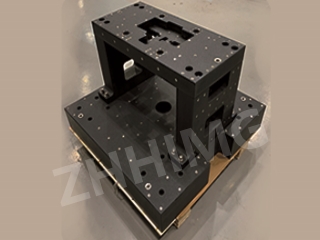

Isisekelo somshini we-Granite sesisetshenziswe ngokwandayo embonini yokucubungula i-wafer, ngenxa yezinzuzo zayo ezihlukahlukene ngaphezu kwezisekelo zemishini yendabuko njengensimbi nensimbi ekhonjiwe.Kulesi sihloko, sizoxoxa ngezinzuzo zokusebenzisa isisekelo somshini we-granite wemikhiqizo yokucubungula i-wafer.

Okokuqala, i-granite iyimpahla ezinzile futhi eqinile, enokumelana okuphezulu kakhulu nokuguqulwa nokudlidliza.Lokhu kuyenza ibe inketho ekahle yezisekelo zomshini ezidinga ukunemba okuphezulu nokunemba.Ekucutshungulweni kwe-wafer, noma yikuphi ukuhluka okuncane noma ukudlidliza kungaba nomthelela omkhulu kukhwalithi yomkhiqizo.Ngokusebenzisa isisekelo somshini we-granite, umshini uyakwazi ukufeza izinga elidingekayo lokunemba nokunemba, okuholela kukhwalithi yomkhiqizo engcono.

Okwesibili, i-granite ine-coefficient ephansi kakhulu yokunwetshwa kokushisa, okusho ukuthi ayikhuli noma ayinciphisi kakhulu ngokushintsha kwezinga lokushisa.Lokhu kubaluleke kakhulu embonini yokucubungula i-wafer, njengoba noma yiziphi izinguquko ezishisayo zingaholela ekungalungisweni kahle kwemishini futhi kubangele izinkinga ngokucutshungulwa kwe-wafer.Ngokusebenzisa isisekelo somshini we-granite, iqinisekisa ukuthi imishini ihlala iqondile futhi ikhwalithi yokucubungula i-wafer iyagcinwa.

Okwesithathu, i-granite inomthamo ophezulu kakhulu wokudambisa, okusho ukuthi ingakwazi ukumunca ukudlidliza futhi ikuvimbele ekuphazamiseni izingxenye zomshini.Ukudlidliza kungabangela umonakalo emishinini yokucubungula i-wafer, okuholela ekulungiseni okubizayo kanye nesikhathi sokuphumula.Ngokusebenzisa isisekelo somshini we-granite, inciphisa ubungozi bokulimala okuhlobene nokudlidliza futhi iqinisekisa impilo ende yomshini.

Okwesine, i-granite iwumsebenzi ongewona uzibuthe, okuyenza ifanelekele izinhlelo zokusebenza lapho ukuphazamiseka kazibuthe kungabangela izinkinga, njengasembonini ye-semiconductor.Lokhu kuqinisekisa ukuthi imishini ayiphazamisi izinqubo ezibucayi ezihilelekile ekudaleni izingxenye ze-wafer.

Okokugcina, i-granite iyimpahla eminyene kakhulu futhi eqinile, okwenza ukuthi imelane kakhulu nokuguga nokuklebhuka uma kuqhathaniswa nezinye izinto ezifana nensimbi nensimbi.Lokhu kusho ukuthi isisekelo somshini we-granite sihlala isikhathi eside futhi sidinga ukulungiswa okuncane, okuholela ekusebenzeni okuhlala isikhathi eside nokuthembekile.

Sengiphetha, izinzuzo zokusebenzisa isisekelo somshini we-granite wemikhiqizo yokucubungula i-wafer ayikwazi ukweqiwa.Ukuzinza, ukunemba, ukumelana nezinguquko ezishisayo, amandla okudambisa, izakhiwo ezingezona uzibuthe, nokuqina kuyenza ibe ukukhetha okuhle kakhulu ngezidingo eziyinselele zokucutshungulwa kwe-wafer.Ukusetshenziswa kwezisekelo zomshini we-granite ngokungangabazeki kuzozuzisa imboni ngokuthuthukisa ikhwalithi yemikhiqizo ye-wafer kanye nokunciphisa izindleko zokusebenza.

Isikhathi sokuthumela: Nov-07-2023