini esebenza kahle kakhulu kanye nezingxenye zombhede womshini kanye nobuchwepheshe bokubumba obuphayona bokunemba okungenakuqhathaniswa. Singakwazi ukukhiqiza isisekelo somshini wokuphonsa amaminerali ahlukahlukene ngokunemba okuphezulu.