I-Granite iyitshe lemvelo elakhiwe ngokupholisa nokuqina kwe-magma yentaba-mlilo noma i-lava. Iyinto eqinile kakhulu futhi ehlala isikhathi eside emelana kakhulu nokuklwebheka, ukudaya, nokushisa. I-Granite isetshenziswa kakhulu embonini yokwakha ngezinto zokwakha ezifana nama-countertop, phansi, kanye nama-facade ngenxa yamandla ayo nokuqina kwayo. Ngaphezu kwalezi zinhlelo zokusebenza, i-granite iphinde yangena embonini yamadivayisi okuhlanganisa ngokunemba, lapho isetshenziswa kabanzi njengezinto eziyisisekelo.

Amadivayisi okuhlanganisa ngokunembile asetshenziswa ezimbonini ezahlukahlukene njengezimoto, izindiza, kanye nezokwelapha, lapho amazinga aqinile okunemba nokuthembeka kubalulekile khona. Kudingeka izinto eziyisisekelo zala madivayisi ezinganikeza ukudambisa ukudlidliza okuhle kakhulu, ukuqina okuphezulu, kanye nokuqina kokushisa. I-Granite ihlangabezana nazo zonke lezi zidingo, okwenza kube ukukhetha okuhle kwesisekelo samadivayisi okuhlanganisa ngokunembile.

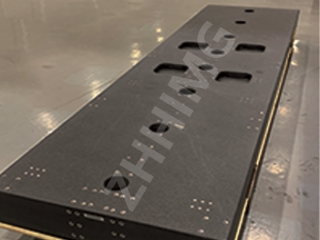

Enye yezindlela eziyinhloko zokusebenzisa i-granite kumadivayisi okuhlanganisa ngokunemba iwukukhiqizwa kwemishini yokulinganisa ehlanganisiwe (ama-CMM). Ama-CMM asetshenziswa ezitshalweni zokukhiqiza ukukala ubukhulu bezingxenye ngezinga eliphezulu lokunemba. Le mishini isebenzisa isisekelo se-granite ngoba inikeza ipulatifomu ezinzile nethembekile yesistimu yokulinganisa. I-Granite ine-coefficient ephansi kakhulu yokwanda kokushisa, okusho ukuthi imelana kakhulu nokushintsha kwezinga lokushisa. Lokhu kuyenza ibe yinto efanelekile yokugcina ukunemba kwesistimu yokulinganisa.

I-Granite isetshenziswa kabanzi ekukhiqizweni kwezinhlelo zokuqondanisa ze-optical. Lezi zinhlelo zisetshenziselwa ukuvumelanisa izingxenye ze-optical zibe sezingeni eliphezulu kakhulu lokunemba. Izinto eziyisisekelo ze-granite zibalulekile kulezi zinhlelo ngoba zinikeza izinga eliphezulu lokuqina, okudingekayo ukuze kugcinwe ukuhambisana kwezingxenye ze-optical. I-Granite iphinde imelane kakhulu nokudlidliza, okwenza kube kuhle ukusetshenziswa ezindaweni lapho amazinga okudlidliza ephezulu khona, njengezitshalo zokukhiqiza.

Okunye ukusetshenziswa kwe-granite kumadivayisi okuhlanganisa ngokunemba kusekukhiqizweni kwemishini yokukhiqiza ye-semiconductor. Ukukhiqizwa kwe-semiconductor kudinga izinga eliphezulu lokunemba ukuqinisekisa ukuthi izingxenye zakhiwe ngezindinganiso eziqinile. Isisekelo se-granite sinikeza ukuzinza nokuqina okudingekayo kwemishini yokukhiqiza, okusiza ukuqinisekisa ukuthi izingxenye zakhiwe ngezidingo ezidingekayo.

Ngaphezu kwalezi zinhlelo zokusebenza, i-granite isetshenziswa nasekukhiqizweni kwemishini yelabhorethri, njengezilinganiso zokulinganisa kanye nemishini ye-spectroscopy. Lawa madivayisi adinga izinga eliphezulu lokuzinza ukuqinisekisa ukulinganisa okunembile. Isisekelo se-granite sinikeza ukuzinza nokuqina okudingekayo kwalezi zinhlobo zamadivayisi, okwenza kube ukukhetha okuhle.

Ekuphetheni, i-granite iyinto eguquguqukayo kakhulu esetshenziswe kabanzi embonini yobunjiniyela bokunemba. Izakhiwo zayo zokuqina okuphezulu, ukudambisa ukudlidliza, kanye nokuzinza kokushisa kwenza kube ukukhetha okuhle kwezinto eziyisisekelo zamadivayisi okuhlanganisa ngokunemba. Kusukela kuma-CMM kuya kumishini yokukhiqiza ye-semiconductor, i-granite isithole indlela yayo ezinhlobonhlobo zezicelo, okusiza ukuqinisekisa ukuthi amadivayisi akhiqizwe ngezindinganiso eziqinile zokunemba nokuthembeka. Njengoba isidingo sezingxenye ezinembile kakhulu siqhubeka sanda, kungenzeka ukuthi ukusetshenziswa kwe-granite kubunjiniyela bokunemba kuzoqhubeka nokukhula.

Isikhathi sokuthunyelwe: Novemba-21-2023