I-Granite iyinto eyingqayizivele ebilokhu isetshenziswa kumadivayisi okucubungula ngokunembile iminyaka eminingi. Yaziwa ngokuqina kwayo okuphezulu kanye nokukhula okuphansi kokushisa, okwenza ibe yinto efanelekile yokusetshenziswa ngokunembile.

Nazi ezinye izindlela zokusebenzisa izingxenye ze-granite mechanical kumadivayisi okucubungula ngokunemba:

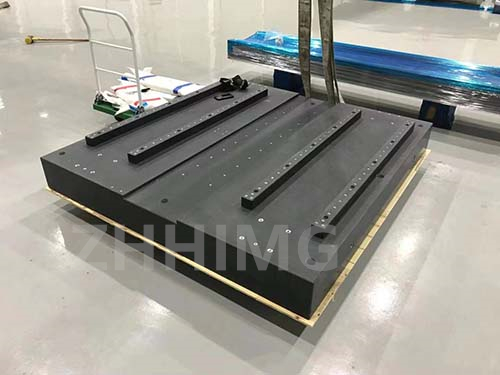

1. Amapuleti obuso be-granite

Amapuleti omhlaba we-granite asetshenziswa ekucubunguleni ngokunemba ukuqinisekisa ukuthi umsebenzi ubanjwe ekuphakameni nasekhoneni elifanele. Asetshenziswa ezinqubweni zomshini ezifana nokugaya nokugaya ukuqinisekisa ukuthi umsebenzi uyisicaba futhi uhambisana.

Amapuleti ongaphezulu e-granite angasikwa futhi afakwe ngomshini ngobukhulu obuqondile, okuqinisekisa ukuthi ayisicaba futhi aqondile. Kulula futhi ukuwahlanza nokunakekela, okwenza abe afanele ukusetshenziswa ekusetshenzisweni komshini onembile.

2. Izisekelo zomshini we-granite

Izisekelo zomshini we-granite zisetshenziswa emishinini enembile ukuze kuhlinzekwe isisekelo esiqinile nesiqinile somshini. Isisekelo se-granite sisiza ekumunceni ukudlidliza nokuqinisekisa ukuthi umshini usebenza kahle.

Izisekelo zomshini we-granite nazo zilungele ukusetshenziswa ezindaweni lapho ukulawulwa kokushisa kubalulekile khona. Ukwanda okuphansi kokushisa kwe-granite kusho ukuthi ayithinteki kakhulu yizinguquko zokushisa, okuqinisekisa ukuthi umshini ugcina ukunemba kwawo ngokuhamba kwesikhathi.

3. Ozimele begranite

Amafreyimu e-granite asetshenziswa kumadivayisi okulinganisa ngokunemba njengemishini yokulinganisa ehlanganisiwe (ama-CMM). Uhlobo oluqinile noluzinzile lwe-granite lwenza kube kuhle ukusetshenziswa kulezi zinhlelo zokusebenza, lapho ukunemba nokuqina kubaluleke kakhulu.

Amafreyimu e-granite nawo ayamelana nokuguguleka nokugqwala, okuqinisekisa ukuthi umshini ugcina ukunemba kwawo ngokuhamba kwesikhathi.

4. Amabheringi e-granite

Ama-granite bearings asetshenziswa emishinini enembile lapho kudingeka khona ukungqubuzana okuphansi kanye nokunemba okuphezulu. Lawa ma-bearings enziwe ngamabhulokhi e-granite aphansi futhi asetshenziswa ezinhlotsheni lapho ama-bearings avamile engeke anikeze ukunemba noma ukuqina okwanele.

Ama-granite bearings nawo alungele ukusetshenziswa ezindaweni lapho ukungcola kuyinkinga, njengoba evame ukuguguleka futhi adabukeke kancane kune-bearings yendabuko.

Ekuphetheni, izingxenye ze-granite mechanical ziyimpahla ebalulekile embonini yamadivayisi okucubungula ngokunembile. Azigcini nje ngokunikeza ukunemba, kodwa futhi nokuzinza, ukuqina, kanye nokumelana nokuguguleka nokugqwala. Ukwanda kwazo okuphansi kokushisa kanye nekhono lokumunca ukudlidliza kuzenza zibe yinto evelele uma kuqhathaniswa nezinye izinto. Njengoba ubuchwepheshe buthuthuka, isidingo semishini yokucubungula ngokunembile sizoqhubeka sikhula, futhi ukusetshenziswa kwezingxenye ze-granite mechanical kuzoba yisihluthulelo ekwakheni ikusasa lamadivayisi okucubungula ngokunembile.

Isikhathi sokuthunyelwe: Novemba-25-2023