I-Granite iyinto eyingqayizivele esetshenziselwe ukunemba ukucubungula amadivayisi iminyaka eminingi.Yaziwa ngokuqina kwayo okuphezulu kanye nokunwebeka okushisayo okuphansi, okuyenza ibe into efanelekile yokusetshenziswa okunembayo.

Nazi ezinye izindlela zokusebenzisa izingxenye zemishini ye-granite kumadivayisi okucubungula ngokunemba:

1. Amapuleti angaphezulu kwe-Granite

Amapuleti angaphezulu kwe-Granite asetshenziswa ekwenzeni imishini enembile ukuze kuqinisekiswe ukuthi ucezu lokusebenza lugcinwe endaweni ephakeme nange-engeli efanele.Zisetshenziswa ezinqubweni zemishini ezifana nokugaya nokugaya ukuze kuqinisekiswe ukuthi ucezu lokusebenza luyisicaba futhi luyahambisana.

Amapuleti angaphezulu kwegwadle angasikwa futhi afakwe ngomshini ukuze abe nezilinganiso ezinembile, kuqinisekiswe ukuthi ayisicaba futhi aqondile.Futhi kulula ukuwahlanza nokuyinakekela, okuwenza alungele ukusetshenziswa ezinhlelweni zemishini yokunemba.

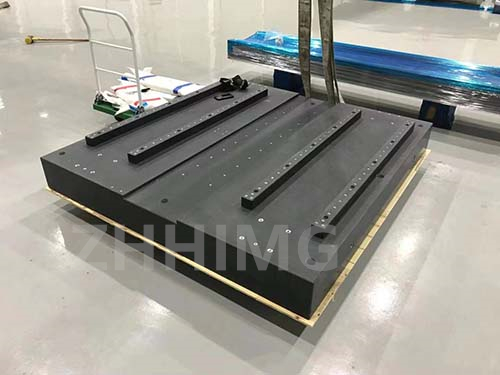

2. Izisekelo zomshini we-Granite

Izisekelo zomshini we-Granite zisetshenziswa emishinini enembayo ukuze kuhlinzekwe isisekelo esiqinile nesiqinile somshini.Isisekelo se-granite sisiza ukumunca ukudlidliza futhi siqinisekise ukuthi umshini usebenza kahle.

Izisekelo zomshini we-Granite nazo zilungele ukusetshenziswa ezinhlelweni lapho ukulawulwa kwezinga lokushisa kubalulekile.Ukunwebeka okuphansi kokushisa kwegwadle kusho ukuthi ayithinteki kangako ekushintsheni kwezinga lokushisa, okuqinisekisa ukuthi umshini ugcina ukunemba kwawo ngokuhamba kwesikhathi.

3. Amafreyimu e-Granite

Amafreyimu e-Granite asetshenziswa kumadivayisi okulinganisa anemba njengemishini yokulinganisa yokuxhumanisa (ama-CMM).Imvelo eqinile futhi ezinzile ye-granite iyenza ifaneleke ukusetshenziswa kulezi zinhlelo zokusebenza, lapho ukunemba nokuzinza kubaluleke kakhulu.

Amafreyimu e-granite nawo amelana nokuguga nokugqwala, okuqinisekisa ukuthi umshini ugcina ukunemba kwawo ngokuhamba kwesikhathi.

4. Ama-granite bearings

Ama-granite bearings asetshenziswa emishinini enembayo lapho kudingeka khona ukungqubuzana okuphansi nokunemba okuphezulu.Lawa mabheringi enziwe ngamabhulokhi egwadule aphansi futhi asetshenziswa ezinhlelweni lapho ama-bearings avamile engeke anikeze ukunemba okwanele noma ukuqina.

Ama-granite bearings nawo alungele ukusetshenziswa ezinhlelweni lapho ukungcola kuwukukhathazeka, njengoba ejwayele ukuguga futhi adabuke kunama-bearings wendabuko.

Sengiphetha, izingxenye zemishini ye-granite ziyimpahla ebalulekile embonini yedivayisi yokucubungula ukunemba.Abagcini nje ngokuhlinzeka ngokunemba, kodwa futhi nokuzinza, ukuqina, nokumelana nokugqoka nokugqwala.Ukunwebeka kwazo okuphansi kwe-thermal namandla okumunca ukudlidliza kuzenza zibe izinto ezigqamayo uma ziqhathaniswa nezinye izinto.Njengoba ubuchwepheshe buthuthuka, isidingo semishini enembayo sizoqhubeka sikhula, futhi ukusetshenziswa kwezingxenye zemishini ye-granite kuzoba ukhiye ekulolongeni ikusasa lamadivayisi okucubungula ngokunemba.

Isikhathi sokuthumela: Nov-25-2023